A bearing adapter sleeve with a double-layer tightening structure

An adapter sleeve and tightening technology, applied in the direction of bearings, shafts and bearings, bearing components, etc., can solve the problems of short service life of bearing adapter sleeves, fretting corrosion, etc., to extend the service life, improve stability, use low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

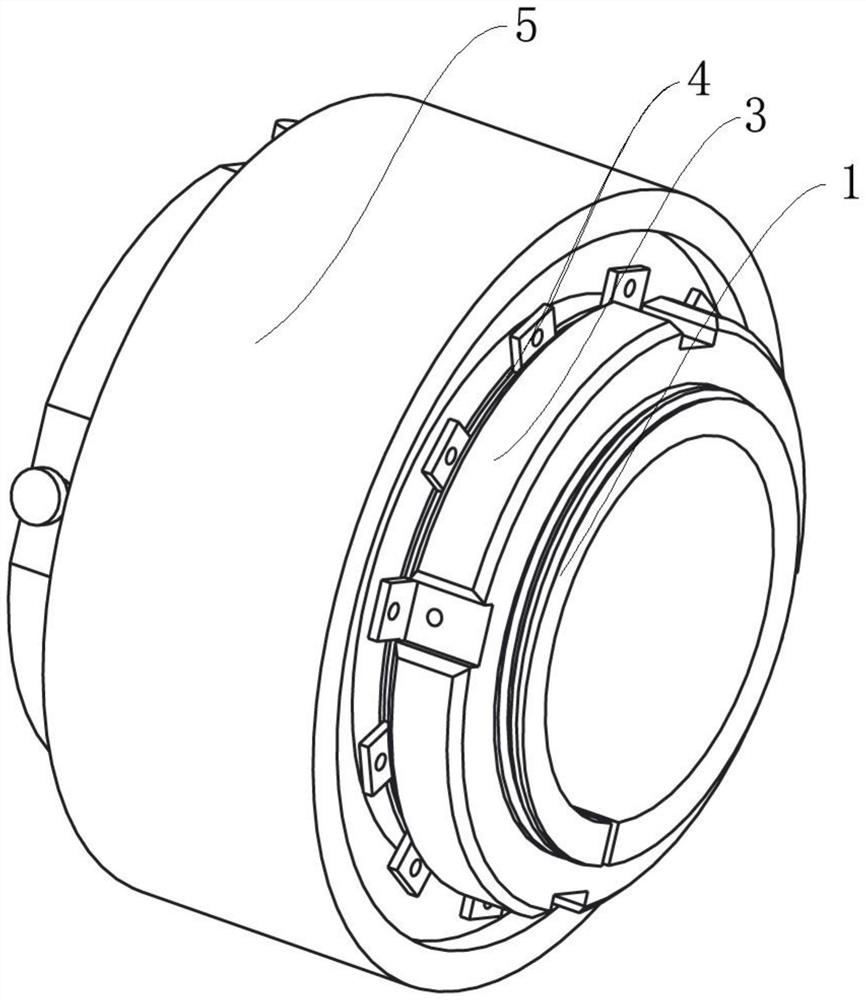

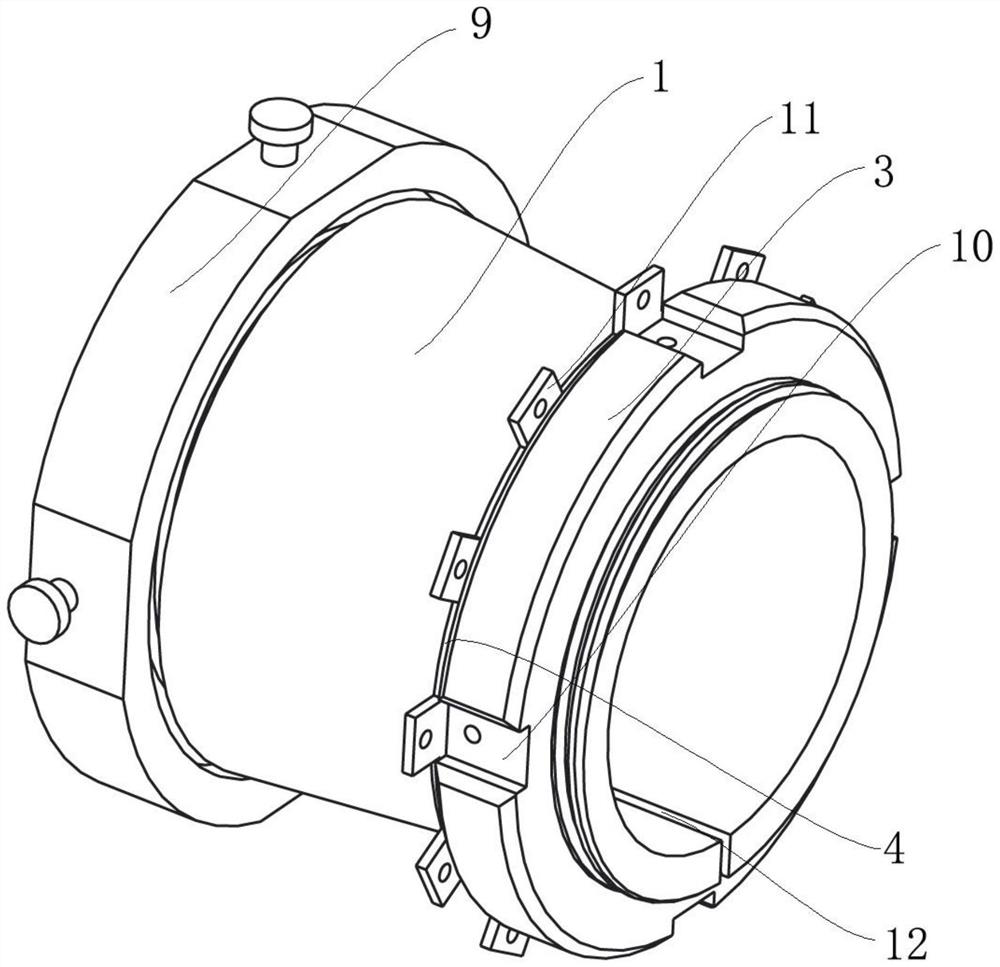

[0030] A bearing adapter sleeve with a double-layer tightening structure according to an embodiment of the present invention, such as Figure 1 to Figure 6 As shown, it includes adapter sleeve body 1 and adapter inner sleeve 2, adapter sleeve body 1 includes inner sleeve locking part 8, bearing fixing part 6 and nut locking part 7, bearing fixing part 6 and nut locking part 7 Set in the outer ring of the adapter sleeve main body 1 in turn, the bearing fixing part 6 is used to sleeve the bearing 5, the nut locking part 7 is provided with a lock nut 3, and the bearing 5 is fixed on the bearing fixing part 6 through the lock nut 3 On the other hand, the inner sleeve locking part 8 is arranged at one end close to the bearing fixing part 6, and the inner sleeve locking part 8 is located in the inner ring of the main body of the adapter sleeve 1, and the inner sleeve 2 is connected with the main body of the adapter sleeve through the inner sleeve locking part 8 1 fixed installation;...

Embodiment 2

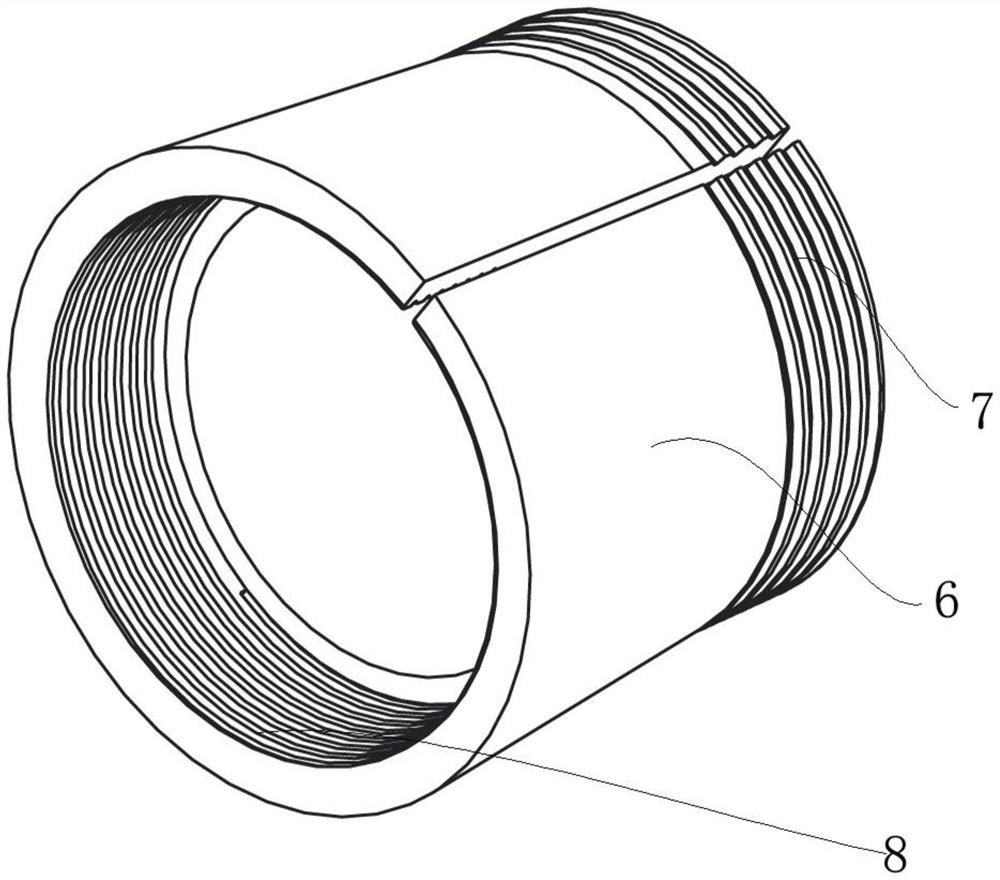

