Automatic tightening device for studs and nuts

An automatic tightening device and double-headed stud technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of heavy workload, different tightening degrees, and difficult to quantify the control and display of torque, and achieve Effect of improving tightening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

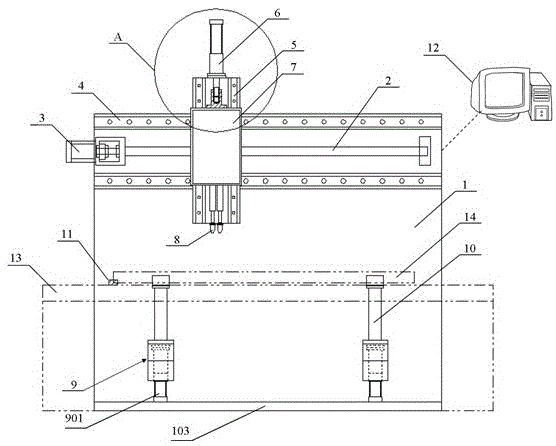

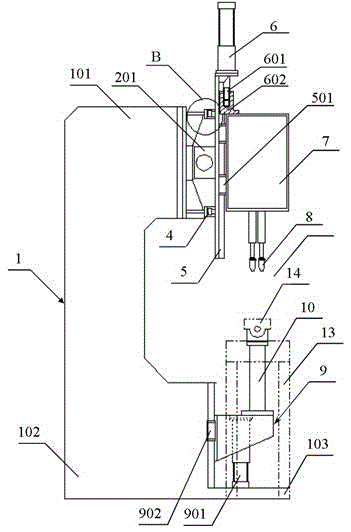

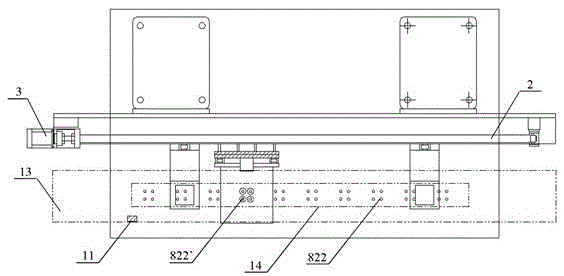

[0057]Below, the automatic tightening device of double-ended stud and nut of the present invention is described in detail with reference to accompanying drawing and embodiment:

[0058] Such as Figure 1~3 As shown, an automatic tightening device for double-ended studs and nuts includes a support 1 , which is arcuate and includes an arcuate upper part 101 , an arcuate lower part 102 and a platform 103 .

[0059] The bow-shaped upper part 101 is equipped with two parallel transverse guide rails 4 and a lead screw 2, the lead screw 2 is located between the two transverse guide rails 4, one end of the lead screw 2 is connected to the motor 3, and one side of the moving nut 201 is fixed to the back of the longitudinal guide rail 5 connected, the moving nut 201 meshes with the lead screw 2, and when the lead screw 2 rotates, the moving nut 201 drives the longitudinal guide rail 5 to move left and right along the transverse guide rail 4;

[0060] The bottom end of the bow-shaped lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com