Smashing machine for rolling viscous food raw materials

A technology for sticky food and tamping machine, which is applied in the field of tamping and twisting machine for rolling viscous food raw materials, can solve the problem of low degree of mechanization, restricting the development and application of food industrialization, and unable to carry out industrialized production and development, etc. problem, to achieve the effect of increasing the delicate feeling and improving the processing efficiency of tamping and rolling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

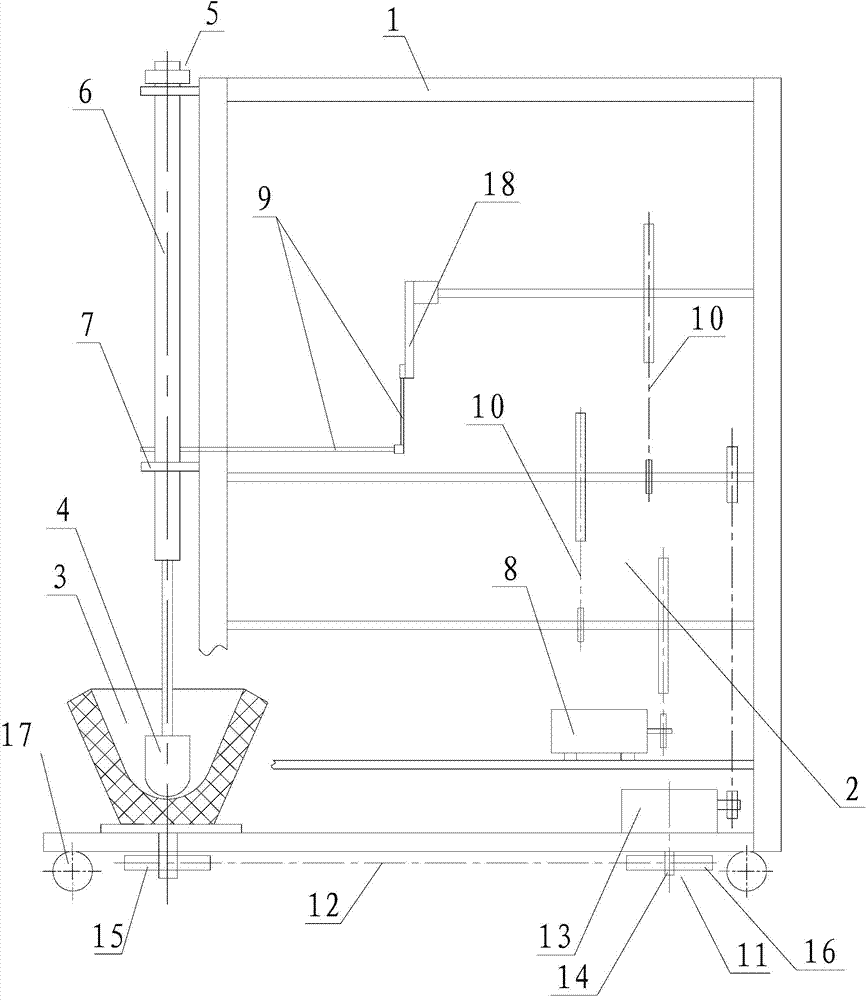

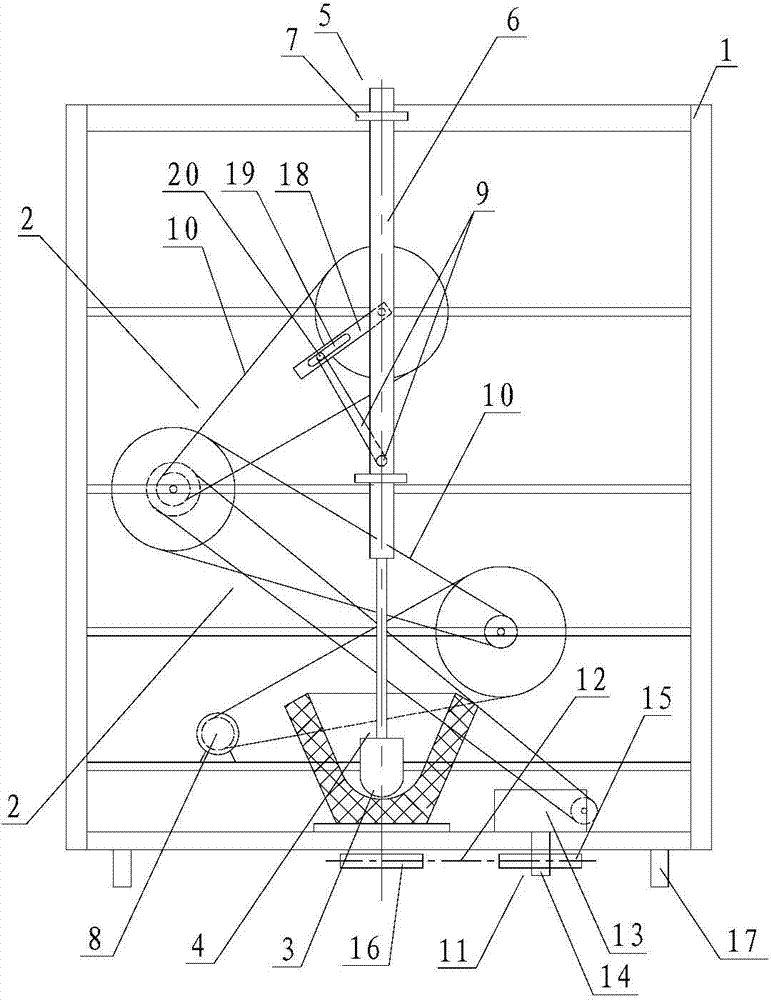

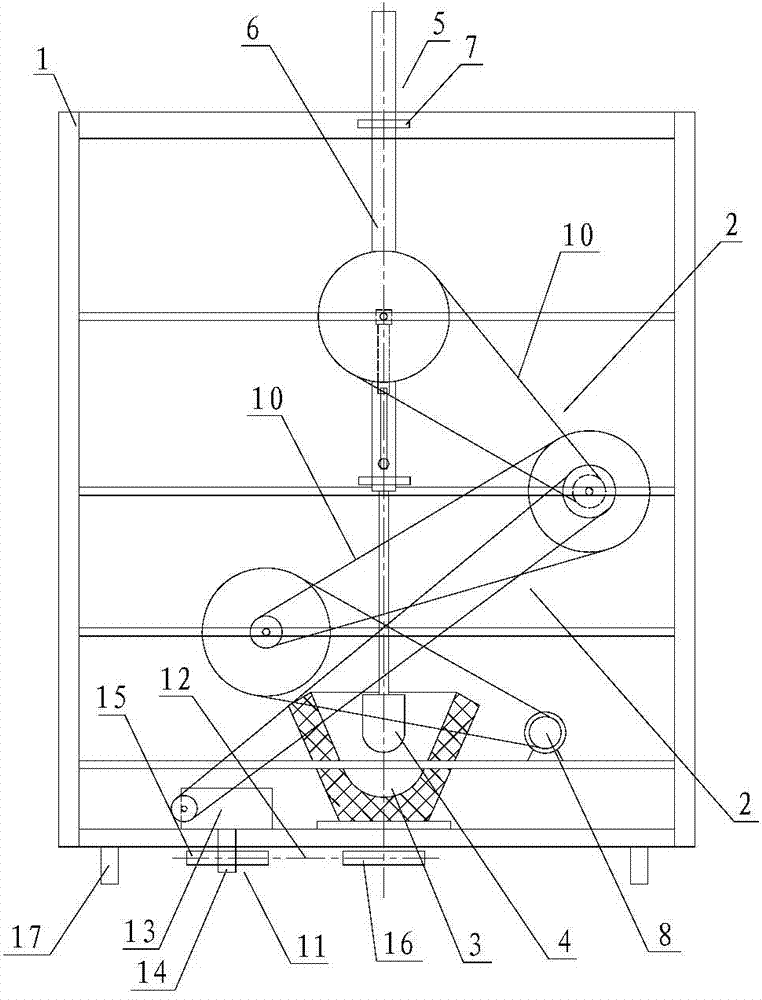

[0020] Such as figure 1 , figure 2 , image 3 as well as Figure 4 Shown is a tamping machine for kneading viscous food raw materials provided by the present invention, which can obviously improve the processing efficiency of viscous food raw materials and is convenient for industrial development and application. Described tampering machine comprises frame 1, power system 2, tampering groove 3 and contains the tampering device 5 of tampering head 4, and described tampering groove 3 openings are upwardly installed on the bottom of described frame 1, so The power system 2 described above is installed on the frame 1, and the ramming head 4 is installed on the frame 1 directly above the ramming groove 3 through the ramming device 5, and is positioned at the ramming device 5. The tamping head 4 directly above the trough 3 can reciprocate vertically in the tamping trough 3 driven by the power system 2 . Due to the structure of the tamping head 4 of the tamping machine, the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com