Method for monitoring unbalanced force of sliding bearings of supergravity centrifugal machine

A sliding bearing and dynamic unbalance technology, applied in centrifuges and other directions, can solve the problems of inability to reflect the end bearing of the rotating arm, increase the complexity of the main structure, and unsafe monitoring results, so as to reduce dependence and have a wide range of applications. 、Reliable and stable measurement value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0065] Embodiments of the present invention and its implementation process are as follows:

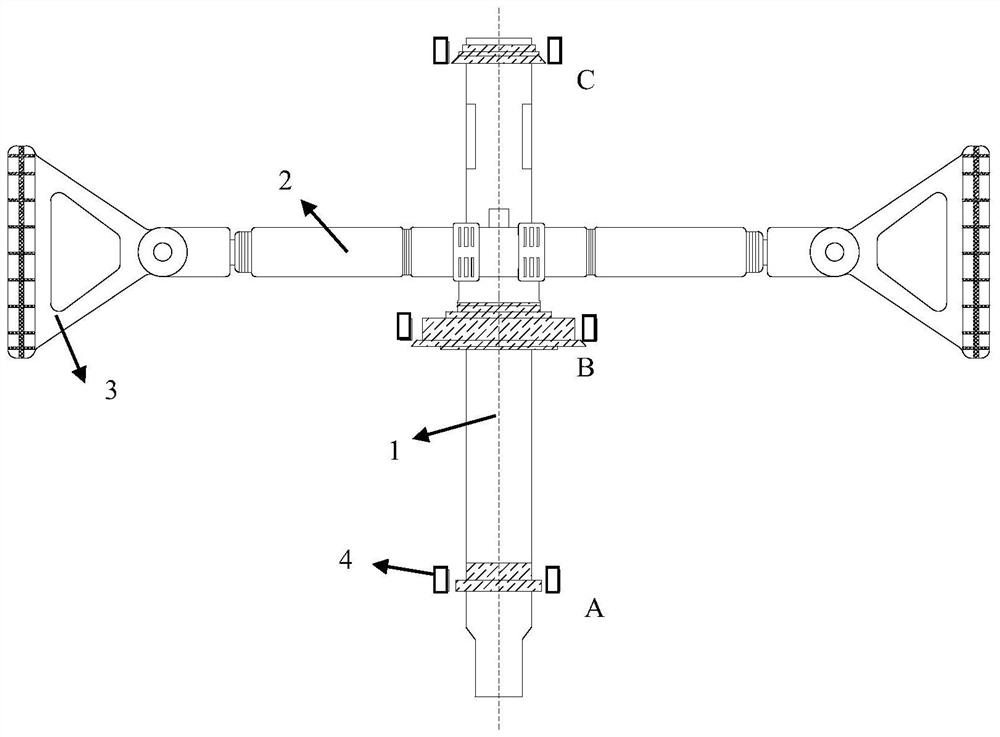

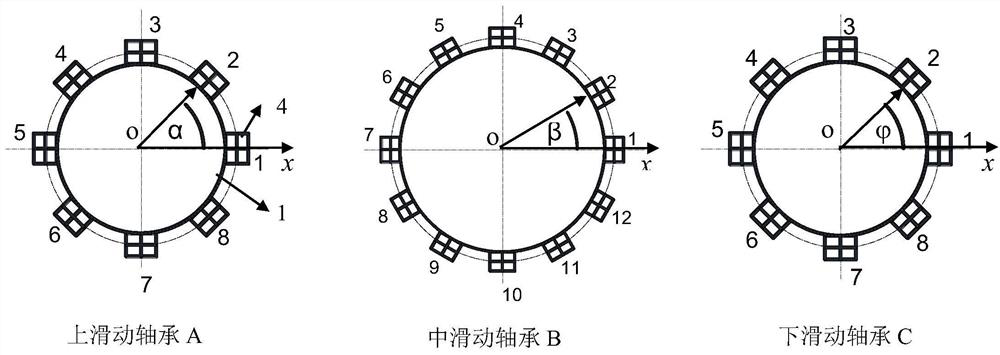

[0066] like figure 1 As shown, the supergravity centrifuge includes a main shaft 1, a rotating arm 2 and a hanging basket 3; the main shaft 1 of the supergravity centrifuge is equipped with an upper sliding bearing C, a middle sliding bearing B and a lower sliding bearing A in the upper, middle and lower parts respectively; The upper sliding bearing C, the middle sliding bearing B and the lower sliding bearing A are all provided with bearing bushes 4 .

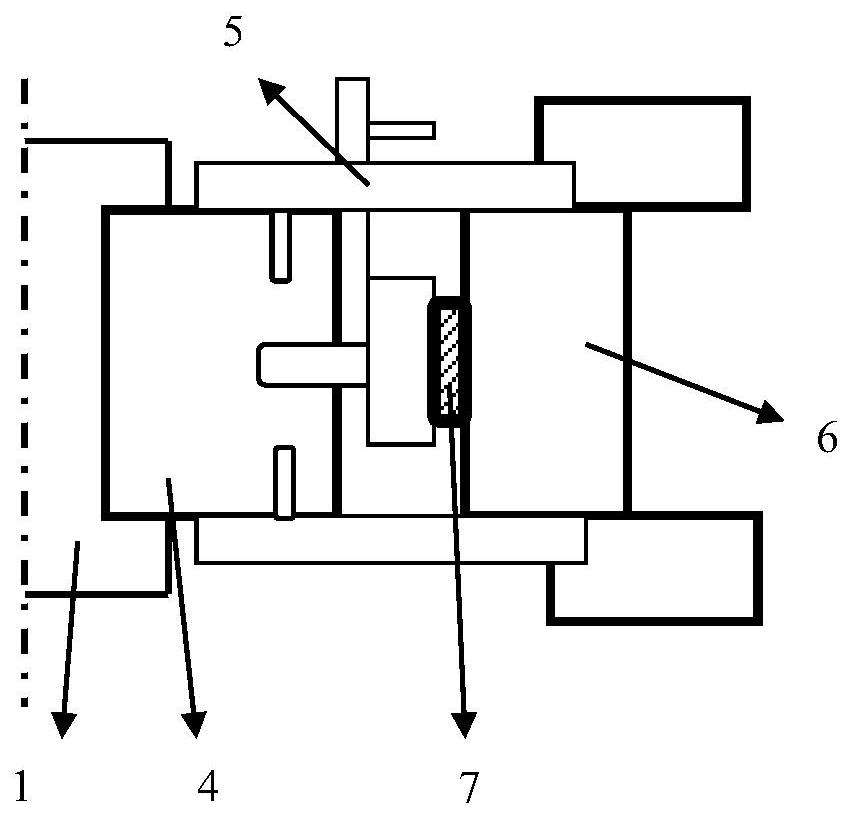

[0067] like figure 2 As shown, the upper sliding bearing C, the middle sliding bearing B and the lower sliding bearing A have the same structure, and all include the bearing bush 4, the bearing bush mounting bracket 5, the support frame 6 and the force sensor 7; the support frame 6 is fixedly install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com