Valves for beverage filling machines

A filling machine and beverage technology, applied in the direction of using back pressure filling, packaging, sliding valves, etc., can solve the problems of excessive energy, increased failure probability, and undesired problems, and achieve reliable closure, simple engineering structure, and energy saving The effect of structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Preferred embodiments will be described below with reference to the accompanying drawings. Here, identical, similar or identically functioning components in different drawings are marked with the same reference numerals, and repeated descriptions of such components are sometimes omitted in the following description to avoid redundancy.

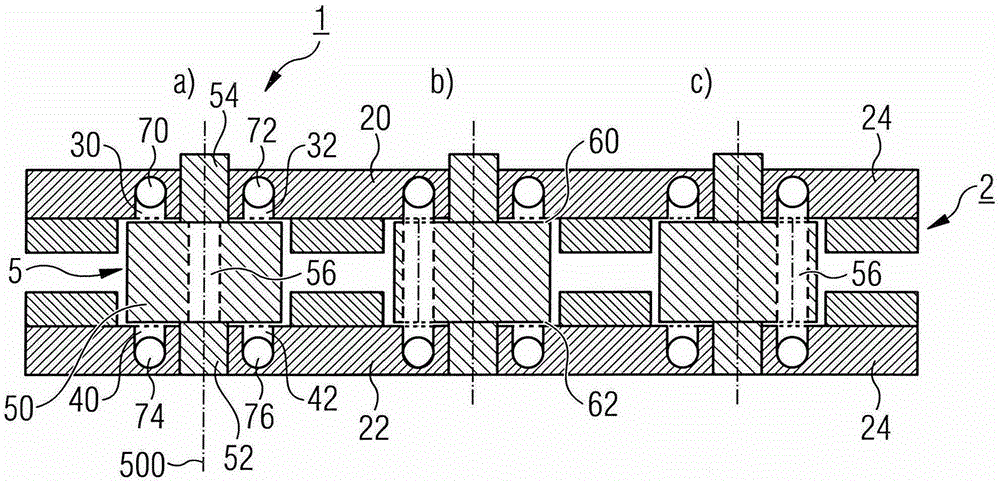

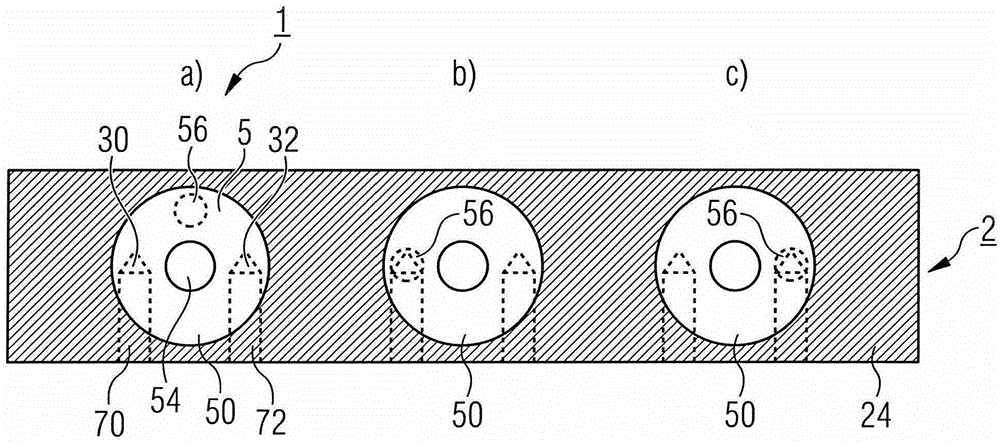

[0034] exist figure 1 A schematic cutaway side view of the proposed valve 1 is shown in , while in figure 2 Its corresponding schematic cross-sectional top view is shown in . exist figure 1 and figure 2 , three identical valves 1 arranged side by side are shown here respectively, labeled a), b) and c), wherein the three valves 1 are in figure 1 and figure 2 are in different on-off states. However, the following will mainly refer to the following examples figure 1 a) in and figure 2 Valve 1 shown in a).

[0035] Equipped with valve body 2, it is in such as figure 1 and figure 2 The illustrated embodiment has an upper port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com