System and method for monitoring wireless sensor of coal cutter based on vibration energy harvesting

A vibration energy collection and monitoring system technology, which is applied in the fields of earth-moving drilling, cutting machinery, etc., to solve the difficulty of power supply and wiring, and solve the effect of periodic battery replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

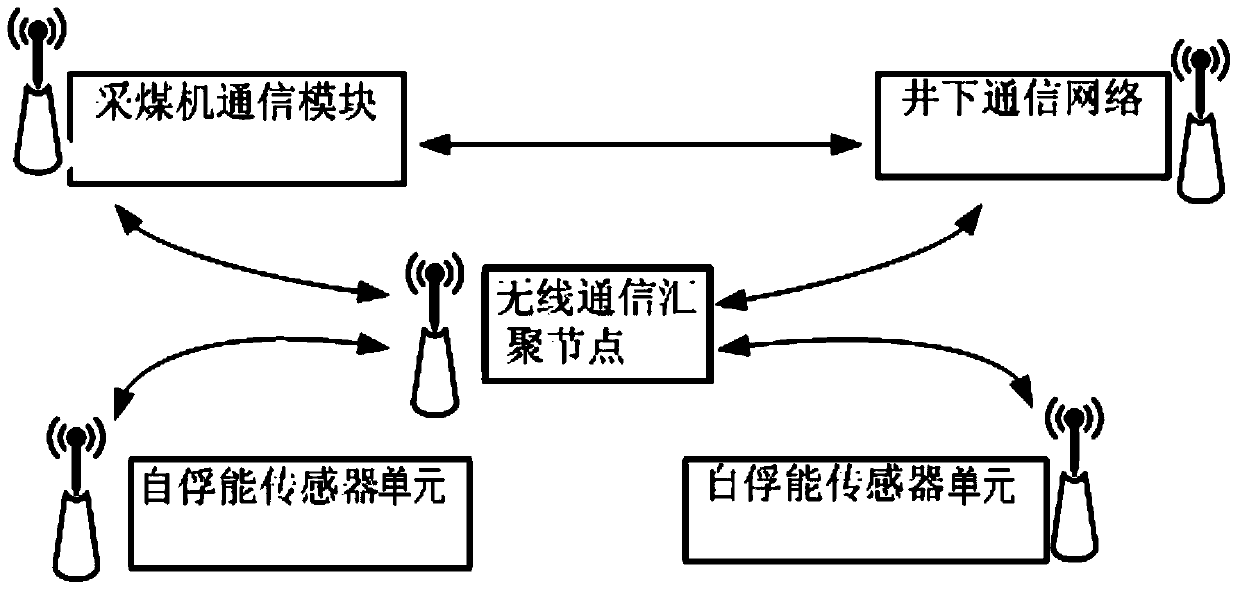

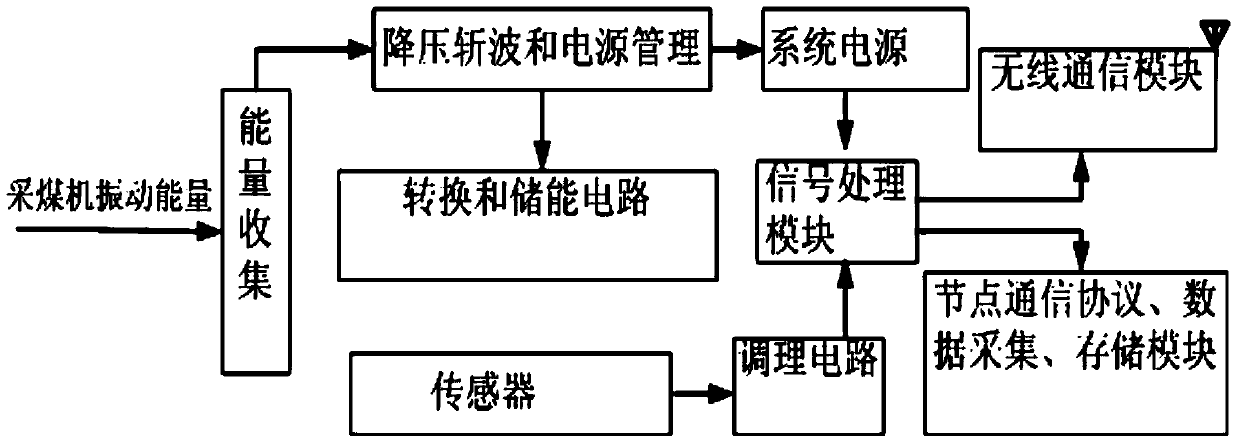

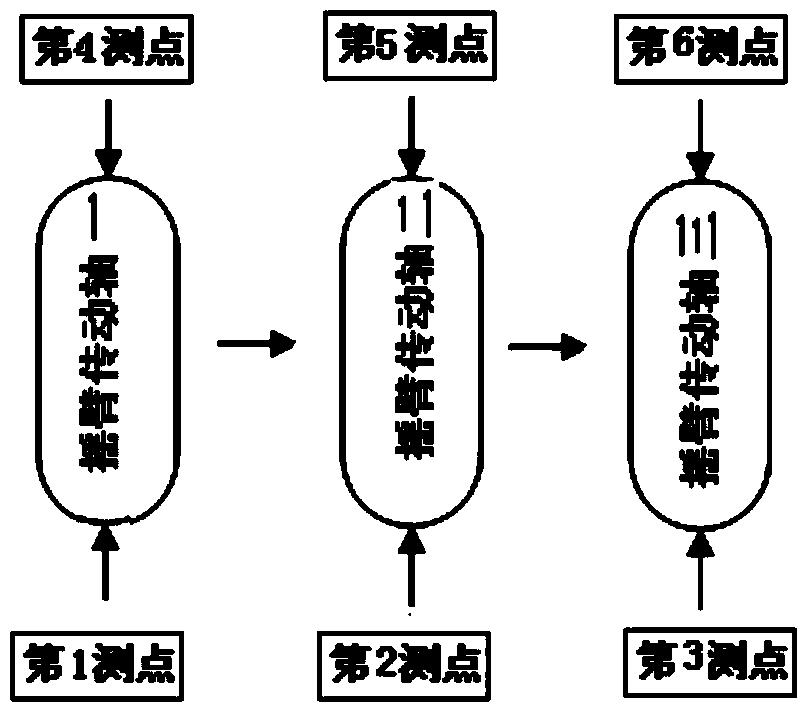

[0021] like figure 1 As shown, a wireless sensor monitoring system for a shearer based on vibration energy collection in the present invention includes N self-capturing sensor units, a wireless communication collection node, a shearer communication module, and an underground communication network. Among them, the self-capturing sensor unit such as figure 2 As shown, it includes an omnidirectional vibration energy harvesting device 3, a vibration sensor 2 and a conditioning circuit, an energy conversion and storage module, a system power supply, a signal processing module, a wireless transmission module, and a data storage module.

[0022] like Figure 4 As shown, except for the vibration sensor 2 in the self-capturing sensor unit, the omnidirectional vibration energy harvesting device 3 and all modules are installed inside an independent explosion-proof shell 1; the bottom of the shell is welded to the surface of the shearer parts, A circular antenna coil hole is left on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com