System based on array-type flexible electric eddy sensor for monitoring gap between spherical layers

An eddy current sensor and flexible array technology, applied in the field of data processing, can solve problems such as slow real-time monitoring, achieve effective solutions, improve anti-interference ability, and solve data processing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

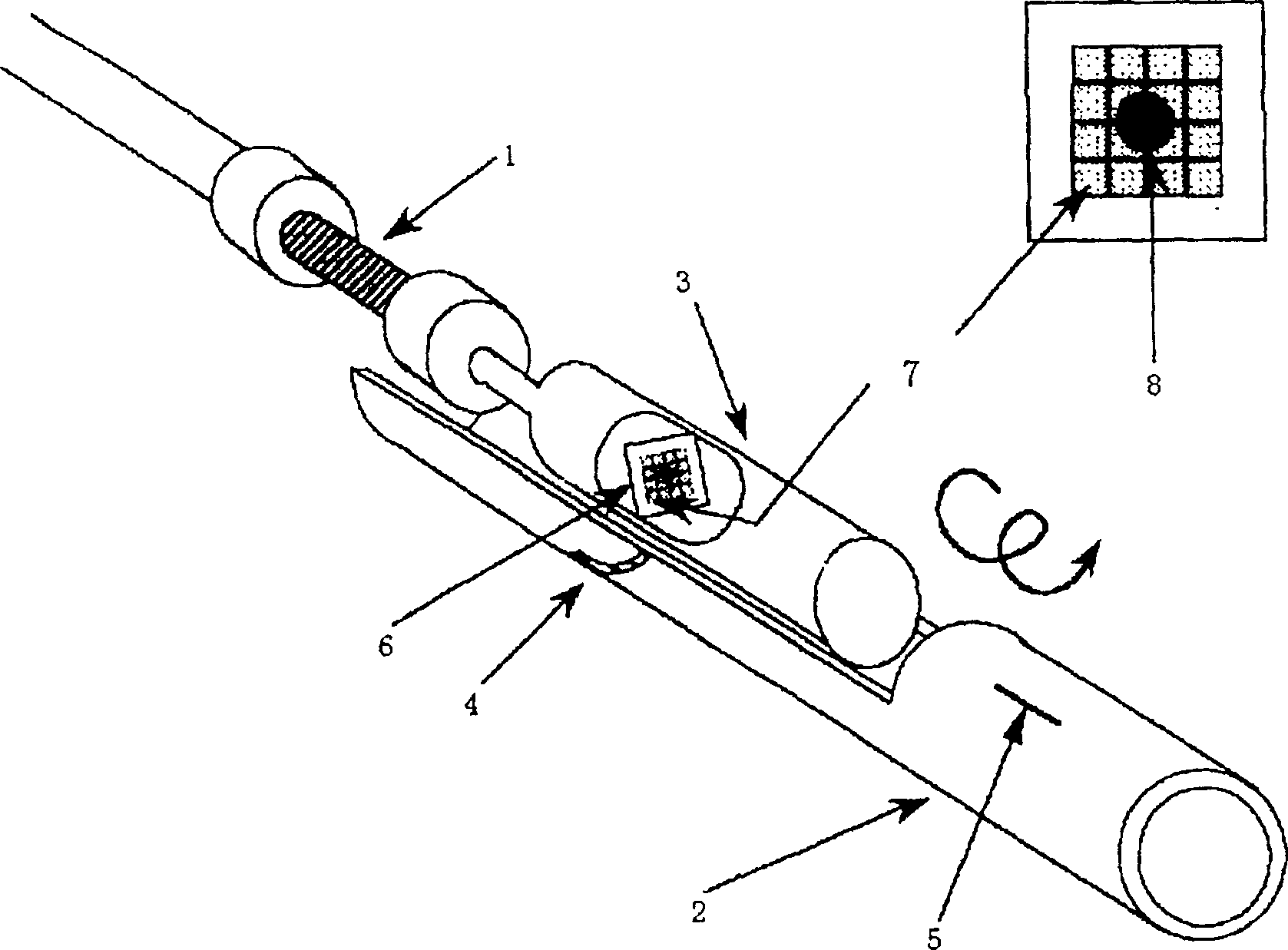

[0028] A spherical interlayer gap monitoring system based on a flexible array type eddy current sensor designed by the present invention is described in detail in conjunction with the drawings and embodiments as follows:

