A method for calibrating motor position disturbance force

A calibration method and motor position technology, applied in the direction of electric speed/acceleration control, etc., can solve the problems of servo accuracy reduction, error, and different motion trends, etc., to achieve improved control accuracy, servo accuracy, and fewer iterations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0031] The force that the linear motor receives during the movement includes motor driving force, cable force, magnetic field wave power, stiffness damping force, etc., among which cable force, magnetic field wave power, and stiffness damping force are all related to position and are collectively referred to herein as Position interference force.

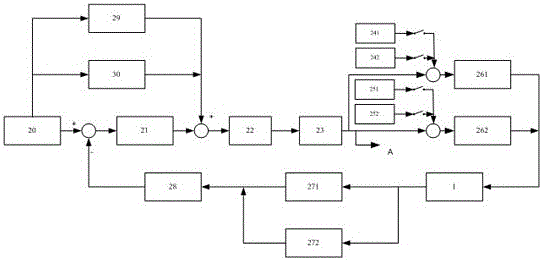

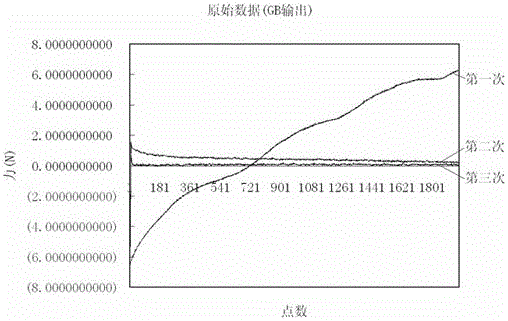

[0032] Such as image 3 As shown in the schematic diagram of the control loop of the positioning platform, the Set Point Generator 20 (SPG, Set Point Generator) is used for trajectory planning to generate sequence values of acceleration, velocity and displacement, and the generated velocity feedforward coefficient 29 and acceleration feedforward coefficient 30 is added to the output of the proportional-integral-derivative controller 21 through feedforward, and acts together on the gain scheduler 22 (GS, Gain Scheduling). The output of the gain scheduler 22 acts on the gain balancer 23 (GB, Gain Balance). The gain scheduler 22 is used...

no. 2 example

[0050] Refer to the test flowchart of the position interference force meter in this embodiment Figure 8 As shown, the difference from the first embodiment is: (1) Step 1 of the embodiment is omitted, that is, there is no need to clear the original position interference force table; (2) In step 8, the boundary point The values are only calculated and not compensated.

no. 3 example

[0052] The difference between this embodiment and the first embodiment is: (1) In step 2, the start and end positions of the movement are both within the design stroke; (2) the following steps are added between step 6 and step 7, according to The position interference force table in the uniform speed section uses data fitting to calculate the position interference force table in the acceleration and deceleration section. Such as Picture 9 As shown, the fitting is carried out according to the data of the uniform speed section (represented by the circle in the figure) (represented by the solid line in the figure), and it extends to the acceleration and deceleration section according to the trend of the fitted graph. The point represented by the five-pointed star in the figure is based on the fitting graph Calculated by the trend.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com