Cable winch for tool wagon

A tool trolley and cable reel technology, which is applied in the field of special cable winches for tool trolleys, can solve the problems of limited tools, the overall weight of cables is not too heavy, time-consuming and labor-intensive, etc., and achieve the effect of small weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

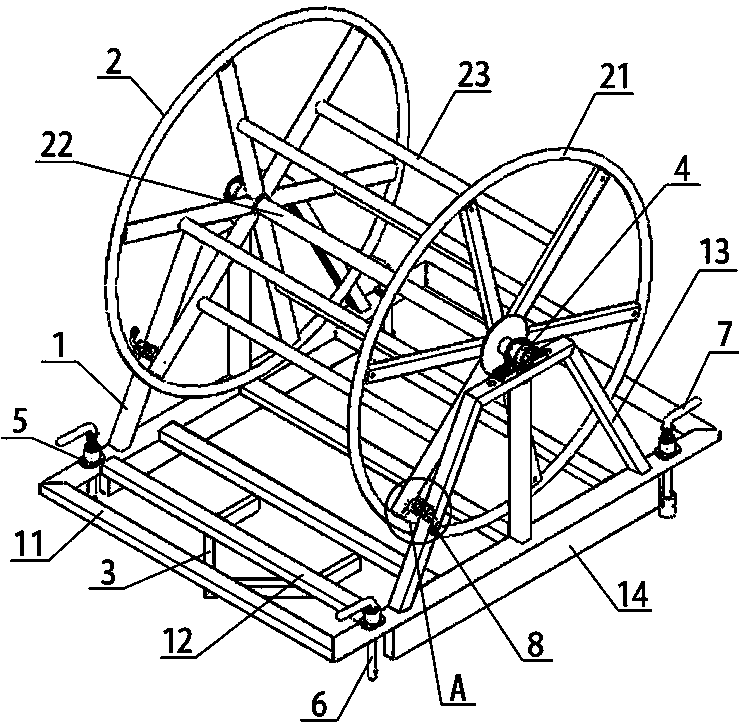

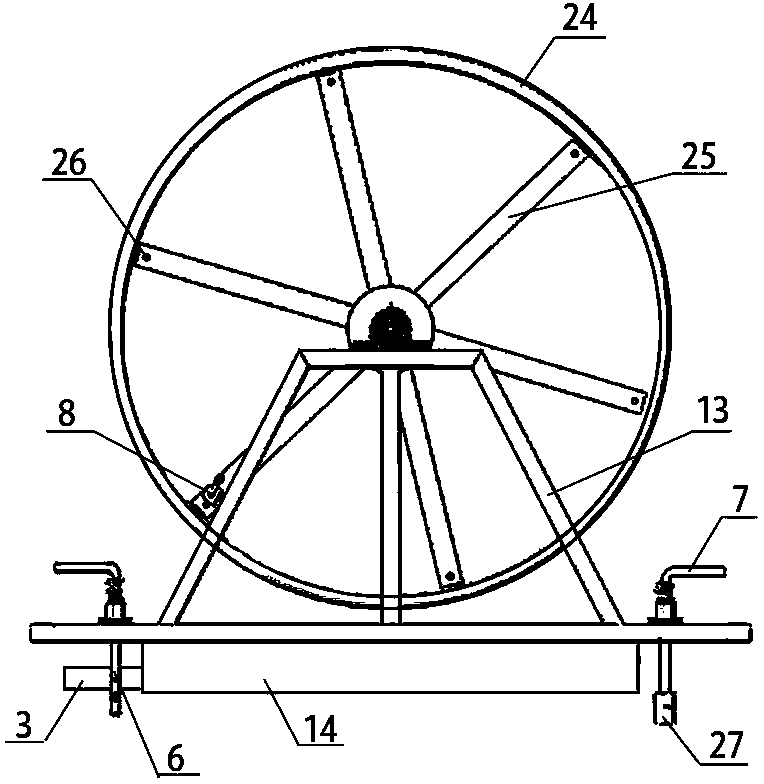

[0015] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, it includes a frame 1 made of steel structure and a cable reel 2; the cable reel 2 is erected on the upper end of the frame 1 through a bearing 4; the bottom of the frame 1 is provided with at least three threaded holes 5 ; The threaded hole 5 is provided with a bolt 6, the head of the bolt 6 extends vertically and forms a handle 7; the bottom surface of the frame is also provided with a guide device 3; the guide device 3 includes at least two main guides Strip 31; the two main guide strips 31 are welded vertically into one.

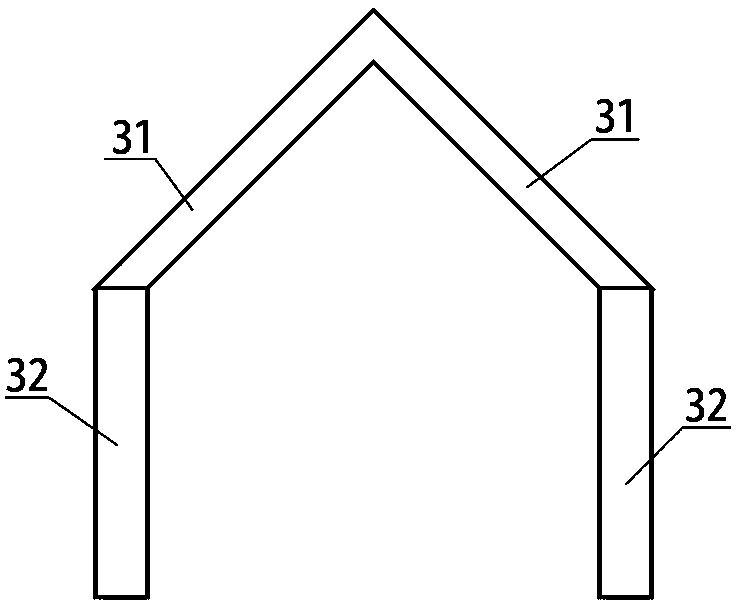

[0016] Such as image 3 , the respective ends of the two main guide strips 31 are provided with auxiliary guide strips 32, and the two auxiliary guide strips 32 are arranged parallel to each other; The guide bar forms a whole; the base plate of the tool cart is equipped with a guide device with the same structure as the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com