fuel dispenser

A technology of fuel distributor and fuel distribution, which is applied in the direction of low-pressure fuel injection, low-pressure fuel injection, fuel injection device, etc., and can solve problems such as application range limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

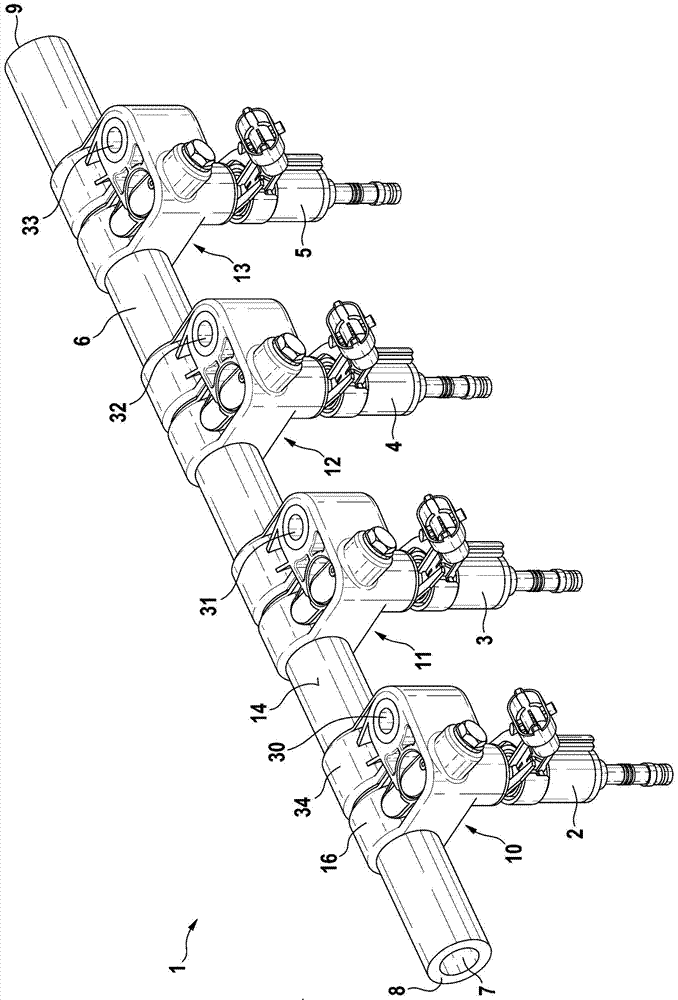

[0017] figure 1 A schematic perspective view of a fuel distributor 1 according to one embodiment of the invention is shown. Furthermore, fuel injection valves 2 , 3 , 4 , 5 mounted on fuel distributor 1 are shown. The fuel distributor 1 can in particular be designed in the form of a fuel distributor strip 1 . The fuel distributor 1 is particularly suitable for externally ignited internal combustion engines which compress the mixture. Here, the fuel distributor 1 is particularly suitable for medium-pressure systems. Here, the medium pressure for such a medium pressure system may be in the range of 3 MPa to 10 MPa or 30 bar to 100 bar. In particular, the medium pressure may be in the range of 5Mpa to 7Mpa or 50bar to 70bar. However, the fuel distributor 1 according to the invention is also suitable for other applications.

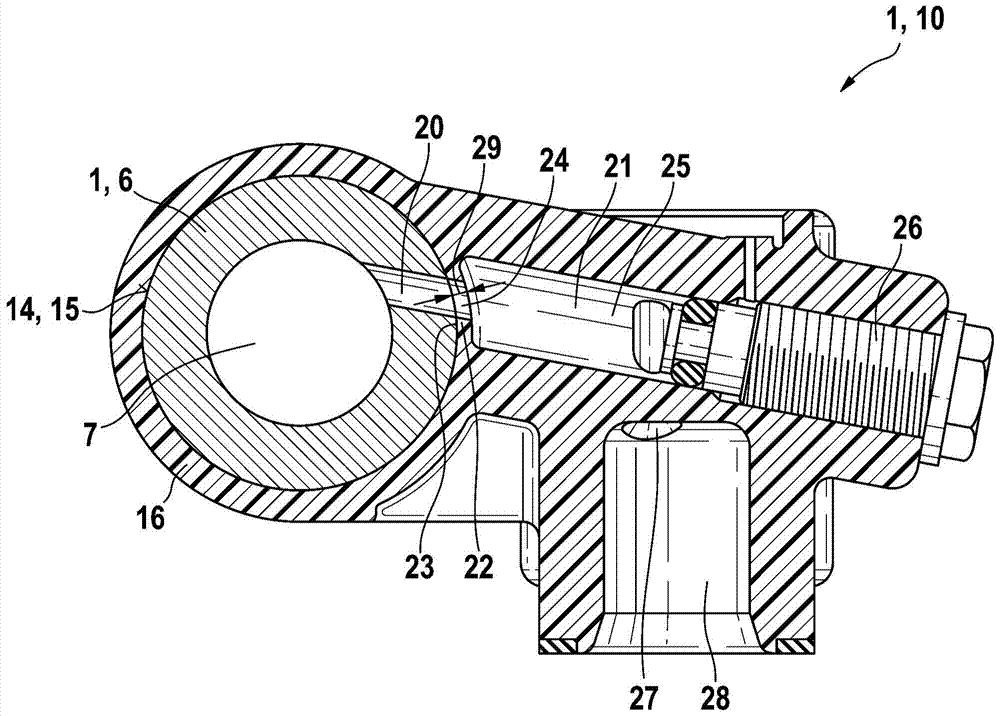

[0018] The fuel distributor 1 has a distributor body 6 . The distributor body 6 is designed as a tubular distributor body 6 in the present exemplary em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com