A Method of Printed Circuit Board Defect Detection Based on Regularized Parameters

A printed circuit board, defect detection technology, applied in the direction of measuring devices, image data processing, instruments, etc., can solve the problems of long maintenance cycle, low detection efficiency, high price, etc., and achieve the effect of high-speed and high-reliability requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

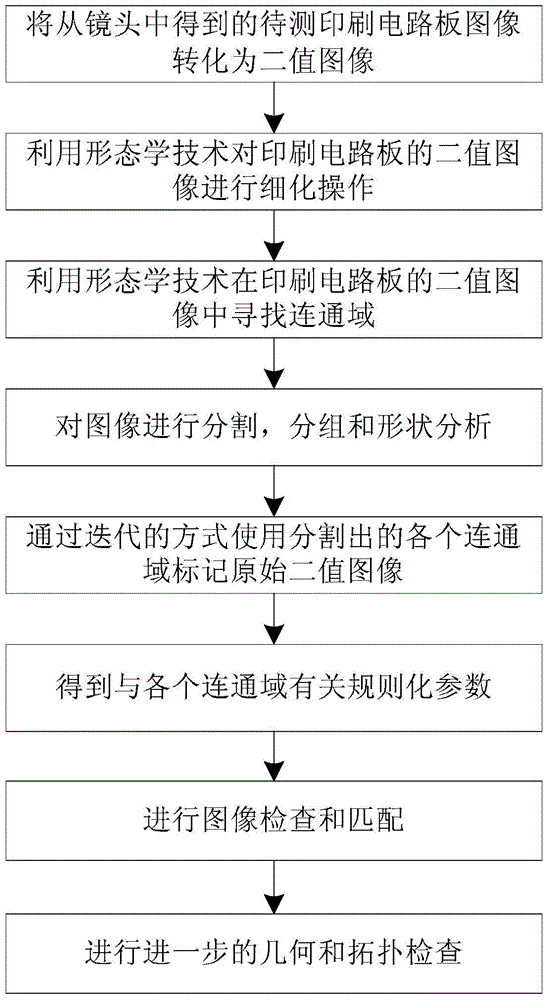

[0051] Such as figure 1 As shown, the printed circuit board defect detection method based on regular words parameters in this embodiment includes the following steps:

[0052] (1) This method needs to carry out the following 2 to 6 operations on the standard printed circuit board in advance to obtain relevant standard parameters and images;

[0053] (2) converting the printed circuit board image to be tested into a binary image;

[0054] (3) The binary image of the printed circuit board is thinned by mathematical morphology technology, and the obtained image is composed of lines with a single pixel width, and the global characteristics of the original image can be preserved.

[0055] That is, after a series of structural elements with a certain shape are given, the pixels that satisfy the hit transformation are deleted sequentially and cyclically, as follows:

[0056] If T is a collection of structural elements, X is the image to be thinned, and X is defined as:

[0057] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com