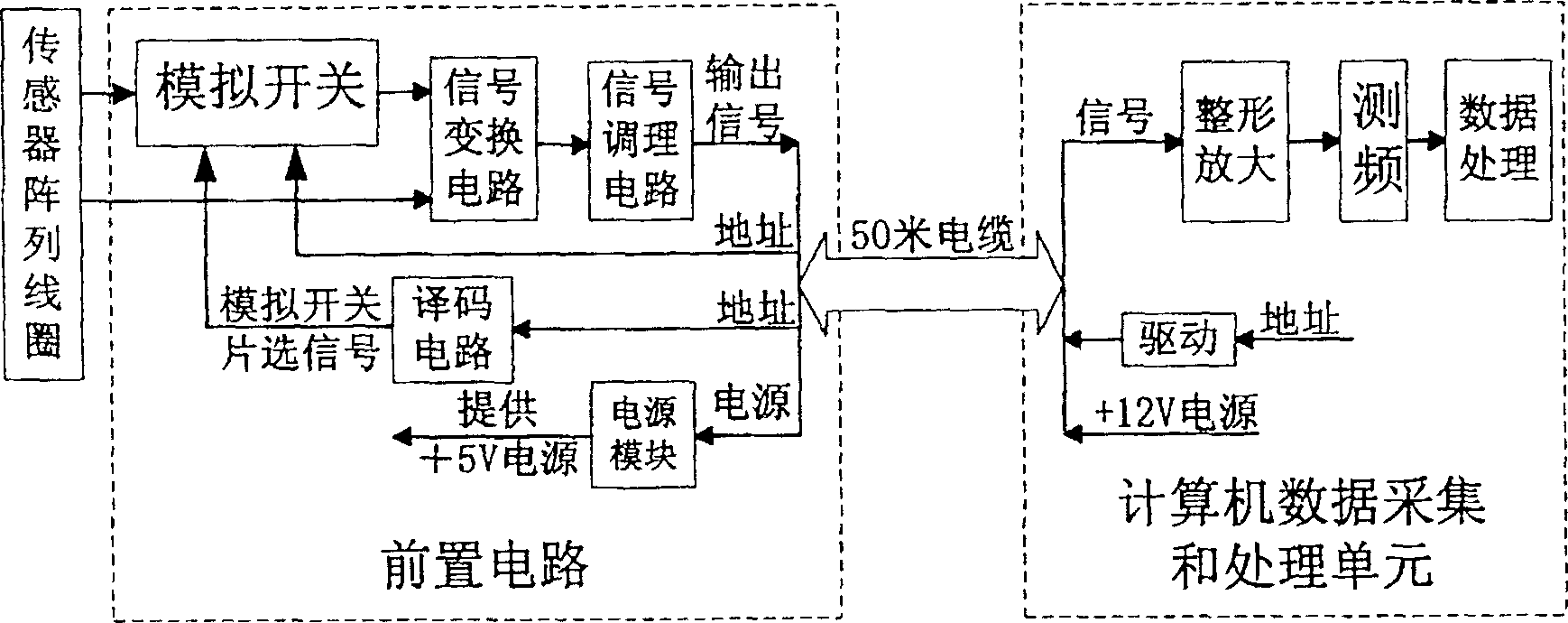

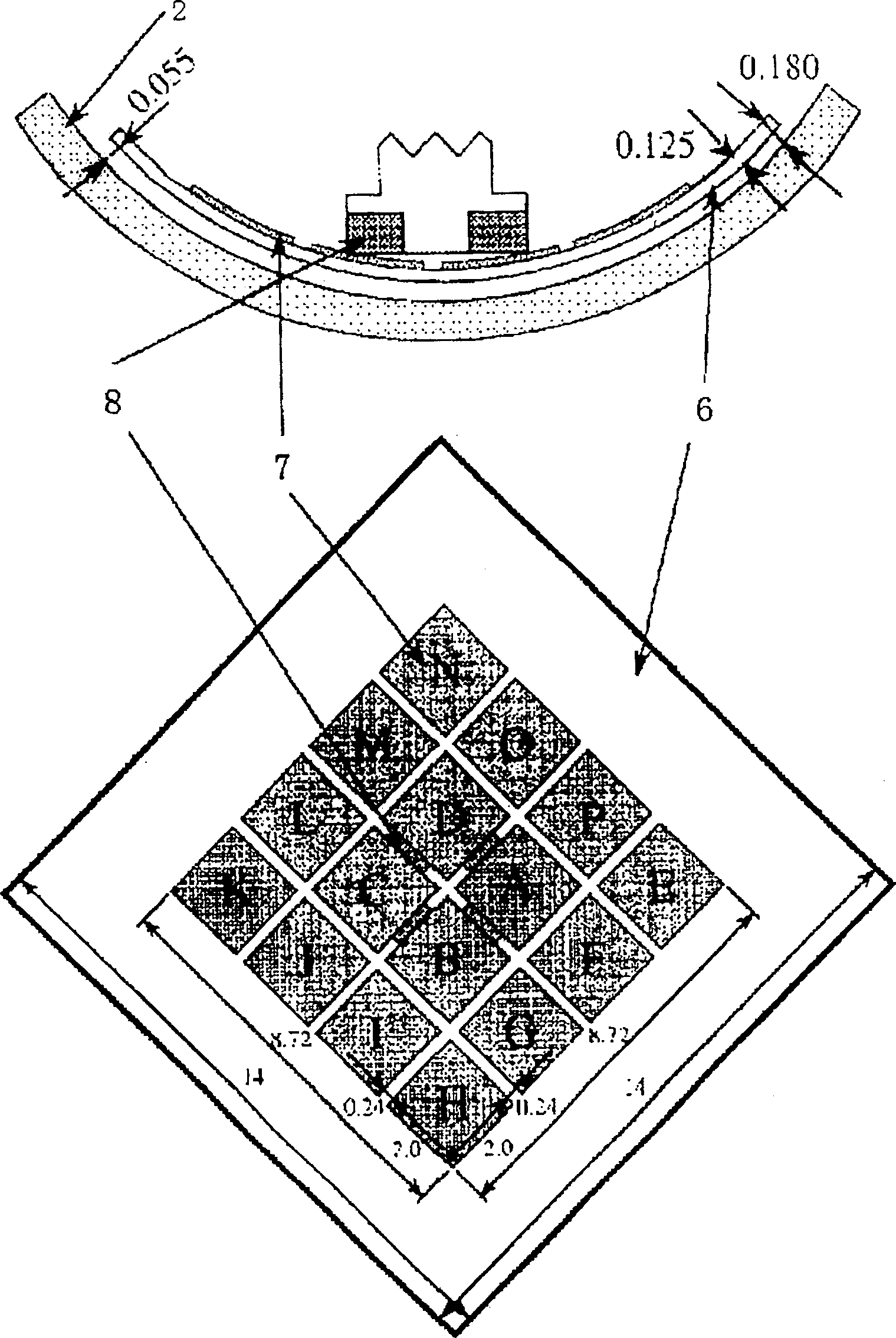

[0029] The composition of the spherical interlayer gap monitoring system based on the flexible array type eddy current sensor of the present invention is as follows: image 3 As shown, it is mainly composed of three parts: sensor probe, front circuit, computer data acquisition and processing unit. Among them, the sensor probe includes a sensitive coil array made on a flexible substrate material, and each coil signal line and its ground line are connected to form a common A densely packed long cable composed of ground wires; the front circuit includes a multi-channel analog gate circuit composed of a decoding circuit and an analog switch, a sensor signal conversion and conditioning circuit connected to it, and a power supply module that provides operating voltag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com