Diesel engine exhaust gas purification muffler

A diesel engine and exhaust gas purification technology, applied in engine components, machines/engines, mufflers, etc., can solve the problems of inability to transform diesel engines, poor decomposition effect, high oxygen content in exhaust gas, and achieve poor exhaust gas and good purification effect. , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

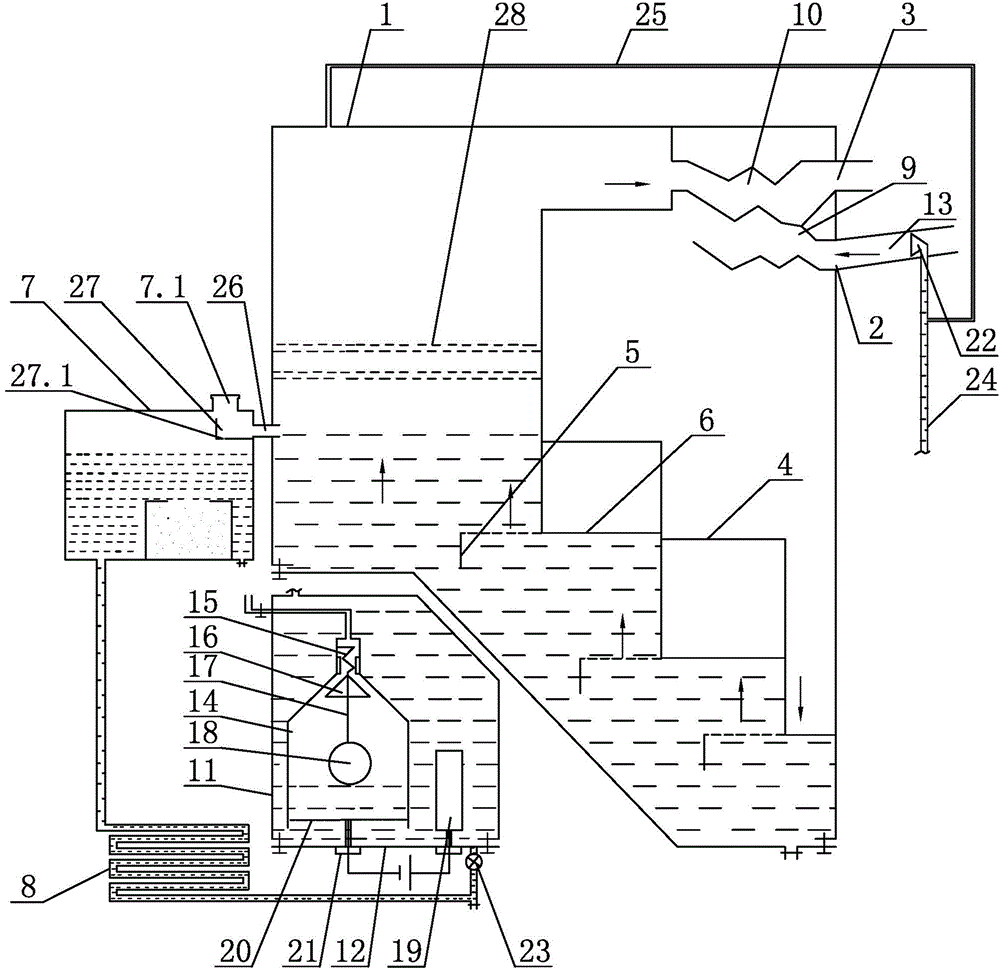

[0018] see figure 1 , a diesel engine exhaust gas purification muffler, comprising a purification muffler main body 1, an electrolytic tank with a water pump 23, a heat dissipation pipe 8, and a water storage tank 7, and the purification muffler main body 1 includes two air intake chambers and a purification chamber formed by partitions 4 The chamber body, wherein the purification chamber is provided with a combined structure of several gas baffles 5 and porous plates 6 to form a stepped purification channel above two levels; One end of air outlet pipe 10 is communicated with purification chamber, and the other end is communicated with air outlet 3, and one end of spiral air inlet pipe 9 is communicated with air inlet 2, and the other end communicates with air inlet chamber in the air inlet chamber, and air inlet 2 is externally connected with a Air intake pipe 13, straight air intake pipe 13 is provided with a conical nozzle 22 with an opening inward, the nozzle 22 is connect...

