High-voltage vacuum extinction chamber

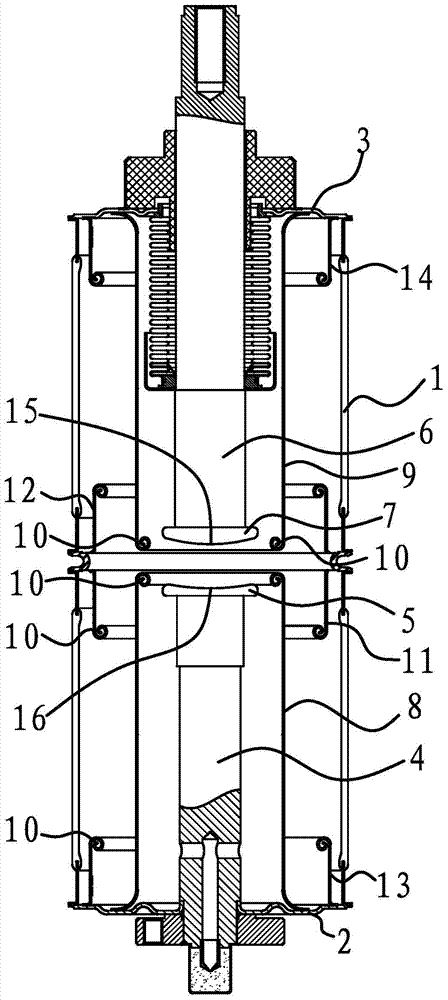

A vacuum interrupter and high-voltage technology, which is applied in high-voltage air circuit breakers, high-voltage/high-current switches, electrical components, etc., can solve the problem of reduced breaking current capability, tip current containment, and moving contacts that cannot be 1% Guarantee and other issues to achieve the effect of improving life, improving the ability to disconnect current, and avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

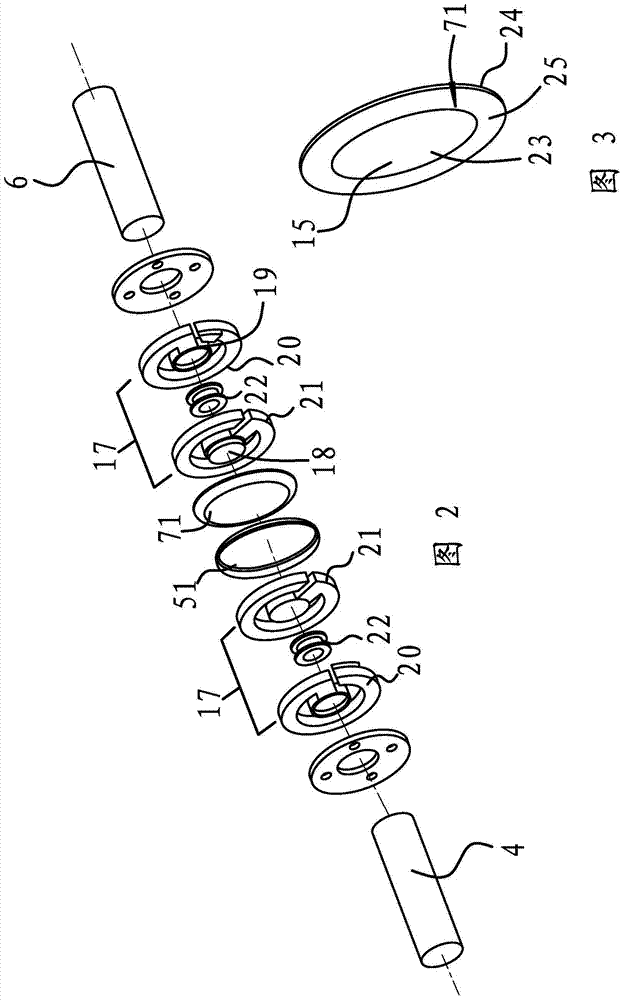

[0030] The content of embodiment 2 is basically the same as that of embodiment 1, the difference is that the adjustment structure includes a spherical positioning surface 15 arranged on the movable contact 7 and a hemispherical concave surface provided on the static contact 5, the hemispherical concave surface The radius of the ball is larger than that of the spherical positioning surface 15, and the spherical positioning surface 15 is opposite to the hemispherical concave surface.

[0031] In addition to these structures, it is also possible to reverse the above-mentioned structures. More broadly, the shape of the top block can be designed as a convex shape with a rounded surface, which can minimize the condition of tip discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com