10kv high pressure spring switch

A 1.10kv, high-voltage technology, applied in the direction of protection switch operation/release mechanism, contact drive mechanism, etc., can solve the problems that the drop switch can only be manually debugged, it is difficult to realize electric control, and hidden dangers to personal safety, so as to save manpower, Simplified operation, safe and reliable closing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

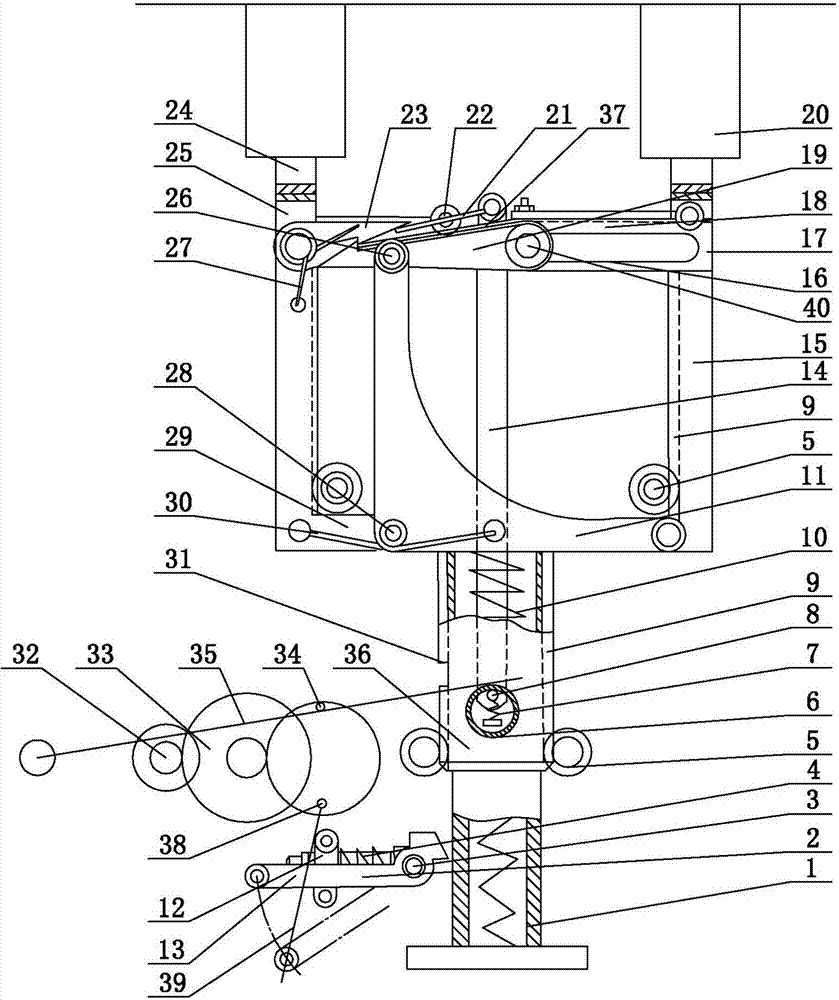

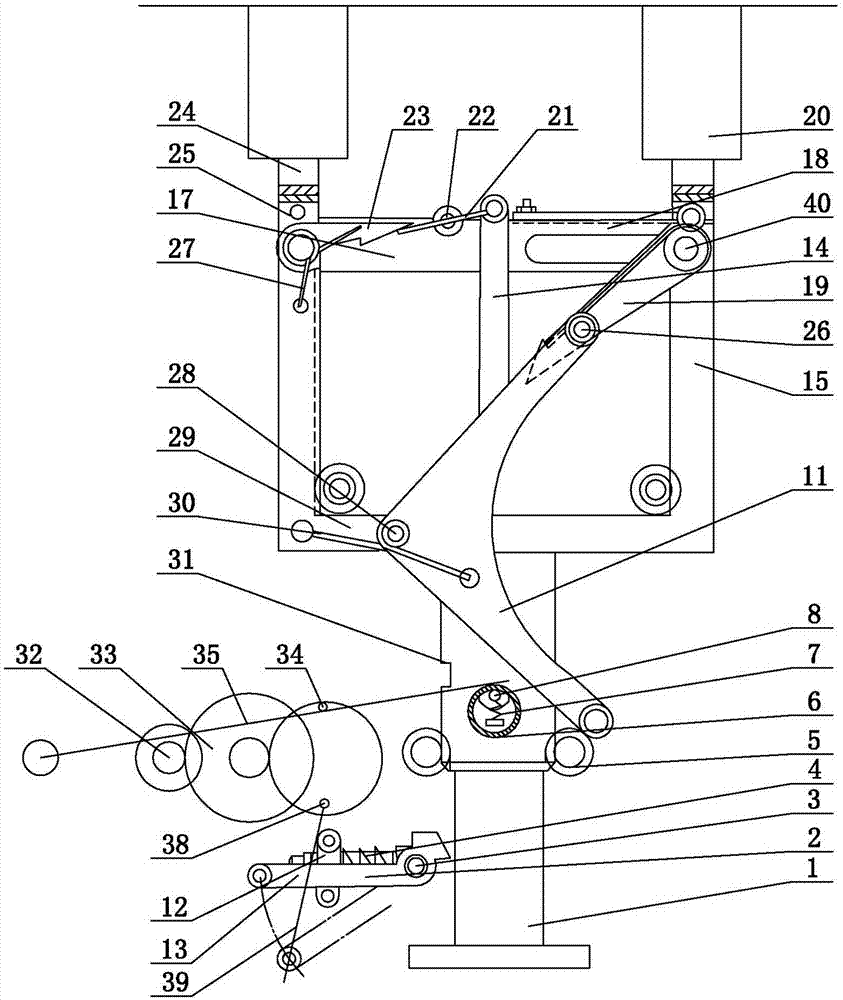

[0020] The present invention includes a support frame 17 composed of vertical rods 15 on both sides and a lower cross rod 29, and its structural points are provided with movable contacts 25 above the vertical rods 15 on both sides of the support frame 17, and the two movable contacts 25 are electrically connected. A vertical guide sleeve 36 is provided below the lower cross bar 29 of the support frame 17, and the vertical guide sleeve 36 is connected with the guide column 1 with the first pressure spring 10 on the base; the vertical guide sleeve 36 is provided with a gap 31 on the side, corresponding to A locking device 2 is provided in the notch 31 of the vertical guide sleeve 36 .

[0021] As a preferred solution of the present invention, the upper ends of the two vertical rods 15 are connected by an upper cross rod 18, one side of the upper cross rod 18 is provided with a transverse guide groove 16, and a guide shaft is provided in the transverse guide groove 16 40, the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com