[0034] Compared with embodiment 1, in this embodiment, as image 3 , Figure 4 and Figure 5 As shown, the outer ring of the adapter sleeve 2 is a truncated cone, and the taper of the outer wall of the adapter sleeve 2 is slightly larger than the taper of the inner wall of the locking part 8 of the inner sleeve. When the adapter sleeve main body 1 and the adapter sleeve 2 are socketed Since the taper of the inner wall of the inner sleeve locking part 8 on the main body 1 of the adapter sleeve is relatively small, the inner sleeve locking part 8 has a greater pressing effect on the inner sleeve 2, so that the inner sleeve 2 and the tighter sleeve The fixation between the main body 1 of the adapter sleeve is more firm and reliable, and at the same time, the degree of tightness of the adapter inner sleeve 2 to the optical axis is increased to a certain extent, thereby improving the degree of tightness of the adapter sleeve main body 1 to the optical axis. The bearing is installe...

Embodiment 3

[0036] Compared with embodiment 1, in this embodiment, as Image 6 As shown, the locking groove 10 and each locking piece are provided with screw holes, after the locking piece is bent and engaged with the locking groove 10, the locking piece can be fixed in the locking groove 10 by screws On the other hand, the fixation strength of the lock washer 4 to the lock nut 3 is further improved by means of screw fixing, so as to ensure that the lock nut 3 will not loosen or fall off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com