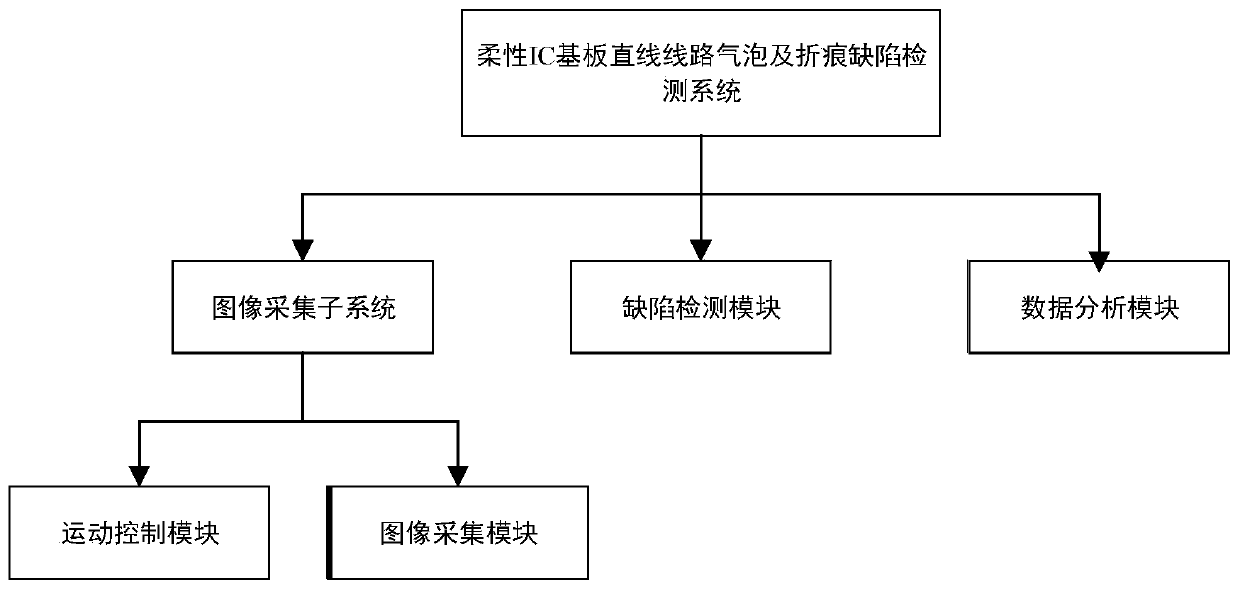

A system and method for detecting bubbles and crease defects in straight lines of flexible IC substrates

A defect detection and detection method technology, applied in the field of defect detection, can solve the problems of detection algorithms or few papers, and achieve the effect of avoiding false positives of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

