A continuous multi-stage winnowing and grading box, device and system for dry aggregate of concrete

A grading box and multi-stage air technology, which is applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve the problem of not meeting the requirements for aggregate grading of different particle sizes and reducing the quality of finished concrete Quality, low aggregate content and other problems, to achieve the effect of eliminating washing and dehydration steps, improving quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

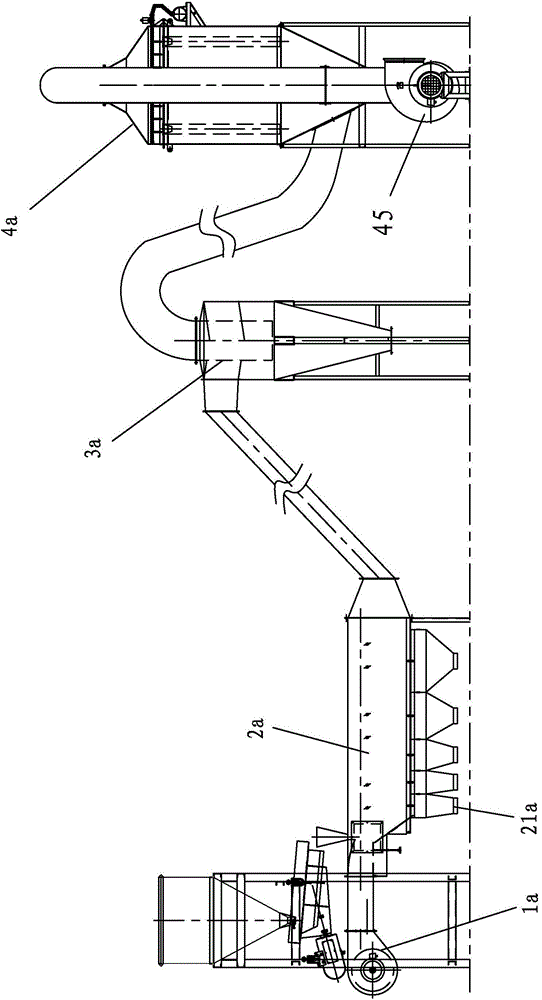

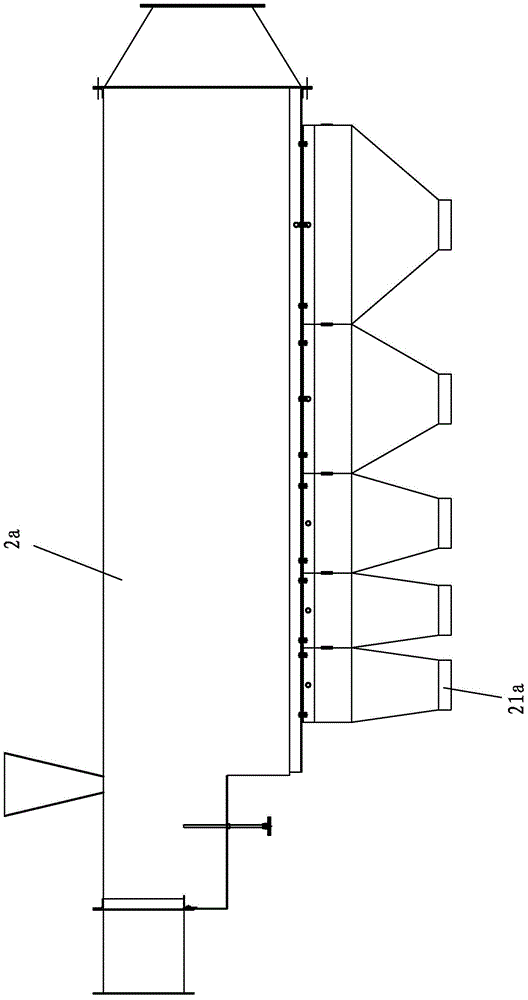

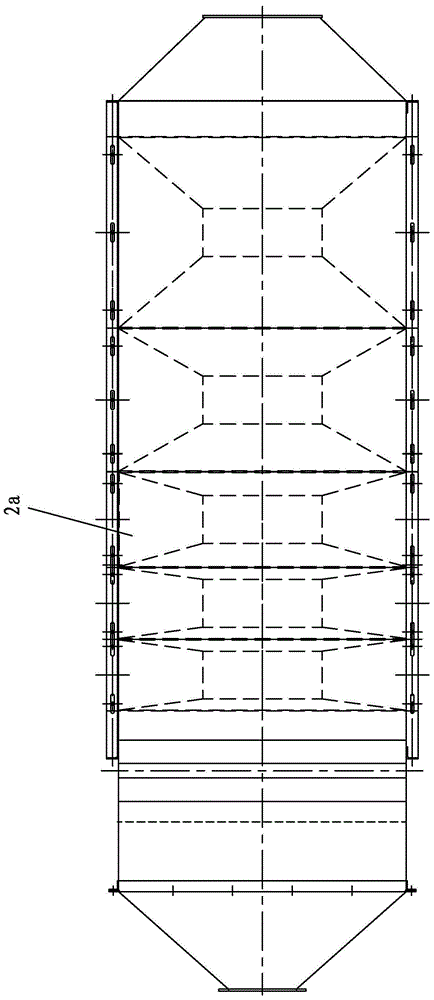

[0057] like Figure 4a to Figure 8 As shown, a continuous multi-stage winnowing and grading system for dry aggregate of concrete of the present invention includes a continuous multi-stage winnowing and classifying device 10 , a blower 20 , a cyclone filter 30 and a dust collection filter 40 successively.

[0058] The continuous multi-stage winnowing and classifying device 10 includes a dropping hopper 11 , a kneading deslimer 12 , a continuous multi-stage winnowing and classifying box 13 and a receiving bin 14 successively.

[0059] The falling hopper 11 is bucket-shaped, and the feed port corresponding to the rubbing deslimer 12 is arranged above the rubbing deslimer 12 . The aggregate is thrown into the drop hopper 11 through other feeding mechanisms, and then enters the rubbing deslimer 12.

[0060] The kneading deslimer 12 can adopt the following two implementations. One of the implementations is as Image 6 and Figure 7 As shown, the rubbing deslimer 12 includes a ca...

Embodiment 2

[0093] like Figure 4a , Figure 4b and Figure 5 As shown, the main difference between the present embodiment and the first embodiment is that the induced draft fan 50 is used instead of the air blower 20, and the induced draft fan 50 is installed at the air discharge port of the dust collecting and filtering equipment 40, and the lower air inlet 131e of the lower winnowing classification box 131b is open . The induced draft fan 50 in this embodiment can be set independently, or utilize the induced wind attached to the dust collecting and filtering equipment 40 .

[0094] The air outlet of the induced draft fan 50 is connected to the air outlet of the dust collecting and filtering equipment 40 in the production line, and the air outlet of the induced draft fan 50 is connected to the upper air inlet 131c. Select the classification box 131a. Through the suction effect of the induced draft fan 50, the wind pressure and air volume of the same intensity are formed in the lower...

Embodiment 3

[0098] The main difference between this embodiment and Embodiment 1 is that the air outlet of the blower 20 is respectively connected to the upper air inlet 131c and the lower air inlet 131e through the air duct.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com