Vacuum internal furnace

A technology for vacuum furnaces and furnaces, which is applied in furnaces, muffle furnaces, cooking furnaces, etc., can solve problems such as user hazards, troublesome production processes, and furnace furnace breakage, and achieve the goals of reducing potential dangers, facilitating production, and increasing strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

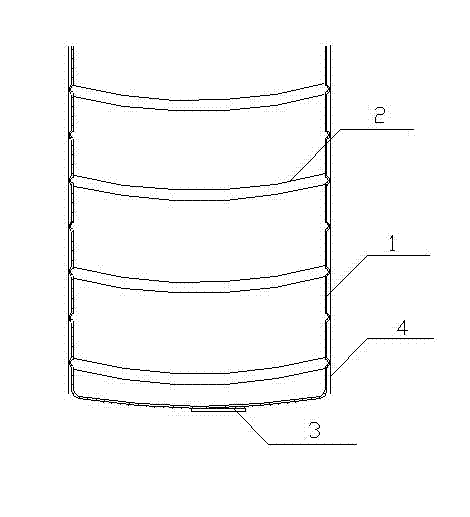

[0014] Such as figure 1 As shown, this embodiment provides a vacuum furnace, including a furnace body 1, a pressure sealing head 3 arranged at the bottom of the furnace body 1, a flange part 4 surrounding the outside of the furnace body 1, and a A plurality of reinforcing ribs 2 between the furnace body 1 and the flange part 4, the furnace body 1 is welded after being rounded and corrugated, and the reinforcing ribs 2 are grooved and marked with "C" "The font surrounds the front and back of the furnace body 1. The number of reinforcing ribs 2 is 4~6, and each of the reinforcing ribs 2 is in the shape of an arc groove and arranged horizontally around the outer periph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com