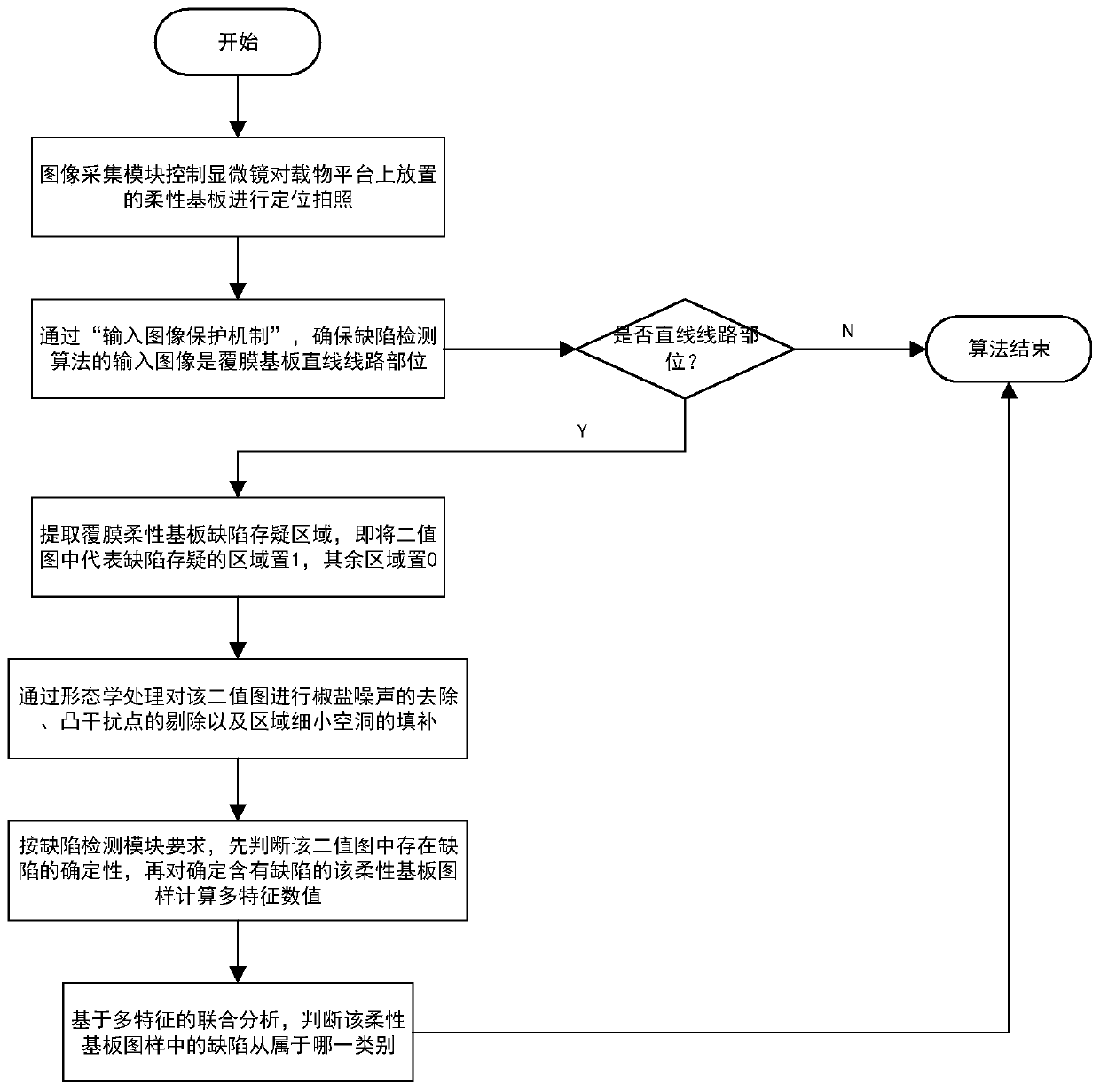

[0058] Such as figure 1 As shown, a method for detecting bubbles and crease defects in a straight line of a flexible IC substrate in this embodiment includes the following steps:

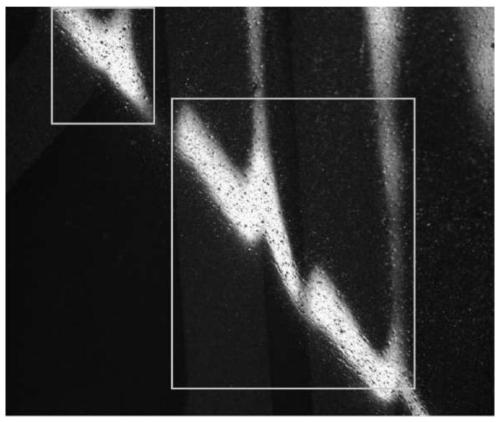

[0059] S1. The image acquisition subsystem controls the microscope to position and take pictures of the flexible substrate placed on the loading platform, and the target position is the area where the film-coated straight line is located;

[0060] S2. Through the "input image protection mechanism", ensure that the input image of the defect detection algorithm is the line part of the film-coated flexible substrate, otherwise a pop-up window will warn and exit the algorithm process;

[0061] S3. Extracting the area with doubtful defects in the film-coated flexible substrate, that is, setting the area representing doubtful defects in the binary image to 1, and setting the remaining areas to 0;

[0062] S4. Remove salt and pepper noise, remove convex interference points, and fill small holes in the bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com