Indoor load test device for post-grouting of pile ends

A load test and post-grouting technology, which is applied in the preparation of test samples and the use of stable tension/pressure to test the strength of materials, etc., to achieve the effects of ensuring stability and firmness, convenient installation and operation, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

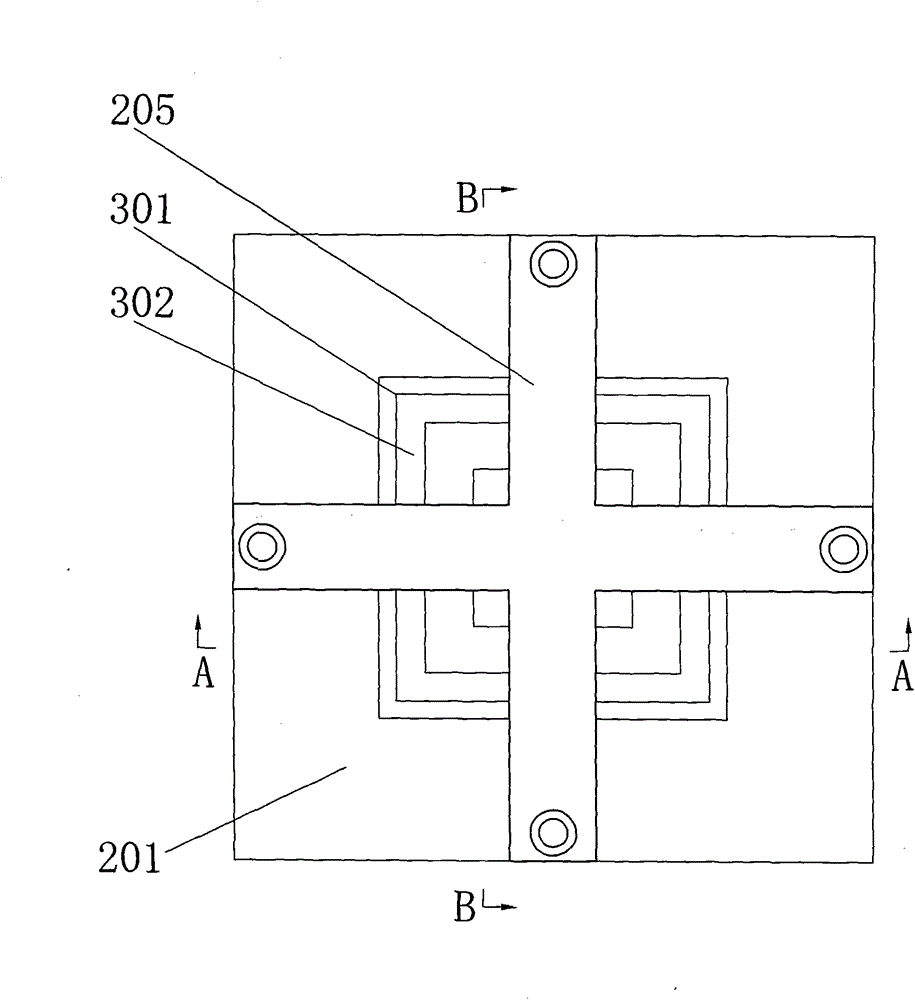

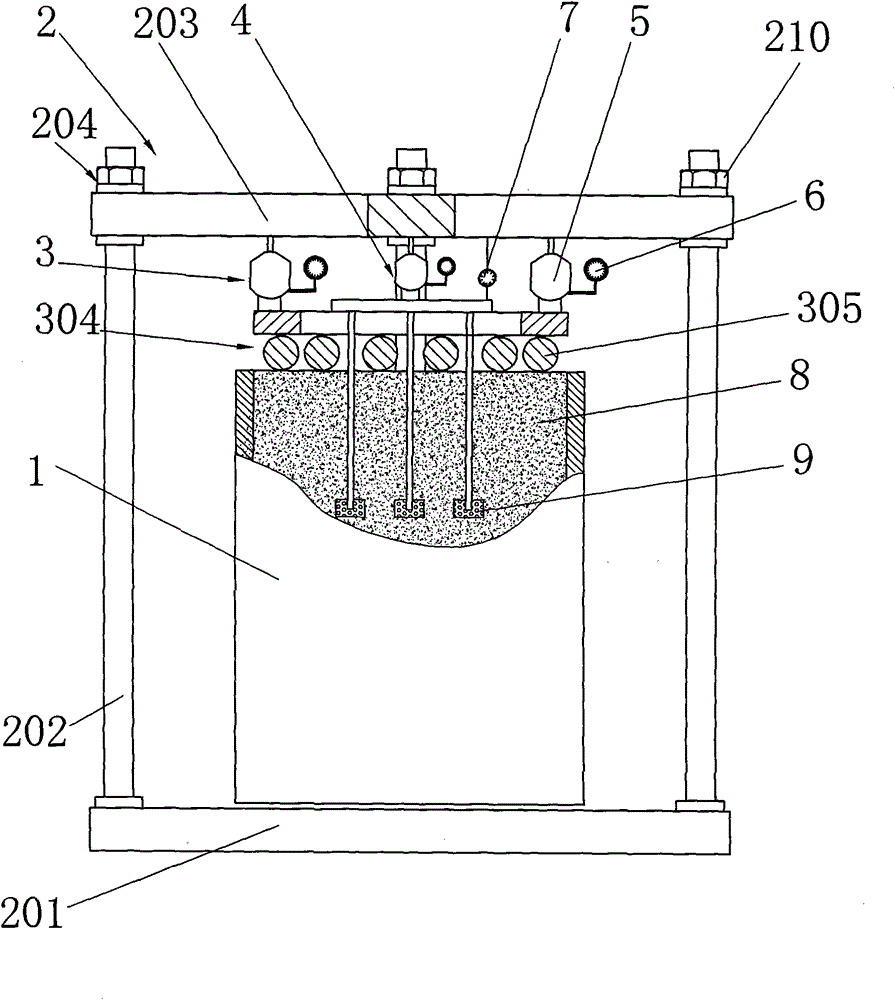

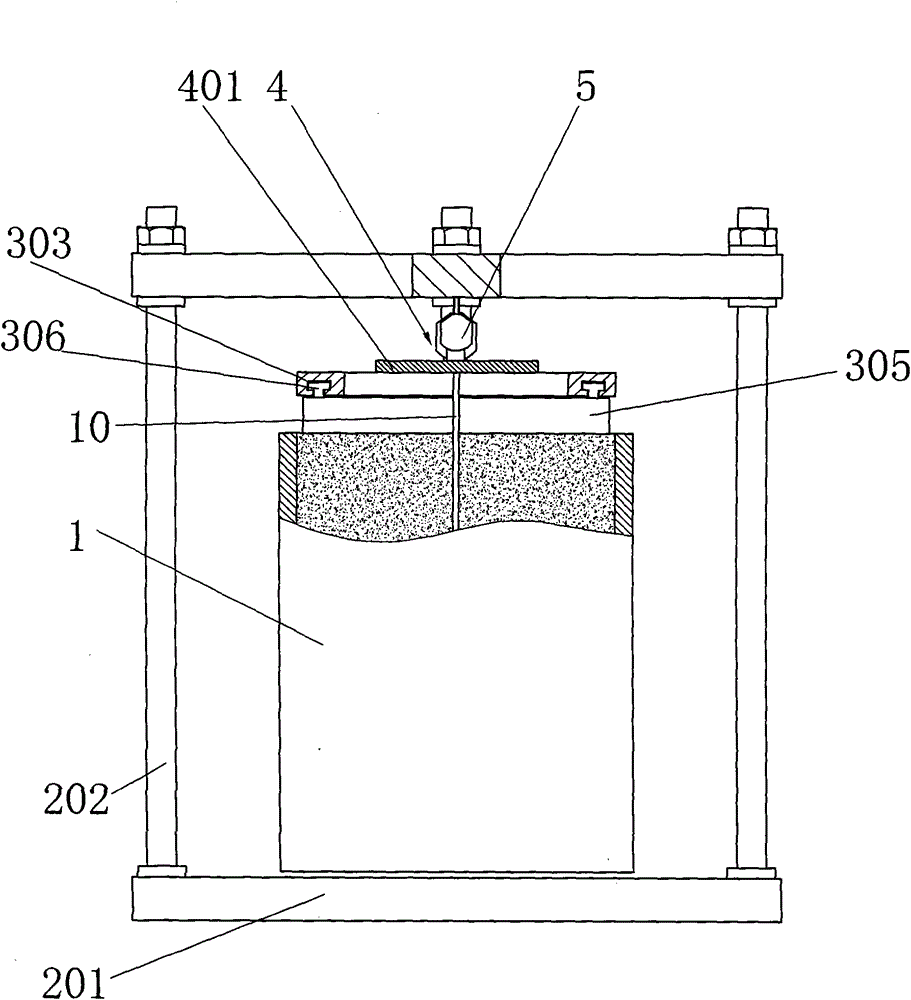

[0056] refer to Figure 1 to Figure 4 , the load test device in the post grouting chamber of the pile end includes a load box 1, a counter force device 2, a soil pressurization device 3, and a pile body pressurization device 4.

[0057] The reaction force device 2 in the present invention includes a chassis 201 , four connecting rods 202 , a reaction force frame 203 and an adjustment structure 204 . The reaction force frame 203 includes two reaction force rods 205 arranged in a cross shape and fixed in the middle. The reaction force rods 205 have two parallel upper and lower planes, and two ends of each reaction force rod 205 are respectively provided with a through The through holes 206 on the upper and lower planes. The lower ends of the four connecting rods 202 are provided with external threads 209, and are fixedly connected to the chassis 201 by nuts 210; the upper ends of the four connecting rods 202 are connected with the reaction force frame 203 through the adjustment...

Embodiment 2

[0067] refer to Figure 5 with Image 6 As shown, the difference between this embodiment and Embodiment 1 is that the adjusting bolt 207 includes a connecting head 20a and a positioning ring 20h, the connecting head 20a has a ring-shaped connecting portion 20c and a clamping portion 20e, and the internal threaded hole 208 runs through The connecting part 20c and the clamping part 20e; the clamping part 20e is located at one end of the connecting part 20c and protrudes radially outward, and the positioning ring 20h is clamped at the other end of the connecting part 20c. Specifically: the outer surface of the annular connecting portion 20c is provided with two guide grooves 20j along the axial direction and two annular grooves 20k extending along the same circumferential direction of the connecting portion 20c, one guide groove 20j communicates with one annular groove 20k The inside of the positioning ring 20h has two positioning blocks 20i protruding inward. When the positioni...

Embodiment 3

[0069] The test method of the post-grouting indoor load test device at the pile end is an indoor pile static load simulation test. This test method includes the following steps:

[0070] The first step is to make the pile body 10 . Make the pile body 10 forming mold first: take one or more hollow round steel pipes whose length is longer than the pile body 10, cut the round steel pipes into two semi-arc or three arc-shaped arc petals along the axis direction; buckle the arc petals into A round steel pipe, and the two ends and the middle of the round steel pipe are fastened by ring screws; one end of the round steel pipe is sealed, and a layer of cotton gauze is placed inside the end, and the other end is an open end. Make the pile body 10 reinforcement structure: select the thin steel bar to make it into a reinforcement cage that can be put into the round steel pipe; place the round steel pipe vertically with the open end up; put the reinforcement cage into the round steel pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com