A rotor current recovery feedback device for a slip-wound rotor motor

A rotor motor and feedback device technology, applied in the electronic field, can solve the problems of rotor winding induced current and induced voltage waste, and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 is described by taking a three-phase slip-wound rotor motor as an example.

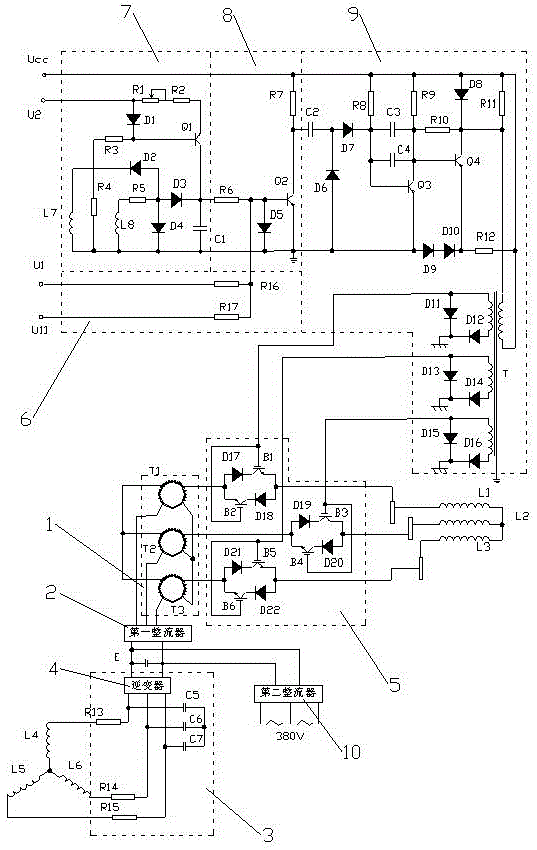

[0032] Such as figure 1 As shown, a rotor current recovery feedback device for a slip-wound rotor motor includes a frequency conversion and voltage conversion circuit 1 , a first rectifier 2 , an inverter circuit 3 , a chopper circuit 5 and a high frequency oscillation circuit 6 .

[0033] Frequency conversion and voltage conversion circuit 1, changing the frequency and voltage of the rotor winding induced current of the slip-wrapping rotor motor and outputting it;

[0034] The first rectifier 2 is connected to the output end of the frequency conversion and voltage conversion circuit 1, and rectifies the AC voltage output by the frequency conversion and voltage conversion circuit 1;

[0035] The inverter circuit 3 is connected to the output terminal of the first rectifier 2, converts the DC voltage into a three-phase AC voltage, and outputs it to the stator winding of the slip-wra...

Embodiment 2

[0050] Embodiment 2 is described by taking a three-phase slip-wound rotor motor as an example.

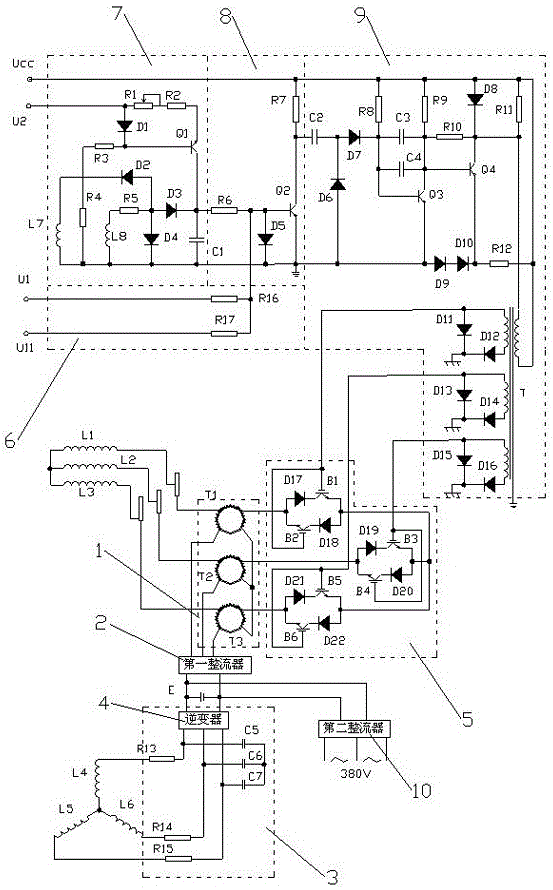

[0051] Such as figure 2 As shown, a rotor current recovery feedback device for a slip-wound rotor motor includes a frequency conversion and voltage conversion circuit 1 , a first rectifier 2 , an inverter circuit 3 , a chopper circuit 5 and a high frequency oscillation circuit 6 .

[0052] Frequency conversion and voltage conversion circuit 1, changing the frequency and voltage of the rotor winding induced current of the slip-wrapping rotor motor and outputting it;

[0053] The first rectifier 2 is connected to the output end of the frequency conversion and voltage conversion circuit 1, and rectifies the AC voltage output by the frequency conversion and voltage conversion circuit 1;

[0054] The inverter circuit 3 is connected to the output terminal of the first rectifier 2, converts the DC voltage into a three-phase AC voltage, and outputs it to the stator winding of the slip-wr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com