no. 2 example

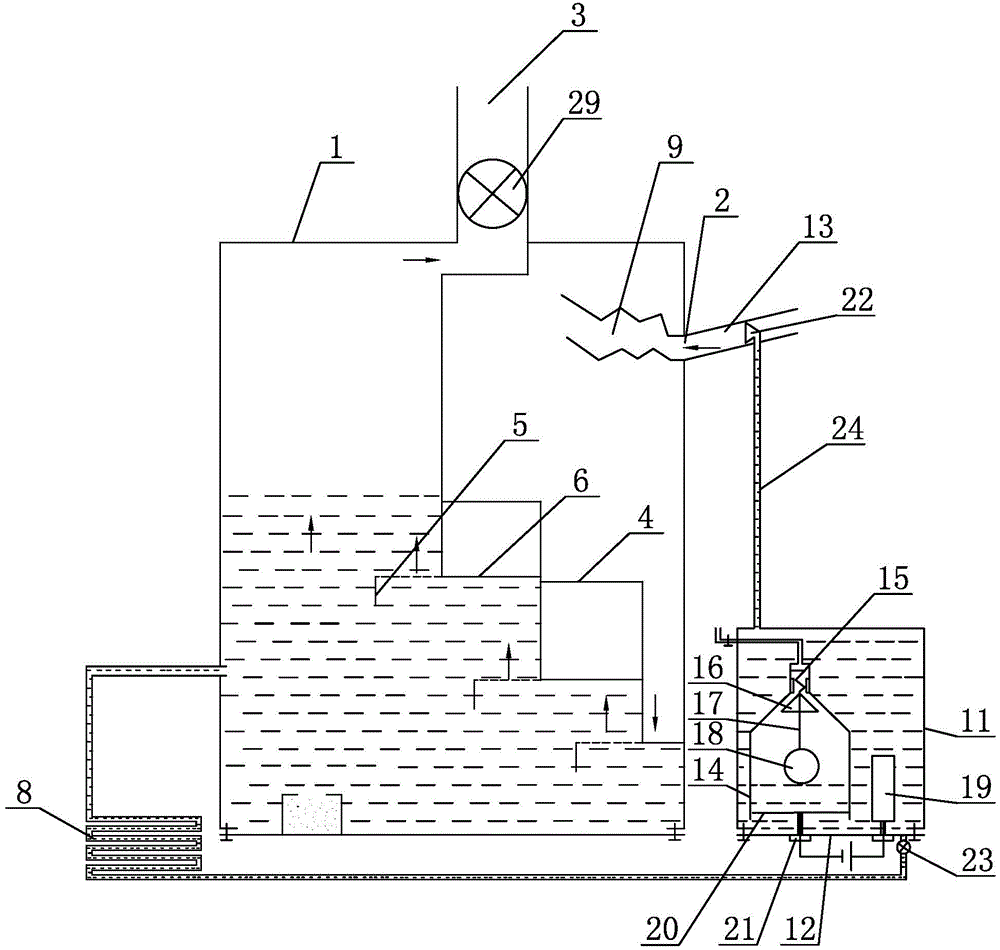

[0027] join figure 2 , this embodiment is used for wet desulfurization and nitrogen removal of industrial boilers. The difference from the first embodiment is that the spiral air outlet pipe 10 is changed to a blower 29, the water storage tank 7 is reduced, and the electrolytic tank is arranged at the air inlet. 2 below. Other parts not described are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com