Constant velocity universal joint

A constant velocity universal joint and guide groove technology, applied in the direction of gear transmission mechanism, elastic coupling, clutch, etc., can solve the problems of constant velocity universal joint enlargement, shoulder defect, uneven depth of guide groove, etc. Achieve the effects of avoiding enlargement, preventing shoulder defects, and realizing load capacity and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

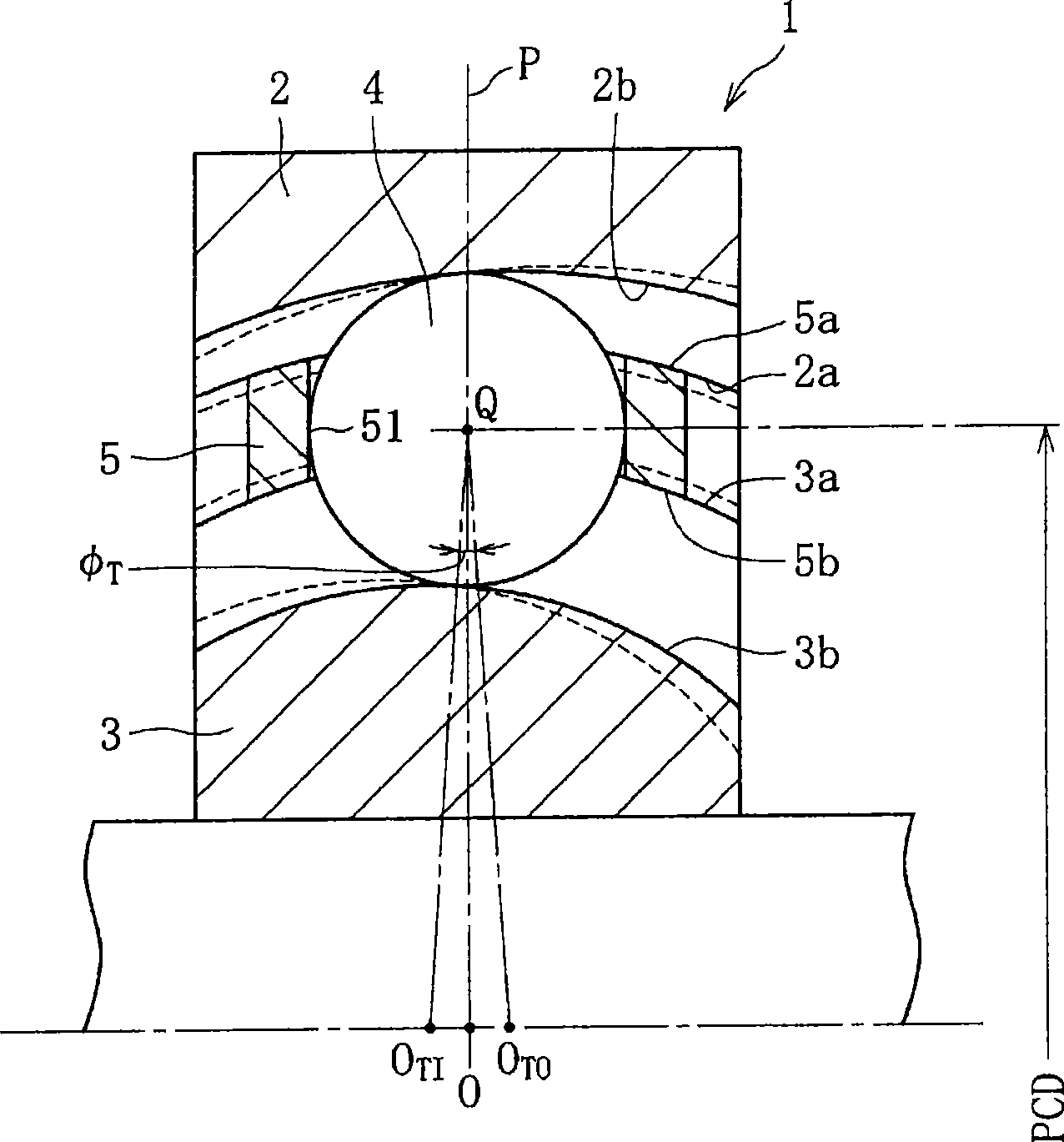

