Metal liner

A metal gasket and substrate technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of not being able to guarantee the sealing characteristics for a long time, the life of the metal gasket is reduced, the surface pressure is unbalanced, etc., to ensure the sealing performance, improved fuel consumption, the effect of uniform surface pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

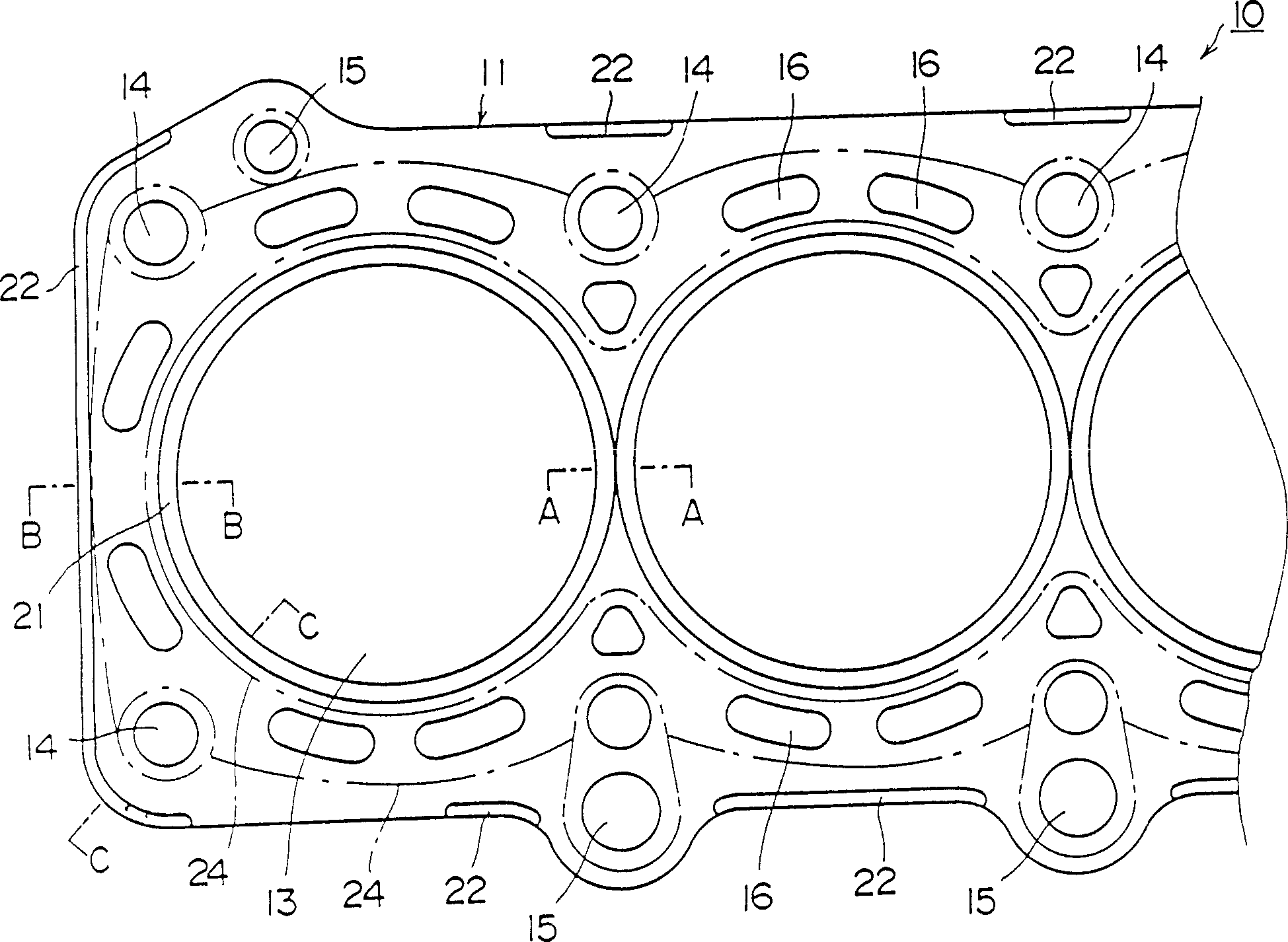

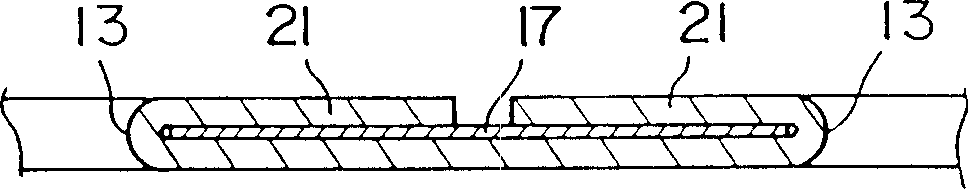

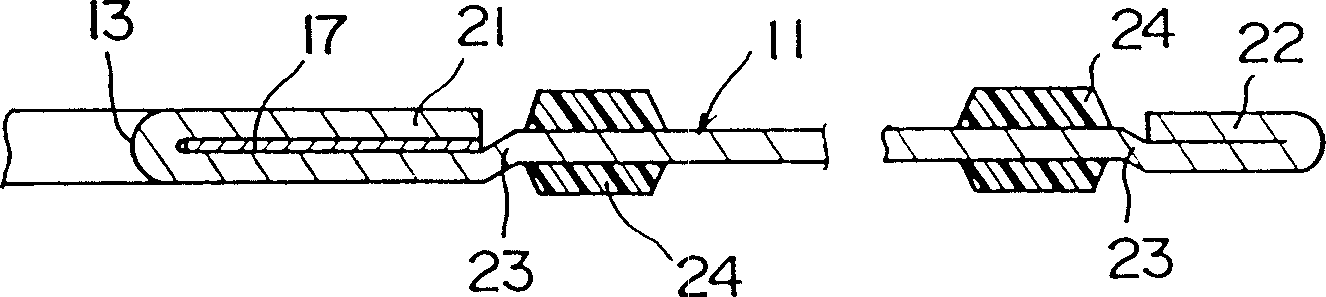

[0081] Figure 1-4 One embodiment of the invention is shown. The metal backing 10 includes a base plate 11 made of metal such as stainless steel, and a set of holes are formed in the base plate 11 . The base plate 11 includes the inner surface of each hole, and two joint surfaces surrounding each hole, which are covered with metal plating, resin coating, or a mixed coating of metal and resin. In addition, depending on the cylinder block and cylinder head constituting the engine To deal with the roughness of the joint surface, a surface treatment material 12 is baked on the surface of the substrate 11, such as fluorinated rubber, nitrile rubber (NBR), molybdenum disulfide and the like. exist Figure 4 In , the surface treatment material 12 is shown slightly exaggerated, but not shown in other figures.

[0082]One group of holes includes a group of cylinder bore holes 13 corresponding to the cylinder bore (combustion chamber) of the cylinder block, bolt holes 14 corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com