Tiny sample stress corrosion experimental device and tiny sample stress corrosion experimental method

A technology of stress corrosion and experimental equipment, applied in the direction of testing wear resistance, etc., can solve the problem of no micro-sample stress corrosion experimental system, and achieve the effect of preventing major economic losses and casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

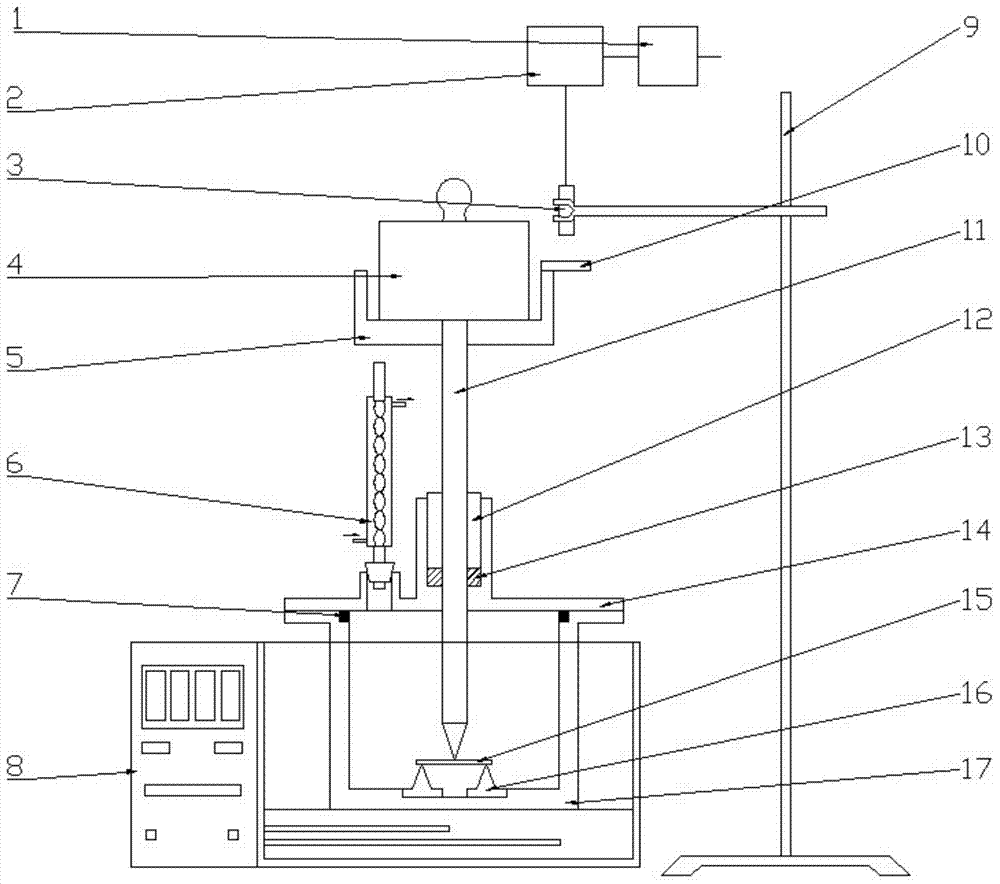

[0031] The preferred embodiments are given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