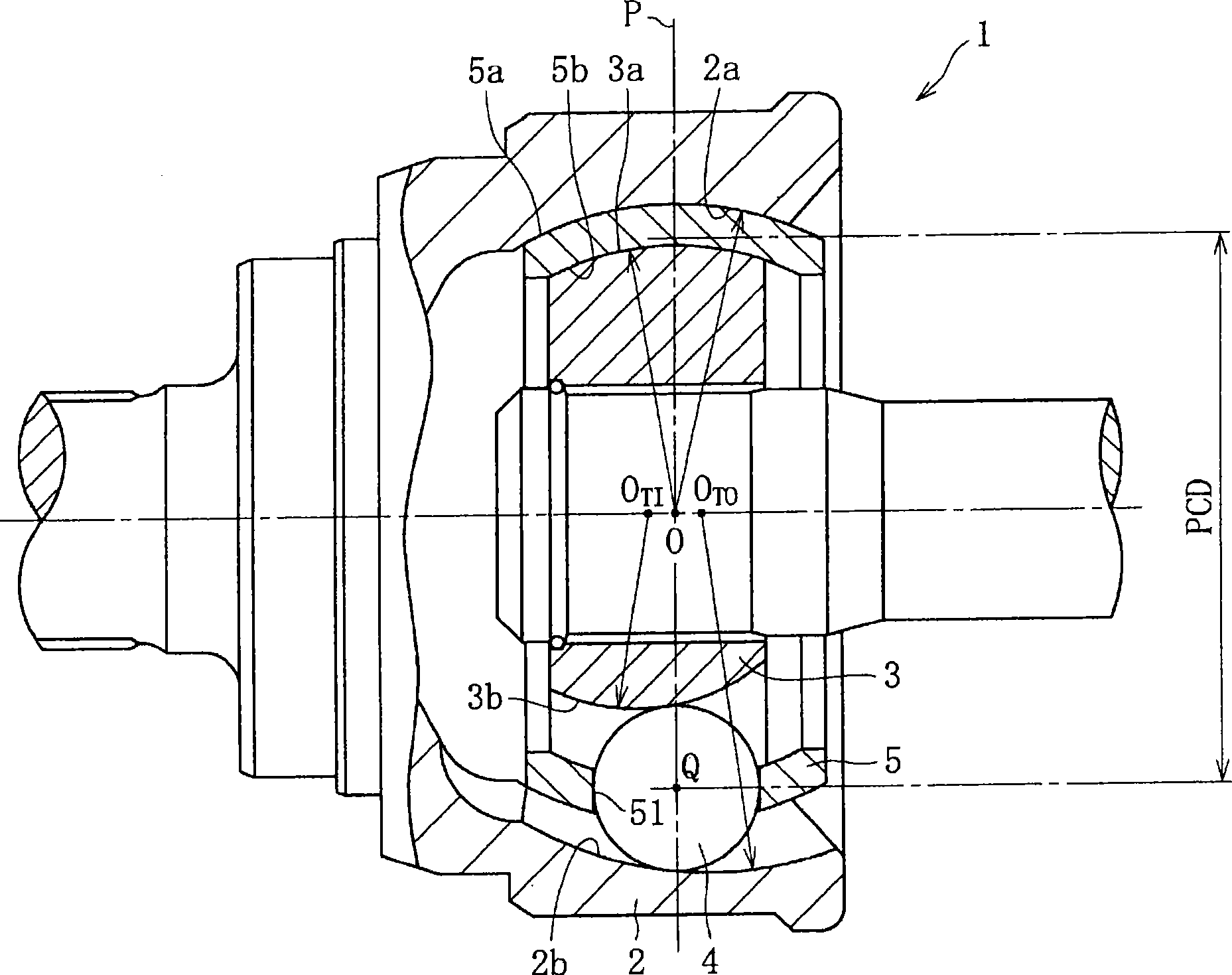

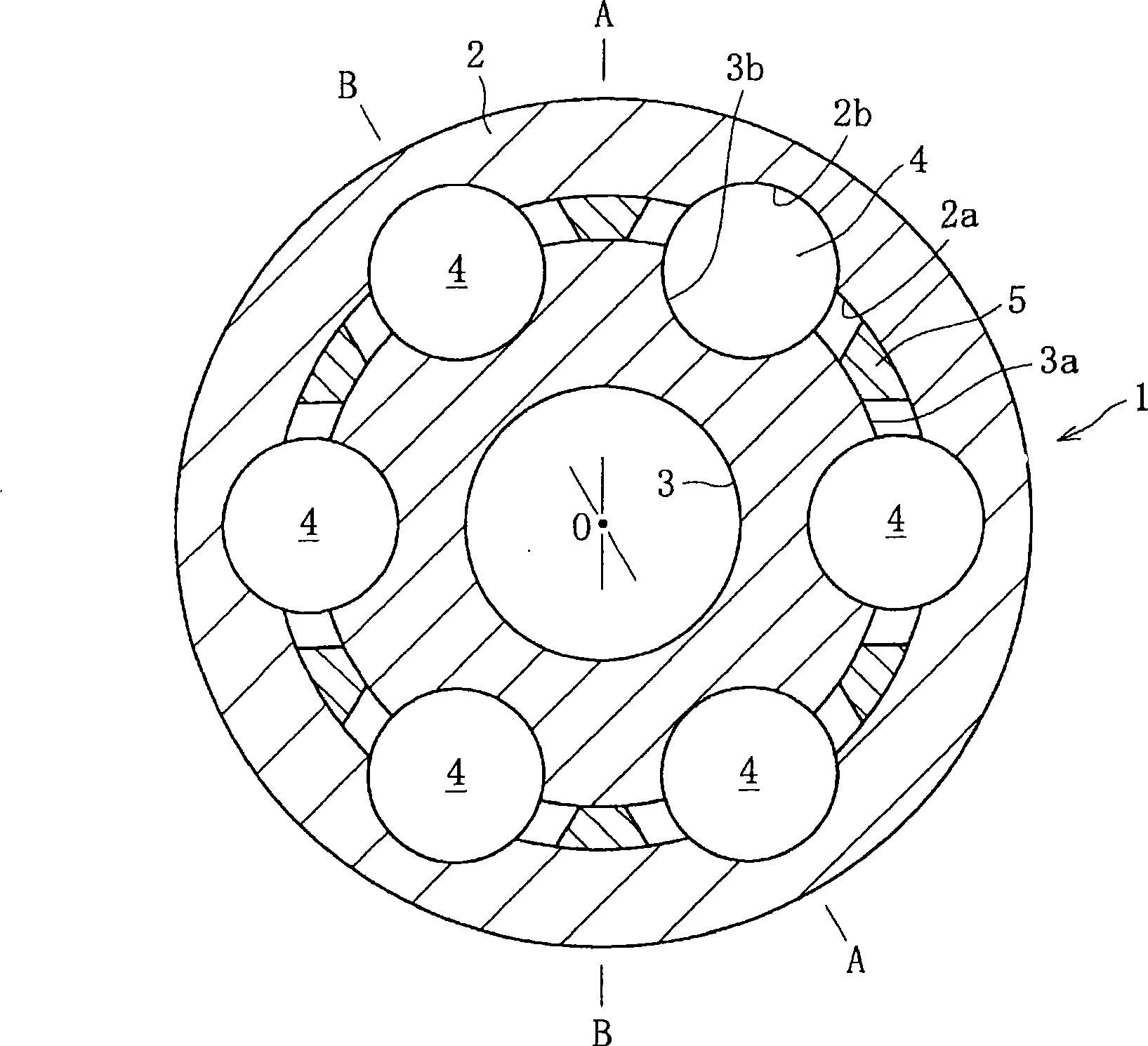

[0048] Such as Figure 1 ~ Figure 3 As shown, the constant velocity universal joint 1 of this embodiment includes: an outer member 2 (outer ring), an inner member 3 (inner ring), torque transmission balls 4 and a cage 5, wherein the outer member 2 is spherical A plurality of (usually 6) curved guide grooves 2b are formed along the axial direction on the inner peripheral surface 2a, and a plurality of (usually 6) curved guide grooves 2b are formed on the spherical outer peripheral surface 3a of the inner member 3 along the axial direction. ) Curved guide grooves 3b, and the torque transmission balls 4 are respectively disposed on the raceways formed by the cooperation of the guide grooves 2b of the outer member 2 and the guide grooves 3b of the inner member 3, and the cage 5 holds the torque transmission balls 4.

[0049] Center O of guide groove 2b of outer p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap