Braided rope drawing method, porous membrane manufacturing method, and braided rope supplying device

A technology of porous membrane and manufacturing method, applied in chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of inability to supply hollow ropes, rising tension of support body supply, support body supply, etc., and achieve excellent process stability, Suppresses the effect of kinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0118] A first embodiment of the method for producing a porous membrane (also referred to as a porous hollow fiber membrane) of the present invention will now be described in detail with reference to the drawings.

[0119] The method for producing a porous membrane according to the first embodiment of the present invention includes a step of pulling out a hollow braided support body from the storage container by using the storage container as a winding tool (pulling step); A process of coating the membrane-forming stock solution on the outer peripheral surface of the braided support and solidifying the molding stock solution to form a porous membrane layer on the outer peripheral surface of the braided support (coagulation step).

[0120]

[0121] (braided rope support body)

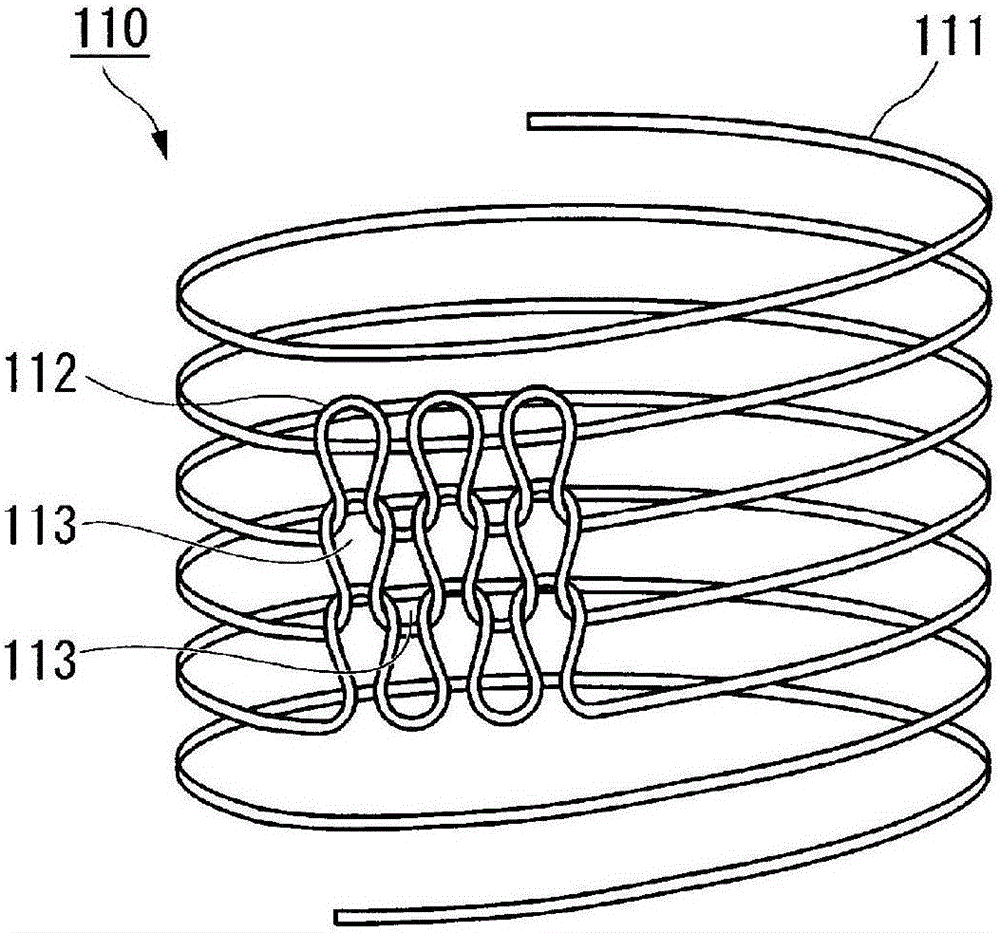

[0122] figure 1 The structure of the braided support body 110 used in this invention is shown.

[0123] The braided support body 110 is a cylindrical (hollow) braided cord in which one yarn 111 is ro...

no. 2 approach

[0276] Next, a second embodiment of the method for producing a porous membrane of the present invention will be described in detail with reference to the drawings.

[0277] In the manufacturing method of the porous membrane of this invention which concerns on 2nd Embodiment, it differs from 1st Embodiment mentioned above in the point which uses a bobbin as a winding tool. The other configurations are the same as those of the first embodiment, so descriptions thereof are omitted.

[0278] (Winding method of the braided rope support body on the winding frame)

[0279] For an example of the winding method of the braided rope support body on the bobbin frame, use Figure 12A with Figure 12B Be explained.

[0280] Figure 12A It is a schematic configuration diagram showing an example of a winding device used when winding a braided cord support body around a bobbin. The winding device 180a of this example has: the bobbin 170 on which the braided rope support body 110 is wound;...

Embodiment approach

[0304] In the second embodiment, the winding of the braided support body on the bobbin is not limited to the method described above. in use Figure 12A In the method of winding device 180a shown, the central axis direction of bobbin 170 is made horizontal to wind braided rope support body 110, but it is also possible to use, for example, Figure 9 The winding device 180b shown in (b) makes the central axis direction of the bobbin 170 vertical, and winds up the braided rope support body 110 as follows.

[0305] Figure 12B The illustrated winding device 180b includes: a bobbin frame 170; a supply guide 182 for supplying the braided rope support body 110 to the bobbin frame 170; A guide fixing fitting 183 capable of reciprocating movement in the central axis direction of the bobbin 170 .

[0306] In the method of winding the braided rope support body 110 on the bobbin 170 using the winding device 180b, first, the bobbin 170 is wound in a state where the center axis direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com