Wind driven generator cable clamp

A technology of wind power generators and cable clamps, applied in the direction of electrical components, etc., can solve the problems of easy loosening of cable fastening and limited anti-loosening effect, and achieve the effects of prolonging the maintenance cycle, strong resistance to transmission, and not easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

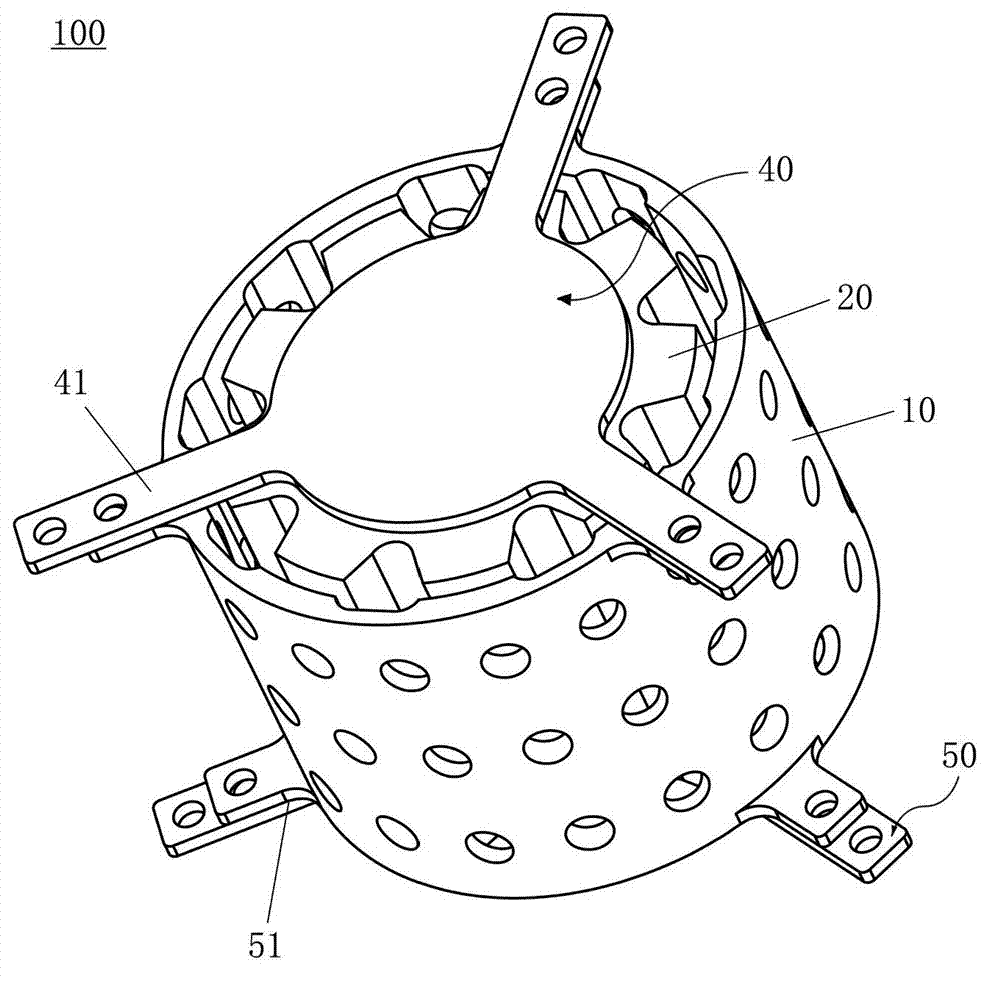

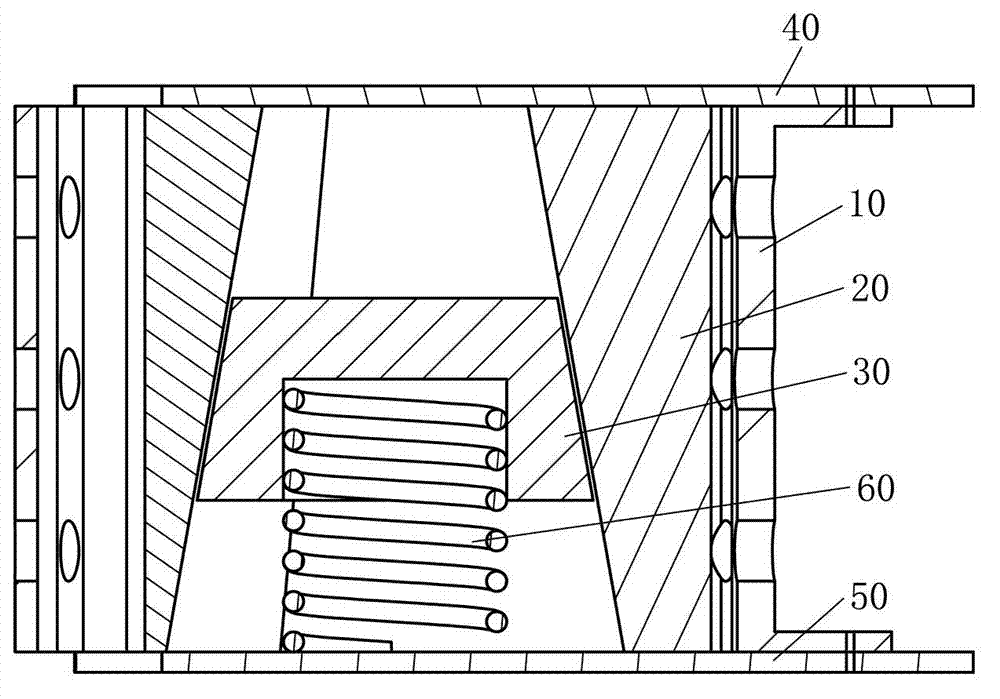

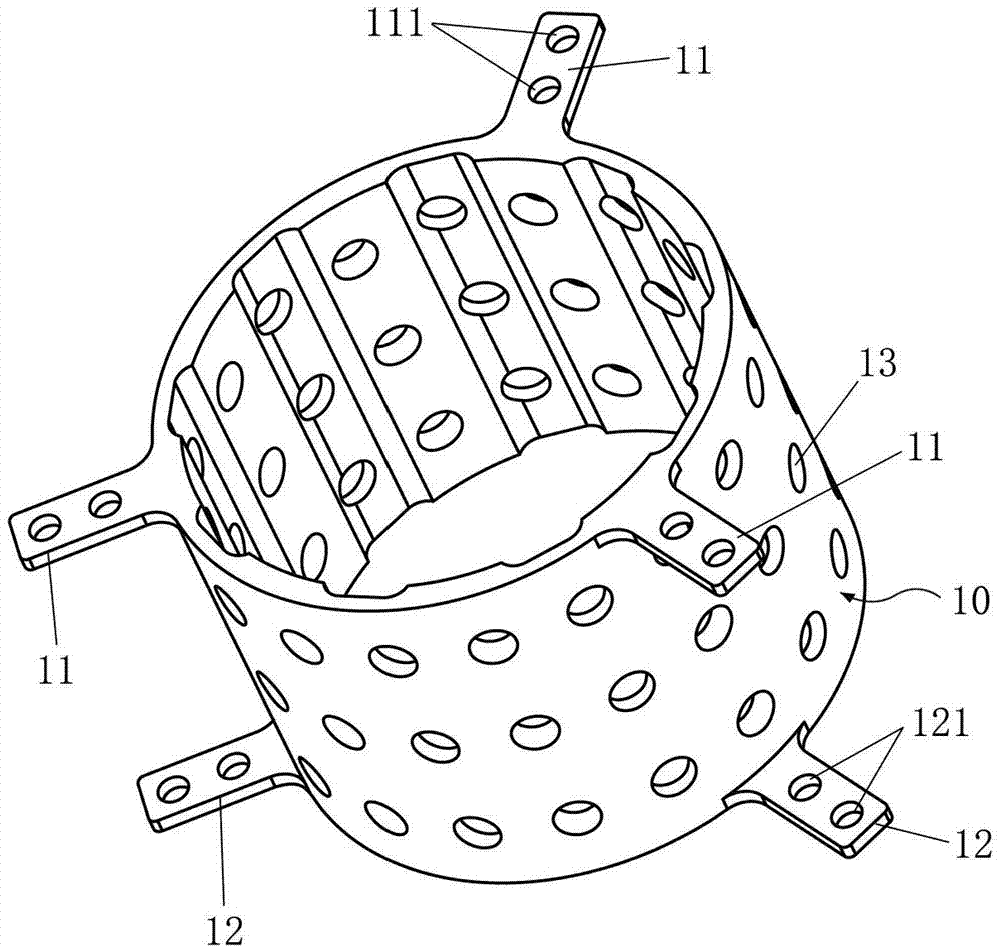

[0044] figure 1 is a perspective view showing a wind turbine cable clamp 100 according to an embodiment of the present invention; figure 2 is a sectional view showing the wind power generator cable clamp 100 according to the embodiment of the present invention.

[0045] Such as figure 1 with figure 2 As shown, the wind power generator cable clamp 100 according to an embodiment of the present invention includes: an outer ring body 10; an inner ring body 20, which is arranged inside the outer ring body 10 and forms a Accommodates cable 70 (see Figure 7 ) space; the inner cone 30 is arranged in the inner ring body 20, and tends to automatically squeeze the inner ring body 20 outward; the lower cover plate 50 is arranged at the bottom of the cable clamp 100 and is fixed with the outer ring body 10 The ground connection is used to support the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com