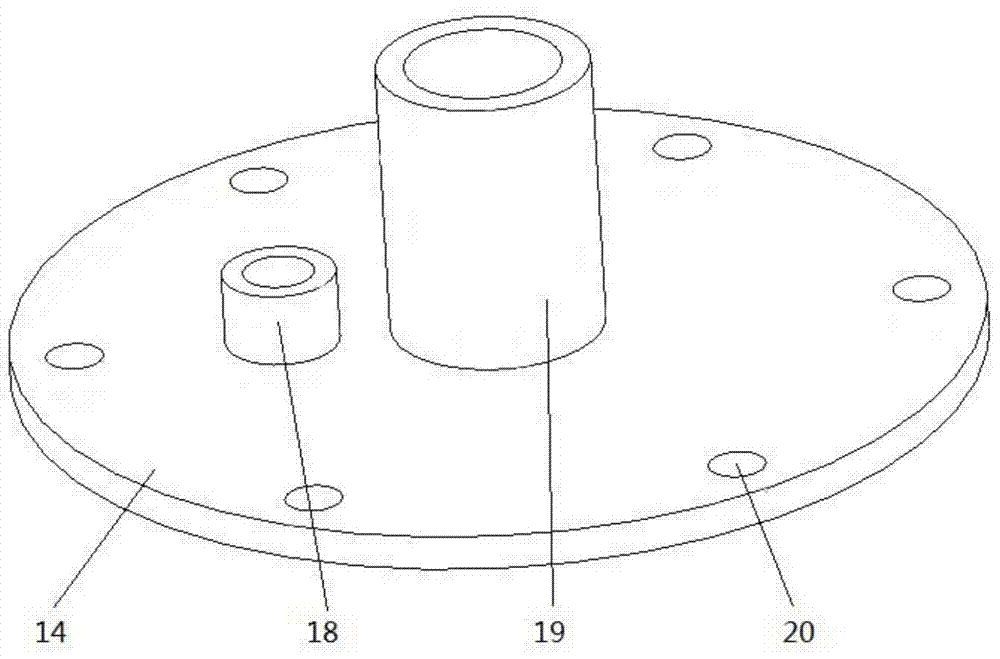

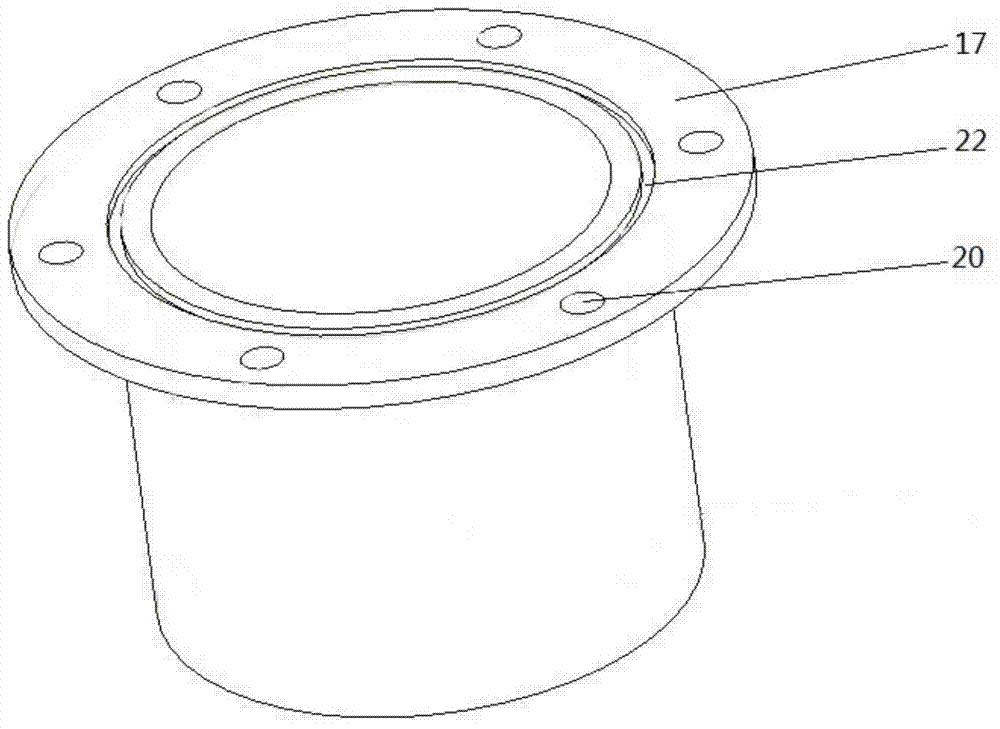

[0032] Such as Figure 1-4 As shown, this embodiment includes a computer 1, a magnetic induction sensor 2, a magnetic induction joint 3, a weight 4, a loading platform 5, a reflux condenser 6, a sealing ring 7, a constant temperature water bath 8, an iron stand 9, an induction plate 10, and a force rod 11. Positioning sleeve 12, sealing block 13, groove cover 14, sample 15, support 16, corrosion groove 17, reflux condensation interface 18, protrusion 19, bolt hole 20, support fixing groove 21, sealing groove 22, bolt 23, nut 24.

[0033] Such as figure 1 with 2 As shown, the slot cover 14 of this embodiment includes a protruding portion 19 , and the stress loading mechanism includes a loading platform 5 and a force applying rod 11 connected under the loading platform 5 , and the force applying rod 11 penet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com