Noodle processing equipment

A processing equipment and noodle technology, which is applied in the field of noodle processing machines, can solve the problems of inconvenient operation, inconvenient for small users, and large space occupied by equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

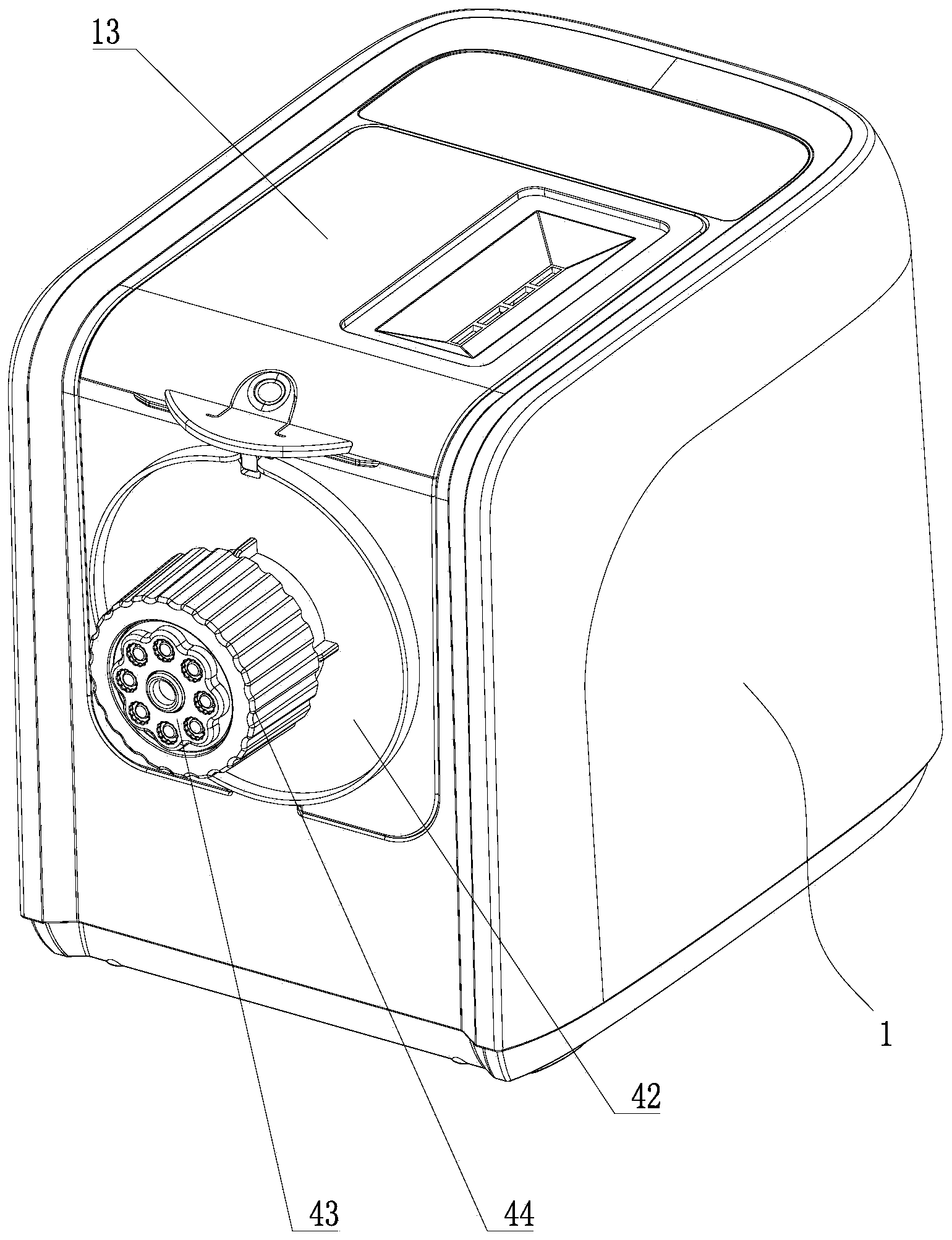

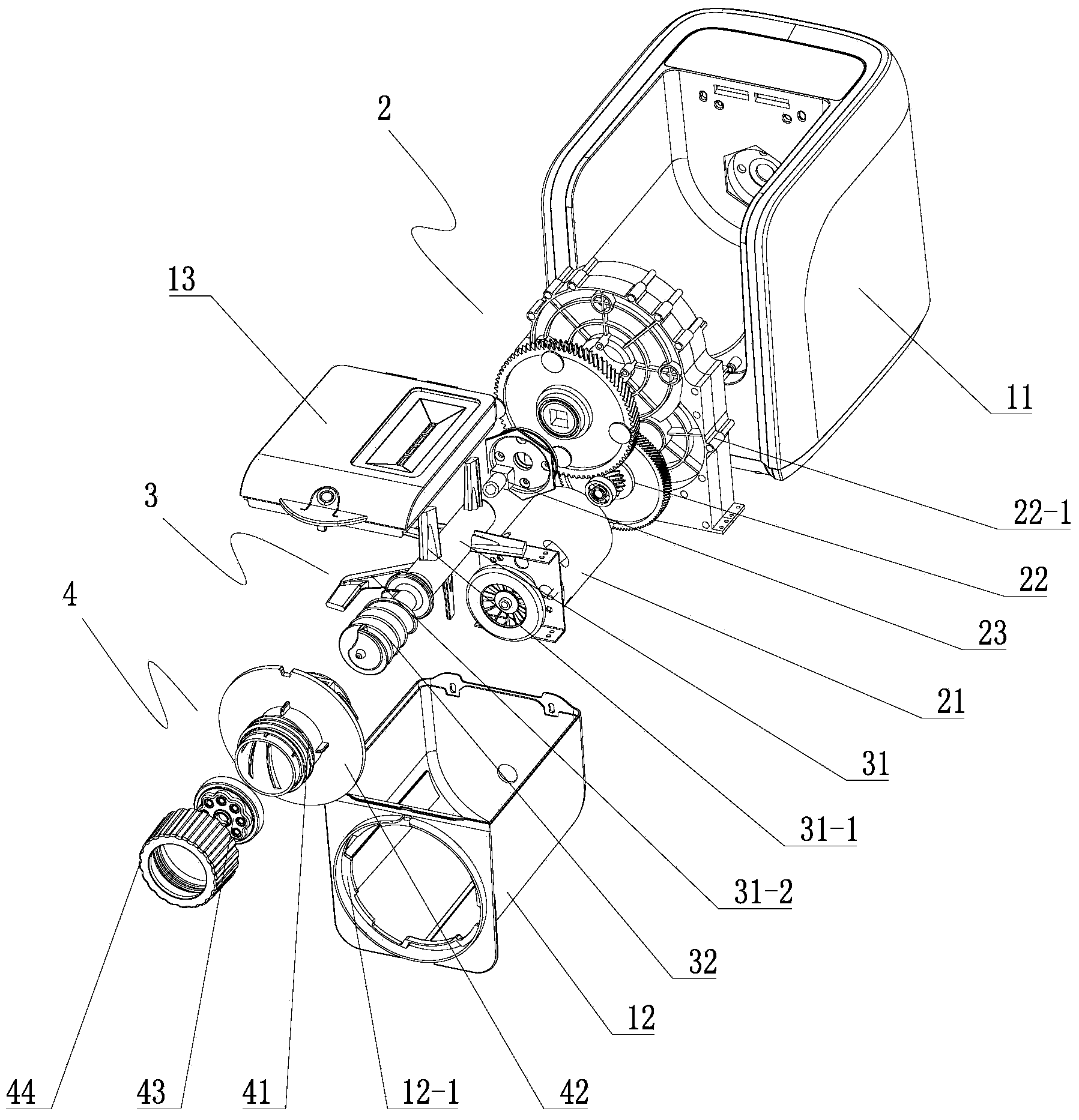

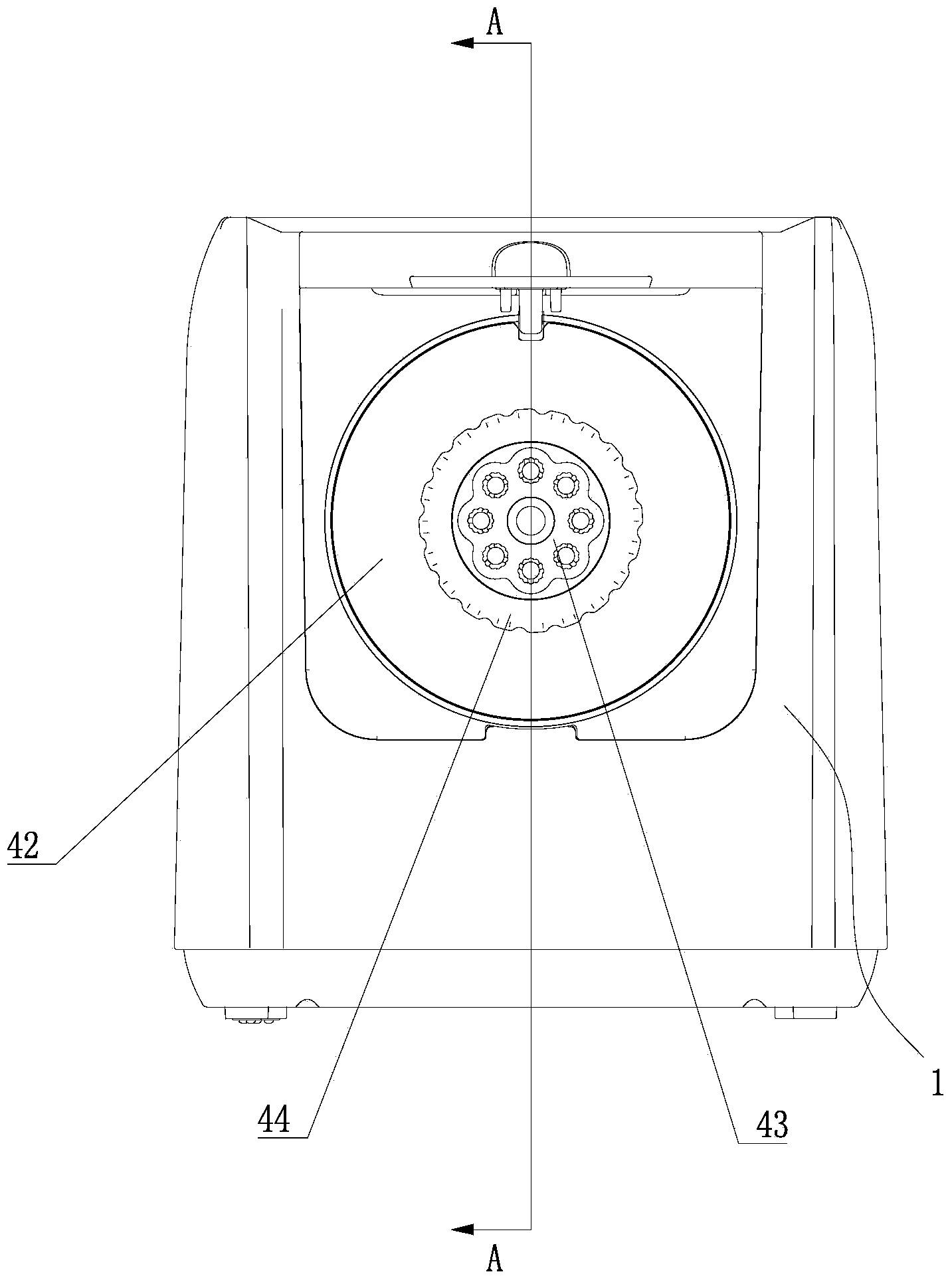

[0022] like Figure 1 to Figure 4 Shown is the noodle machine of the present invention, including a casing 1 forming a fuselage, and the specific structure is as follows figure 2 As shown, the housing 1 includes a casing 11 and a stirring chamber 12. In the figure, the casing 11 and the stirring chamber 12 are arranged separately to ensure the sealing of the stirring chamber 12, and more safe, hygienic and durable materials can be used to ensure the reliability of the stirring chamber 12. , safety, of course, the stirring chamber 12 and the outer shell 11 can also be set as a whole, which is not shown in detail in the figure, and a cover plate 13 is provided on the stirring chamber 12 . A driving device 2 is provided in the housing 1, and the driving device 2 provides a power source for the noodle machine. The structure (will be described in detail later), the driving device 2 has two states of forward and reverse, and the noodles are mixed during forward rotation, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com