Dynamic compaction machine construction real-time monitoring method and system based on pounder impact acceleration measurement

A technology of acceleration measurement and real-time monitoring, applied in infrastructure engineering, on-site foundation soil survey, soil protection and other directions, can solve problems such as inability to guarantee vision sensors, blocking sensor measurement, harsh construction environment, etc., and achieve accurate detection results. , The effect of simple debugging and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

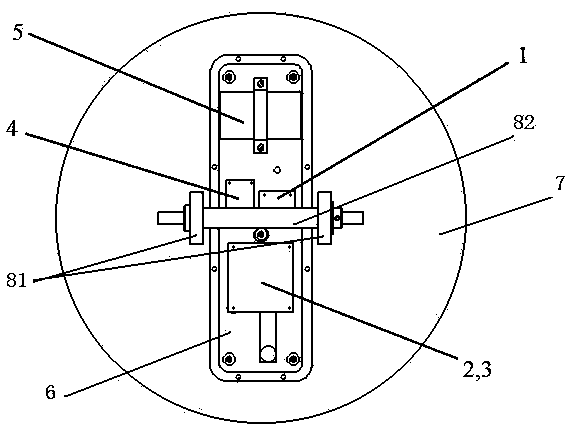

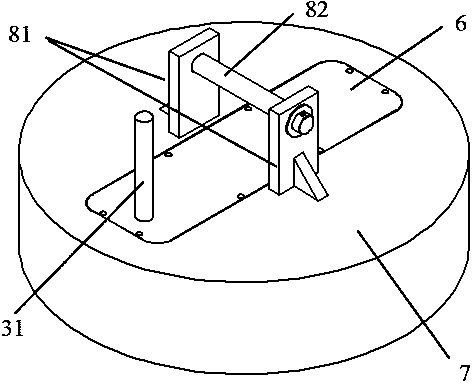

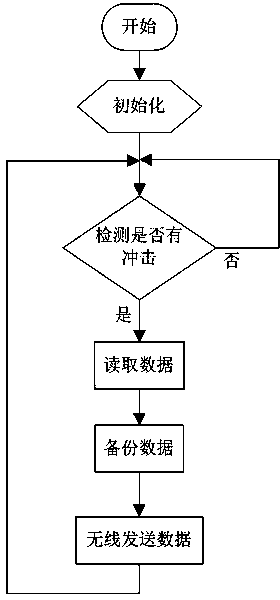

[0034] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0035] 1. The design idea is the principle of the present invention:

[0036] Before tamping, the soil at the tamping point is soft, the impact time of the ram hammer on the ground is long, the ground cushioning effect is good, and the peak acceleration is small. During tamping, a hard shell is gradually formed below the rammed pit from top to bottom, and the yield stress of the upper layer of soil is close to or greater than the additional stress of the impact load of dynamic tamping. The dynamic response of the upper layer of soil is mainly elastic, and most of the ramming energy is consumed in A small part of the compaction of the soil is consumed by the elastic vibration and damping vibration of the soil. As the number of tamping strikes increases, the hard shell layer whose dynamic response is mainly elastic in the soil gradually expands...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com