An inkjet printing device

An inkjet printing device and inkjet printing technology, applied in printing and other directions, can solve the problems of affecting the printing quality of printed images or content, increasing the difficulty and time of operation, and cumbersome placement process, so as to improve the design utilization rate and ensure Inkjet quality, the effect of expanding the printing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

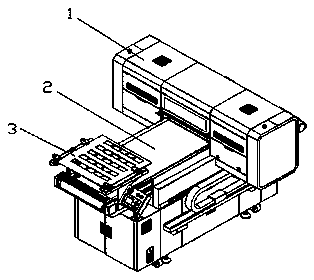

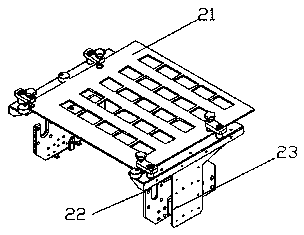

[0022] Such as figure 1 As shown, the inkjet printing device of the present invention includes a printing part 1, a feeding part 2 and a control system (not shown in the figure) for controlling the printing process. The position is to spray ink droplets to the object to be printed to realize the printing of images or characters. The control system also includes a manual button control board for controlling the conveyance of the feeding part 2 and the lifting movement of the jig 3 . The feeding part 2 includes a feeding station and a printing station, the feeding station is used for loading the object to be printed, and the printing station is used for the printing operation of the object to be printed. The control system controls the feeding part 2 to move along the forward direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com