Data processing method of multi-fiber bragg grating reinforcing steel corrosion sensor system

A steel bar corrosion and data processing technology, applied in the fields of weather resistance/light resistance/corrosion resistance, instruments, scientific instruments, etc., can solve difficult and complex data processing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

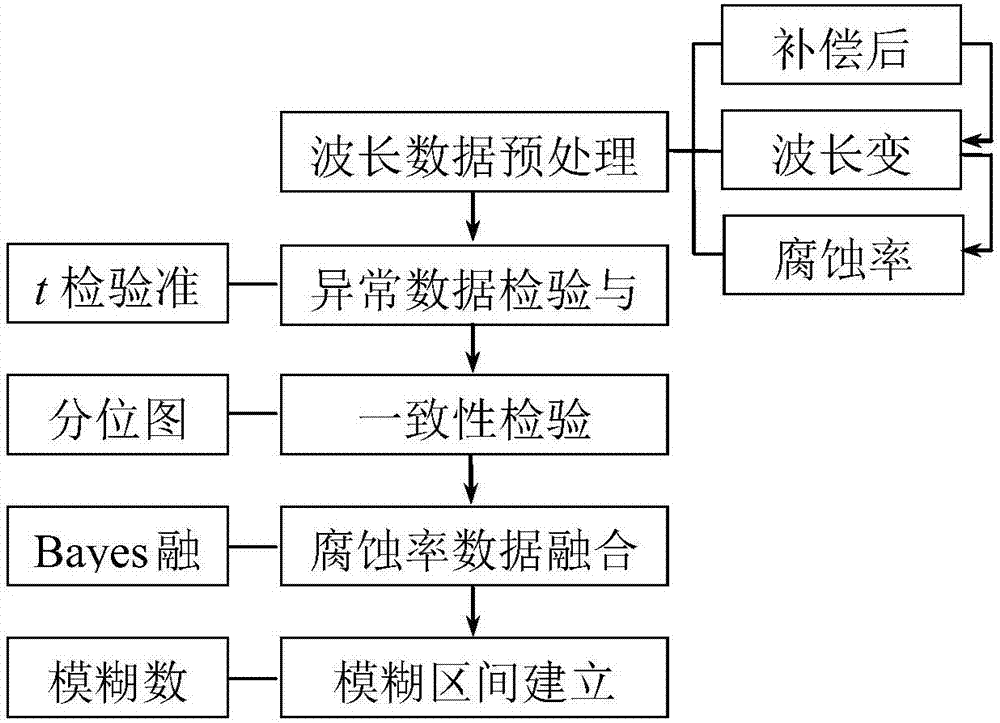

Method used

Image

Examples

Embodiment Construction

[0054] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

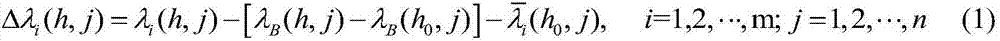

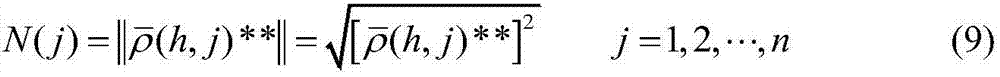

[0055] A reinforced concrete member is equipped with 10 sensor groups, each corrosion sensor reads 6 times, and each compensation sensor reads 1 time. The average initial wavelength of the corrosion sensor, the initial wavelength of the compensation sensor, and the wavelength readings of a certain acquisition are shown in Table 1. The wavelength readings collected by the corrosion sensor are shown in Table 2. The corrosion rate of the sensor group ρ=2.26916(Δλ) 2 +0.64302Δλ+0.23229, where Δλ is the wavelength change. The significance level of the t-test for the corrosion rate obtained from the sensor group is 0.05, the coefficient γ for the consistency test of the mean value of the corrosion rate is 1.0, and the threshold value used when establishing the fuzzy interval of the corrosion rate is 0.5. According to the data in Table 1 and Table 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com