Beamed yarn half dip-dyeing suction space dye device and method

A technology of warp beam yarn and warp beam, which is applied in the field of space dyeing, can solve the problems of monotony, no novelty, no novel style, single full-color style, etc., and achieve the effect of satisfying design and aesthetics, rich layers, and colorful fabric colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

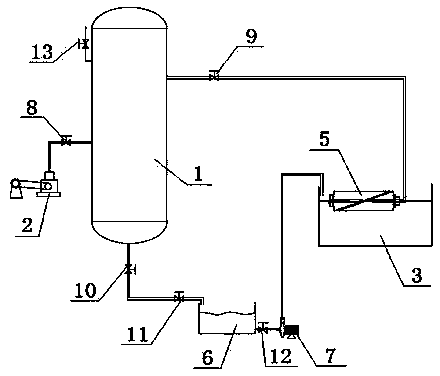

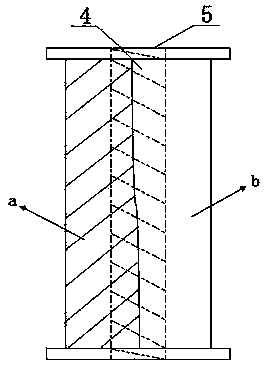

[0034] Such as figure 1 As shown, the present invention discloses a suction section dyeing device for warp beam semi-exhaust dyeing. The device is composed of three parts: a vacuum system, a suction system and a circulation system. The vacuum system includes a vacuum tank (1) and a matching The vacuum pump (2) for vacuuming, the suction system includes the dye pool (3) and the dye column (4) fixed in the pool and used to sleeve the warp beam (5), the circulation system includes the liquid storage tank (6) and the The pumping pump (7) at the lower end of the liquid storage tank (6) or the lower end; wherein, the upper middle part of the vacuum tank (1) is connected to one end of the dyeing column (4) through the No. 1 pipeline, and the The lower part of the vacuum tank (1) is connected to the liquid reservoir (6) through the No. 2 pipeline, and the liquid reservoir (6) is connected to the The dye pool (3) is connected.

[0035] The No. 1 pipeline is provided with a No. 2 valv...

Embodiment 2

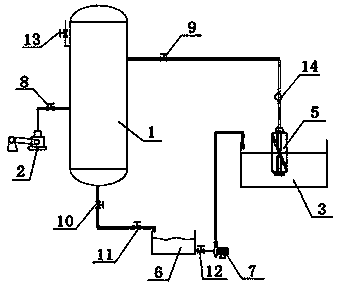

[0056] Such as figure 2 As shown, the present invention discloses a suction section dyeing device for warp beam semi-exhaust dyeing. The device is composed of three parts: a vacuum system, a suction system and a circulation system. The vacuum system includes a vacuum tank (1) and a matching The vacuum pump (2) for vacuuming, the suction system includes the dye pool (3) and the dye column (4) fixed in the pool and used to sleeve the warp beam (5), the circulation system includes the liquid storage tank (6) and the The pumping pump (7) at the lower end of the liquid storage tank (6) or the lower end; wherein, the upper middle part of the vacuum tank (1) is connected to one end of the dyeing column (4) through the No. 1 pipeline, and the The lower part of the vacuum tank (1) is connected to the liquid reservoir (6) through the No. 2 pipeline, and the liquid reservoir (6) is connected to the The dye pool (3) is connected.

[0057] The No. 1 pipeline is provided with a No. 2 val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com