Technology and device for processing large linear outer plate of hull bulb bow

A processing device and processing technology are applied in the field of processing technology and processing device for the large linear outer plate of a hull bulb, which can solve the problems of difficult control of deformation, reduced production efficiency, poor processing and forming accuracy, etc., and it is difficult to achieve deformation. Control, reduce production efficiency, and ensure the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

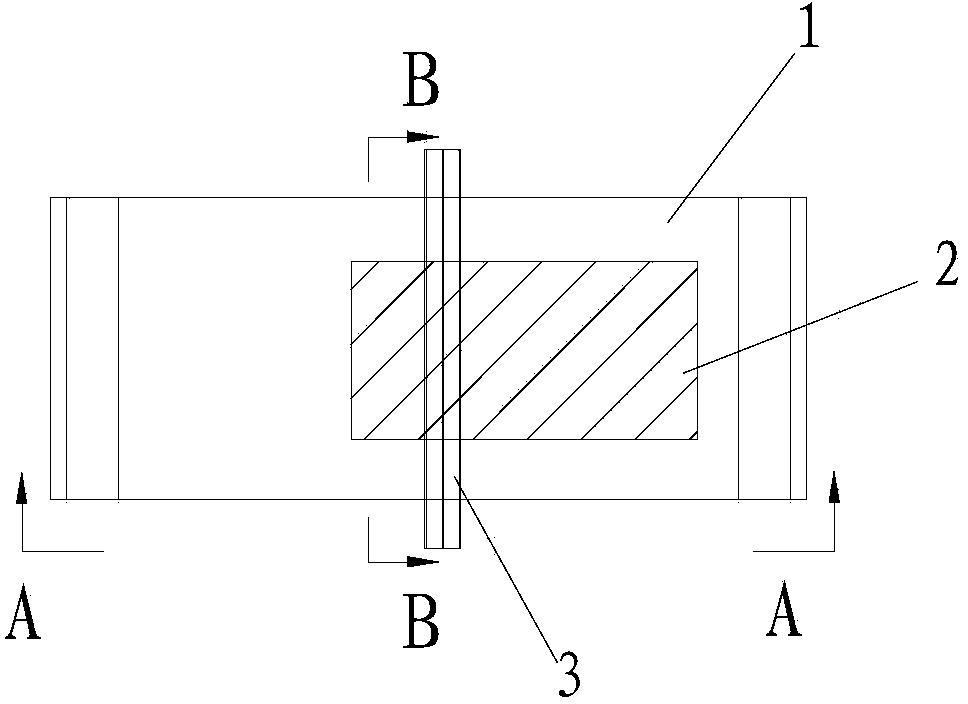

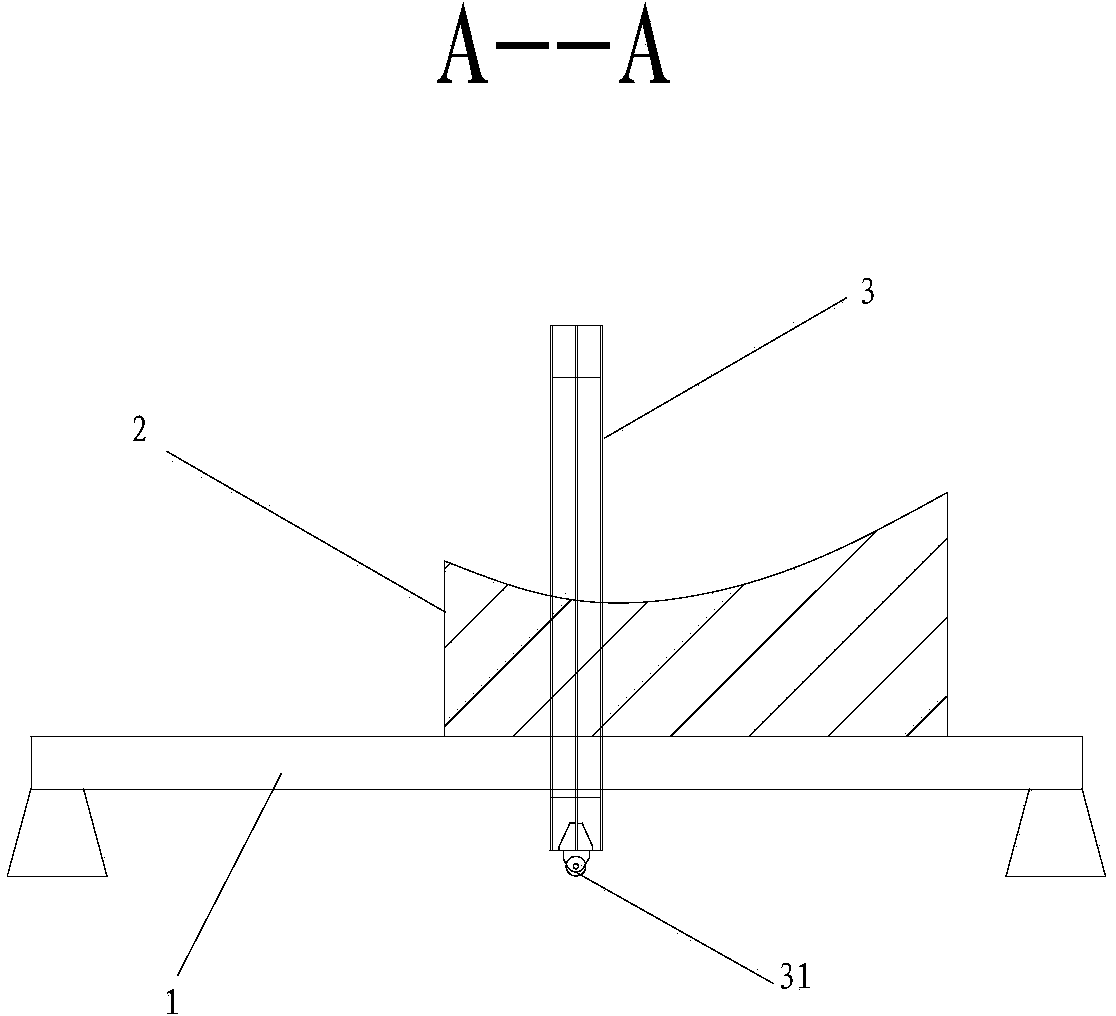

[0021] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

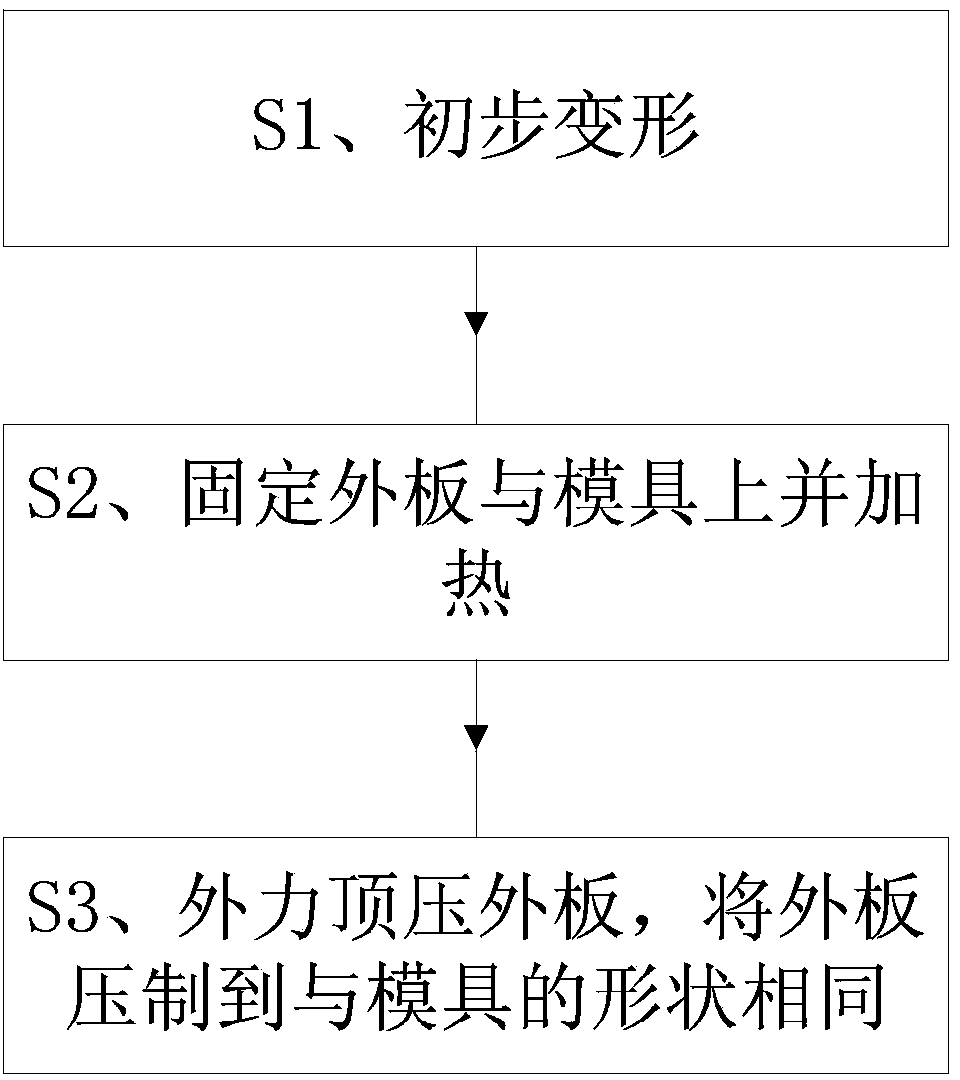

[0022] see figure 1 , a kind of processing technology of bulbous bow large linear outer plate of the present embodiment, it comprises steps:

[0023] S1. Carry out overall preliminary deformation of the outer plate to be processed;

[0024] S2. Correspondingly fixing the initially deformed outer panels on the mold, and performing heat treatment on the outer panels;

[0025] S3. Using external force to press the heated outer plate to the same shape as the mould.

[0026] The processing technology of the large linear outer plate of the bulbous nose of the hull of the present invention adopts the mode of the outer plate mold, combined with heat treatment, and then presses the heated outer plate to the same shape as the mold by external forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com