Column crystal wafer moving device

A technology of moving sheets and column crystals, which is applied in the direction of conveyor objects, transportation and packaging, furnaces, etc., can solve the problems of high cost and long delivery time, and achieve the effect of short delivery time and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

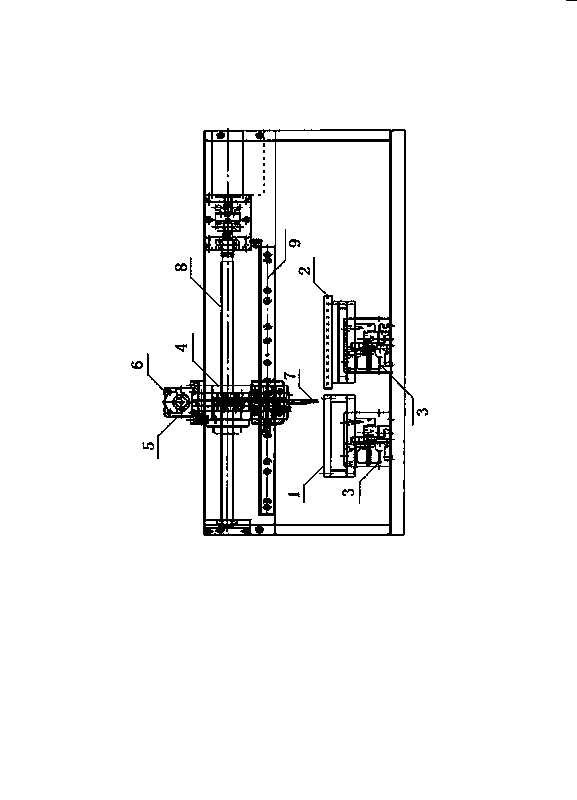

[0009] In the figure, the timing belt (3) is installed on the wafer tray (1) and the jig tooling (2), and drives the wafer tray (1) and the jig tooling (2) to move, and the eccentric wheel is installed on the motor (5) (6), connected with the suction part (4), the suction part (4) is installed on the ball screw (8), the suction head (7) is installed on the suction part (4), the suction head (7) ) adopts two directions of transmission, one is that the suction part (4) moves along the direction of the slide rail (9) under the action of the ball screw (8), and the other is that the motor (5) rotates to drive the eccentric wheel (6) , so that the material suction head (7) moves up and down to absorb material, and the performance meets the needs of use and the design requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com