Method and device for controlling MFT (Main Fuel Trip)

A technology for controlling equipment and equipment, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problem of boiler full fuel loss MFT main protection action, etc., to ensure normal production operations, reliable control logic, and avoid errors The effect of protective action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

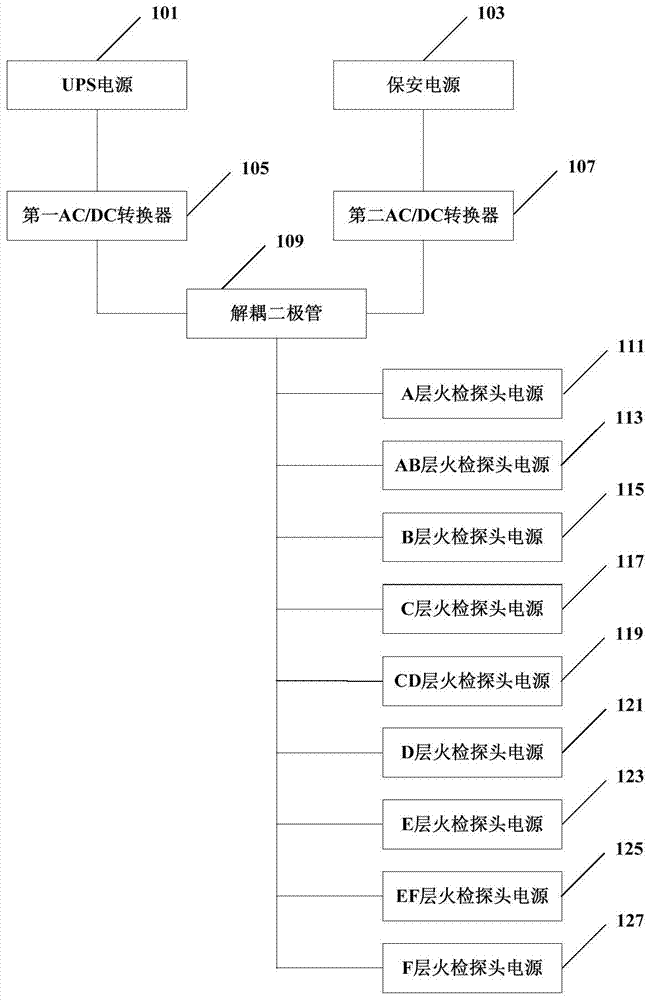

[0047] During the production operation of the power plant, the power supply may be abnormal, which will cause the flame detection probes to not work normally, and if the detection results of all the flame detection probes are abnormal, it may lead to the loss of all flames. MFT has a protection action, which has a negative impact on the entire production operation.

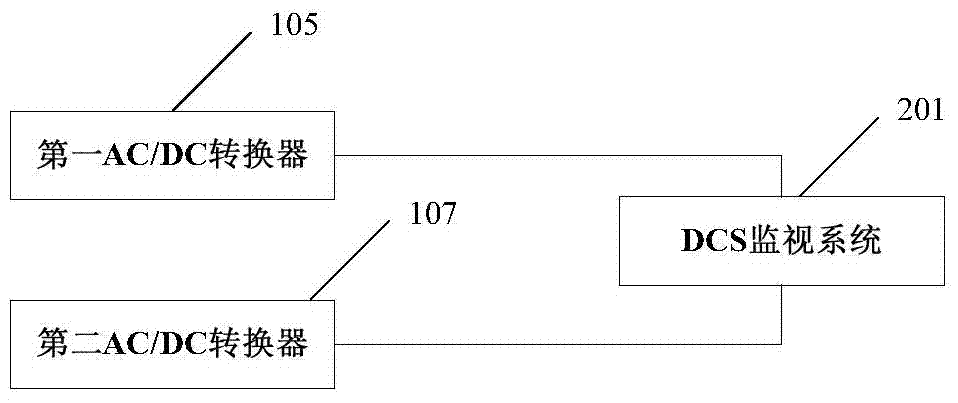

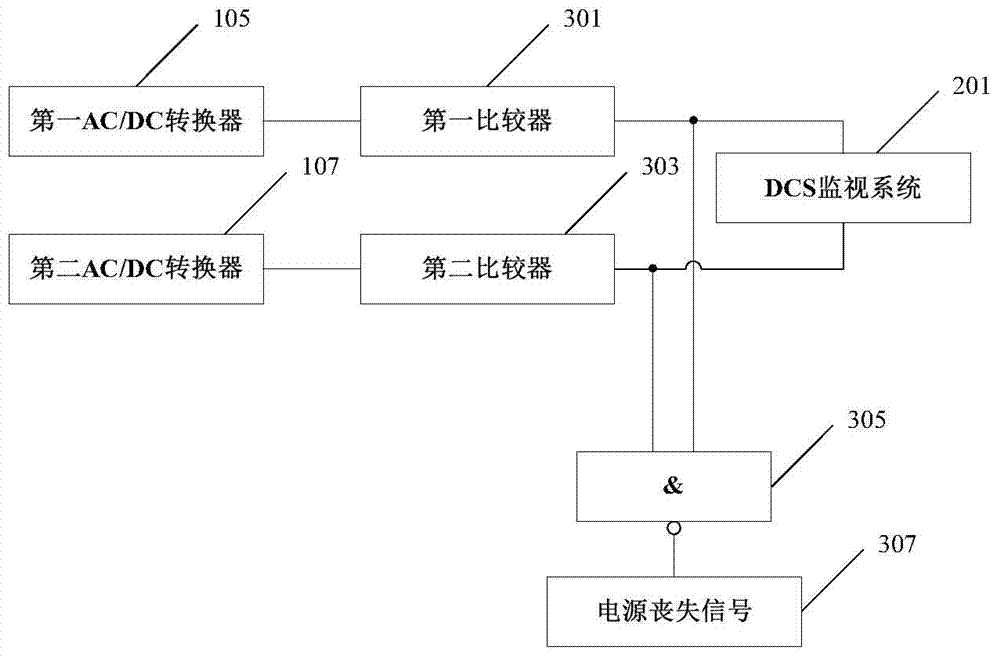

[0048] In order to solve this problem, the present invention provides an MFT control device, which includes an OR gate, the combustion flame loss signal and the power supply loss signal are used as the input signals of the OR gate, and the output terminal of the OR gate is connected to the boiler fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com