Mandrel and processing method for inspection of Shobling lathe

A processing method and mandrel technology, applied in the field of ultra-high-precision lathe inspection tools, can solve the problems of unavailable, no inspection tools, and inability to complete inspection work, such as high-precision operation of machine tools, to achieve the effect of ensuring high-precision operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Taking the inspection mandrel for processing 180 Shoblin lathe as an example, the precision standard of Shoblin lathe is that the axial movement of the spindle is ≤0.005mm, and the radial runout is ≤0.005mm.

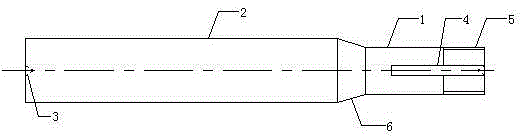

[0015] Such as figure 1 As shown, the quenched and ice-cooled No. 45 steel bar is processed by a precision lathe into a small cylindrical tapered handle 1 with a diameter of 24.99+0.01mm and a length of 76.52±0.01mm, and a large one with a diameter of 33.85+0.01mm and a length of 200±0.1mm. Cylinder datum axis 2, a connecting body with 165±1° chamfer 6 at the junction of the two cylinders, a 45° central taper hole 3 at both ends, and a clamp on the outer cylindrical surface at the end of the taper shank 1 that is compatible with the Schoblin lathe The keyway 4 with the same size as the fixed key and the external thread 5 with the same size as the threaded rod in the fixture are provided in the middle, and then the reference shaft 2 is finished with a mirror lathe,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com