Independent five-degree-of-freedom ultra-precise material in-situ test microscopic observation platform

A technology of in-situ testing and degrees of freedom, applied in the field of precision scientific microscopic observation instruments, can solve problems such as limited cavity space, difficulty in achieving specimens, and synchronous tracking, achieving good tracking effect, strong practicability, and compact size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

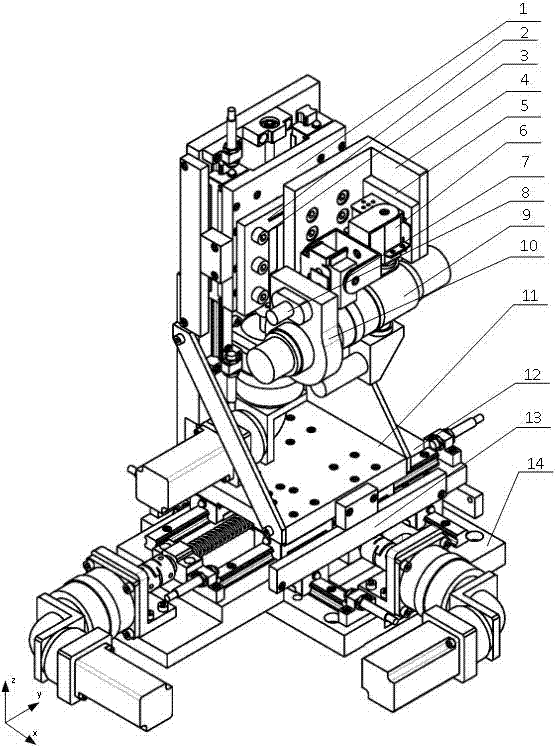

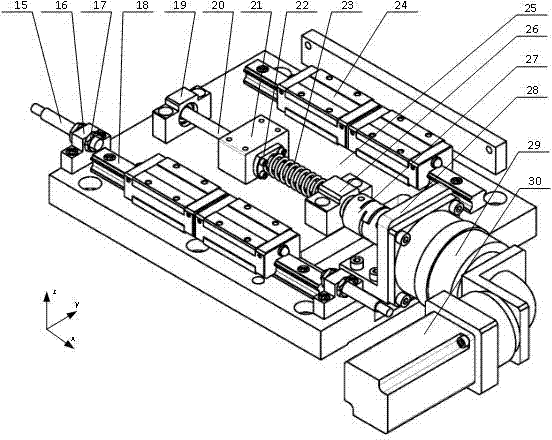

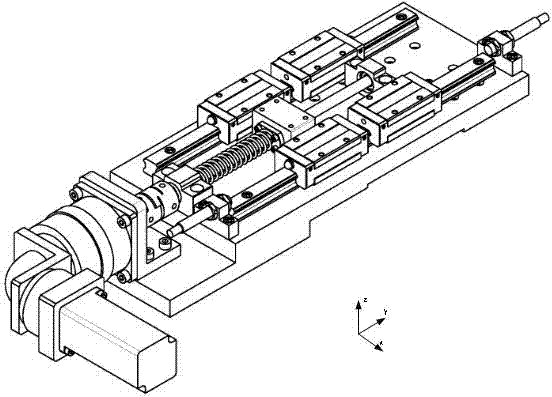

[0028] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0029] see Figure 1 to Figure 7 As shown, the independent five-degree-of-freedom ultra-precision material in-situ testing microscopic observation table of the present invention is mainly composed of X, Y, and Z-axis moving assemblies 14, 12, 11, X, and Z-axis rotating assemblies 7, 6, and X, Y-Z Axis flexible hinge type ultra-precision follower components 5, 2 and super depth-of-field observation lens 9 are composed.

[0030] The Y-axis moving assembly 12 is installed on the X-axis moving assembly 14, and the Z-axis moving assembly 11 is installed on the Y-axis moving assembly 12; the following assembly base plate 1 is installed on the Z-axis moving assembly 11, and the Y-Z axis following assembly 2 is installed on the bottom plate 1 of the follower assembly through the hexagon socket head cap screw 3, and the X...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com