Screw expander

A screw expander and screw technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as low power generation efficiency, impracticality, and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

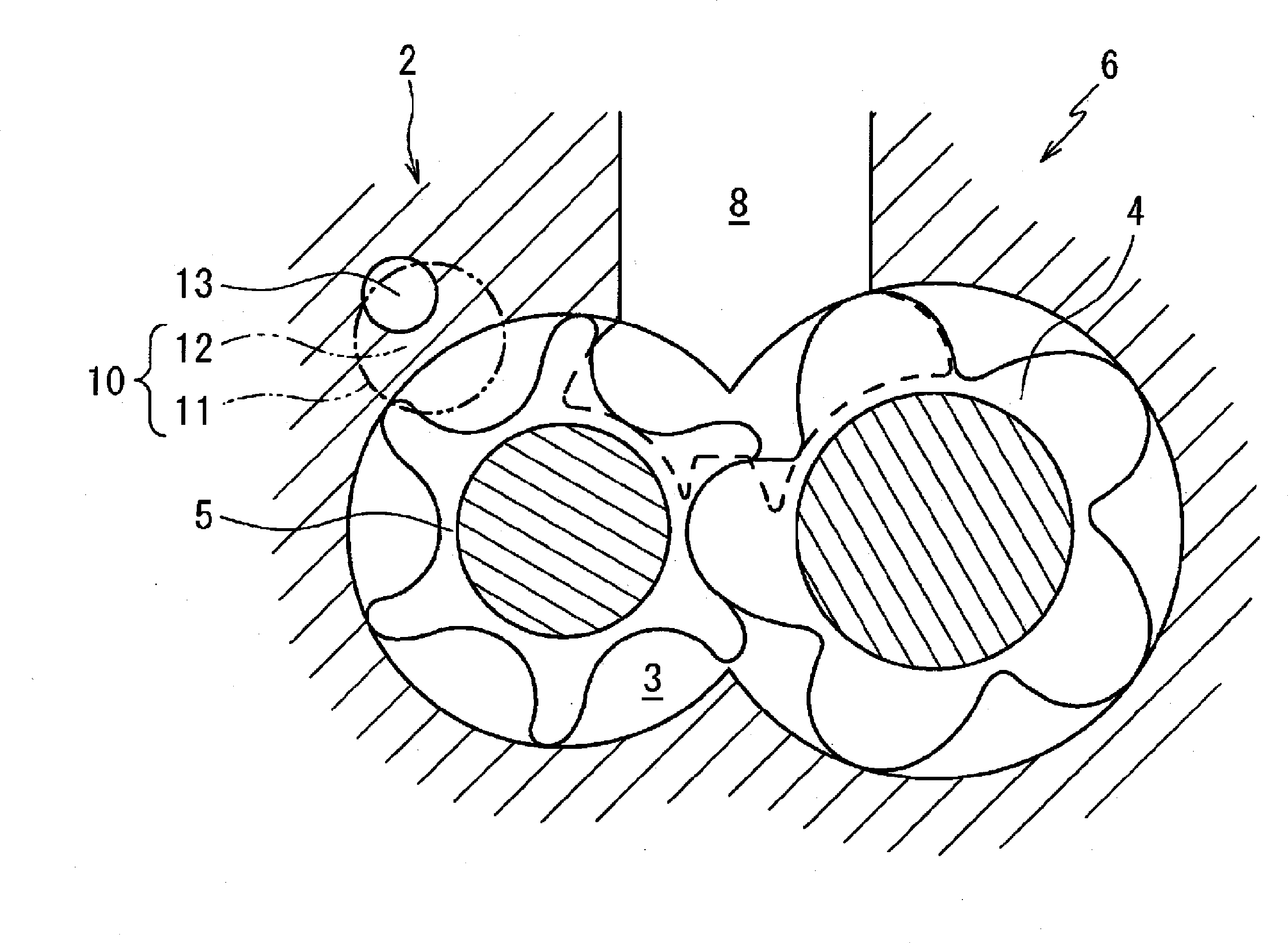

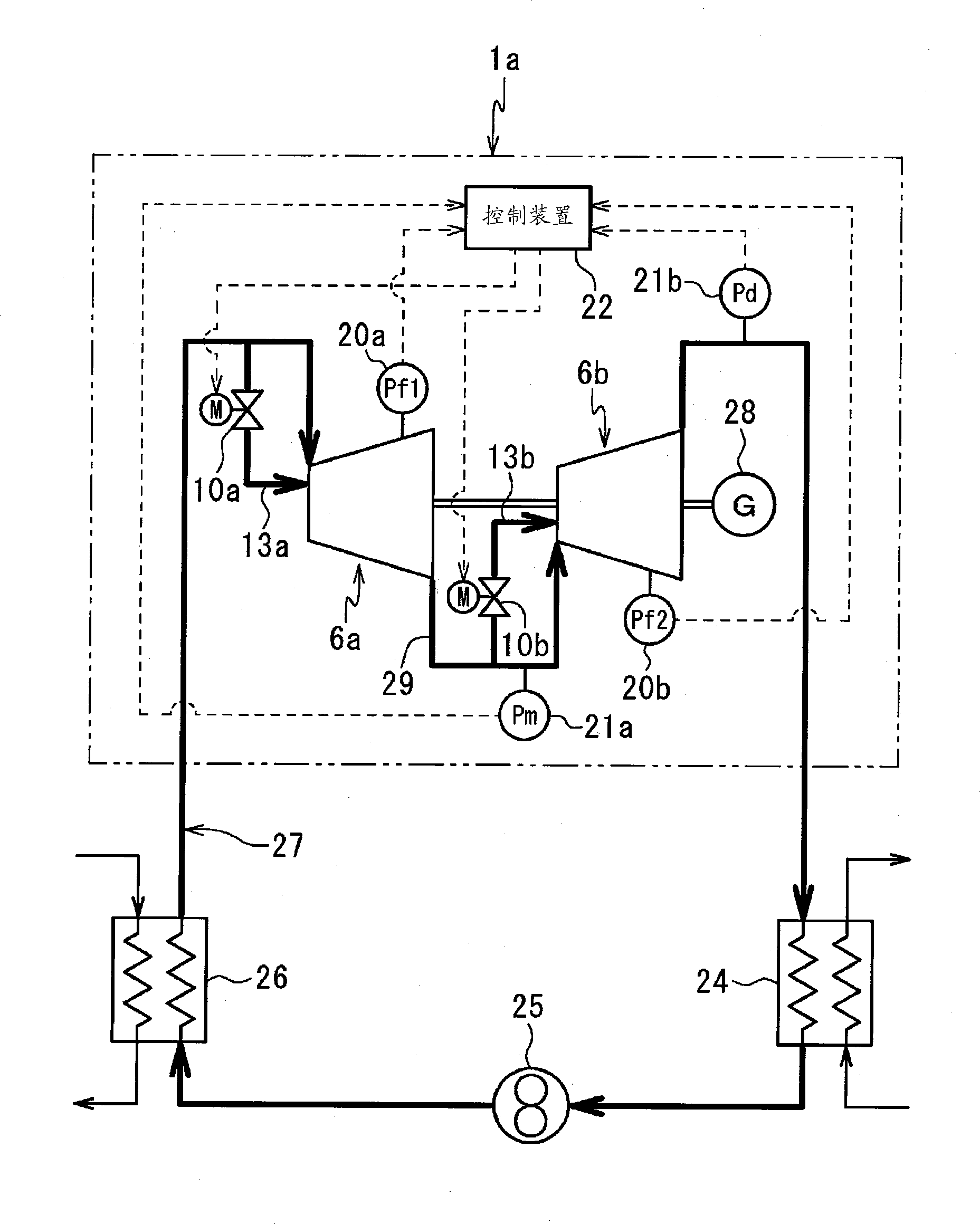

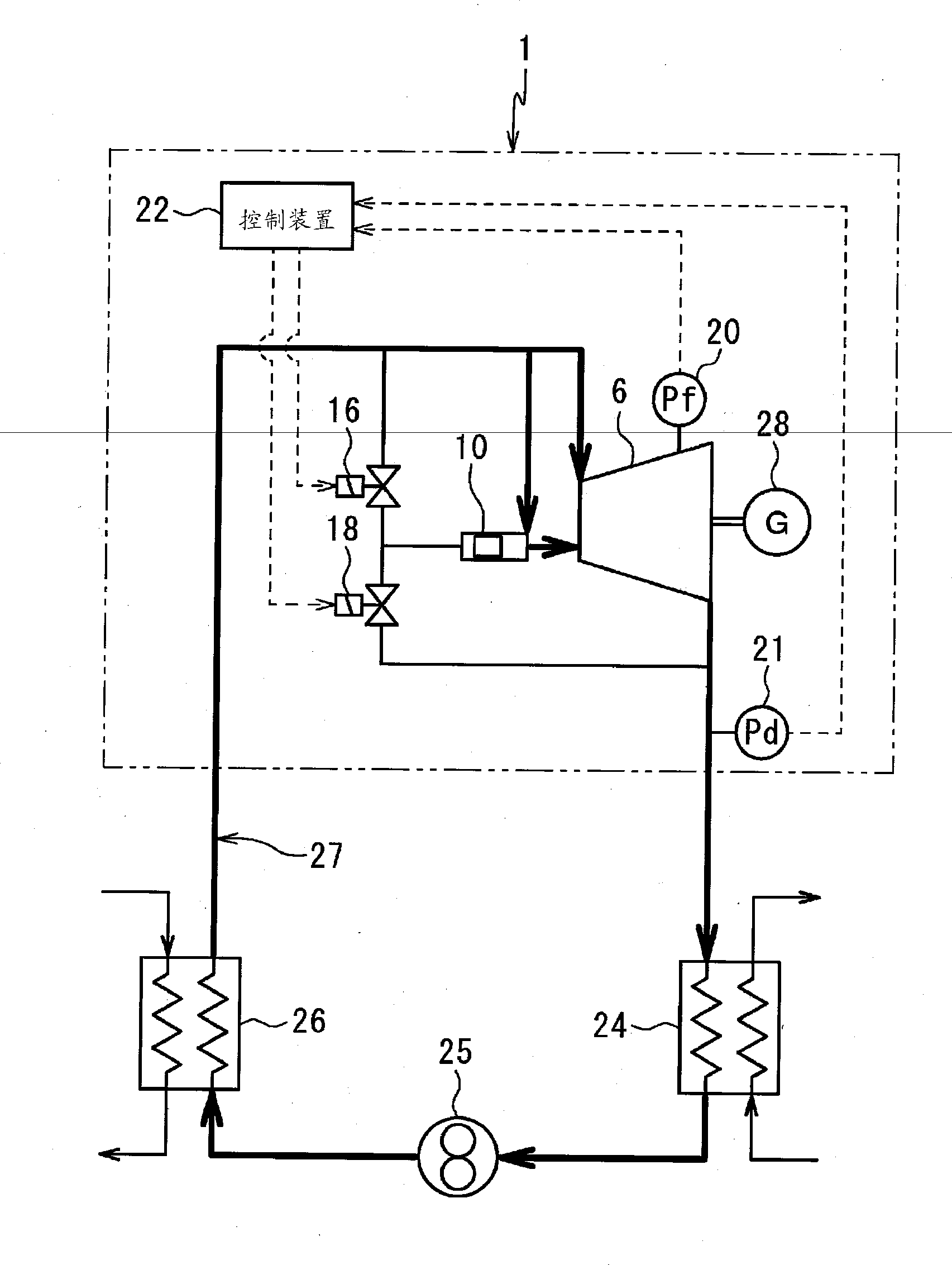

[0025] Hereinafter, embodiments of the present invention will be described with reference to the drawings. exist figure 1 In , the screw expander 1 as the first embodiment of the present invention is shown.

[0026] The screw expander 1 has an expander main body 6 that accommodates a pair of male and female screw rotors 4 , 5 engaged with each other in a rotor chamber 3 formed in a housing 2 . A high-pressure gas is supplied to the rotor chamber 3 from a gas supply path 8 connected to the external flow path 7 . And, the gas is exhausted from the rotor chamber 3 through the exhaust flow path 9 .

[0027] The screw rotors 4 and 5 divide the space in the rotor chamber 3 by their teeth, and define a plurality of expansion spaces between the supply flow path 8 and the exhaust flow path 9 . The volume of the expansion space gradually increases from the supply flow path 8 toward the exhaust flow path 9 as the screw rotors 4 and 5 rotate. Therefore, the screw rotors 4 and 5 are ro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap