Preparation method of concentrated high-protein yoghurt before fermentation

A high-protein, concentrated technology, applied in the direction of milk preparations, dairy products, milking equipment, etc., can solve the problems of lower consumer acceptance, lower production efficiency, and excellent texture of yogurt, so as to improve the soft and delicate texture , shorten the fermentation time, the effect of soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

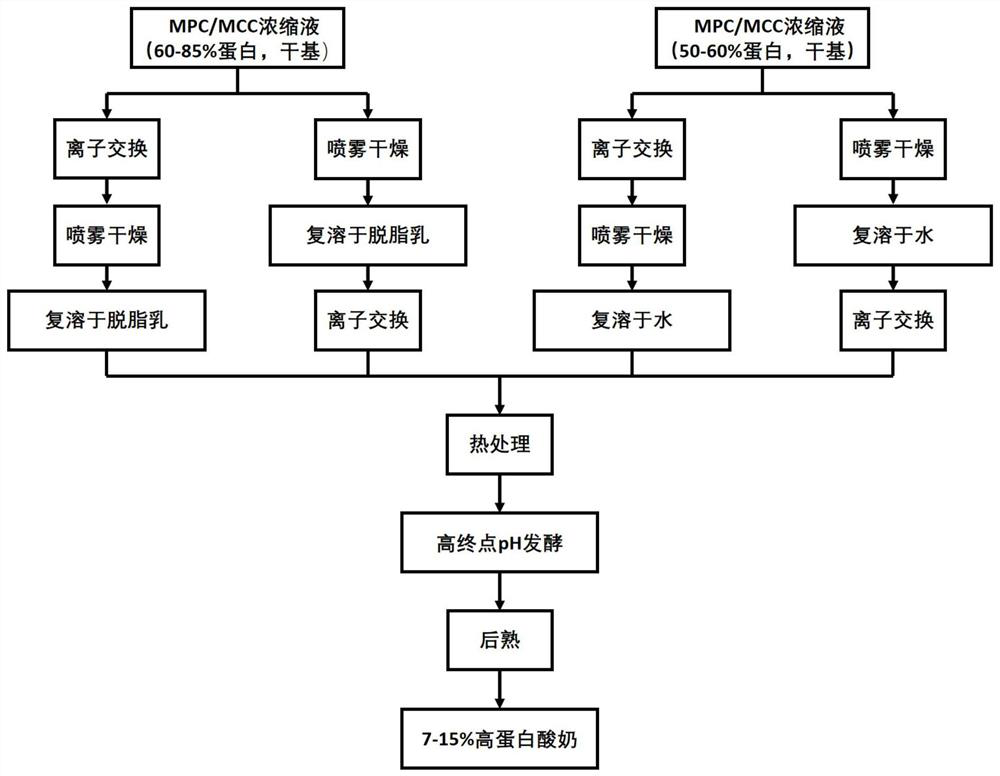

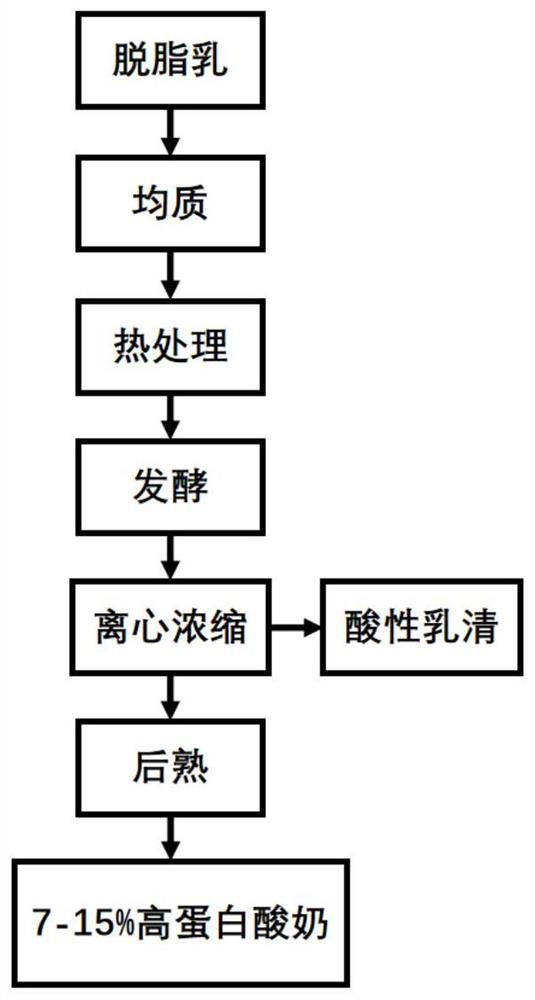

Method used

Image

Examples

preparation example Construction

[0062] The preparation steps of MPC are: taking fresh milk, defatting (9000rpm) with a disc centrifuge, and sterilizing the skim milk (72°C, 15s); Add water to the retentate to the initial volume of skim milk, continue diafiltration, control the temperature of ultrafiltration and diafiltration to 45-50°C, and collect the retentate as the MPC concentrate; spray dry the concentrate, air inlet and outlet The temperature was 135°C and 75°C, respectively, to obtain MPC powder.

[0063] The MCC preparation steps are: adjusting the ultrafiltration in the MPC preparation step to microfiltration, using a ceramic membrane with a pore size of 100 nm, and keeping other steps consistent with the MPC preparation steps, to obtain MCC concentrate and powder.

[0064] In the MPC and MCC preparation steps, the concentration times of the ultrafiltration / microfiltration stage, the diafiltration stage and the dry basis content of protein and lactose in the corresponding obtained MPC and MCC are sh...

Embodiment 1

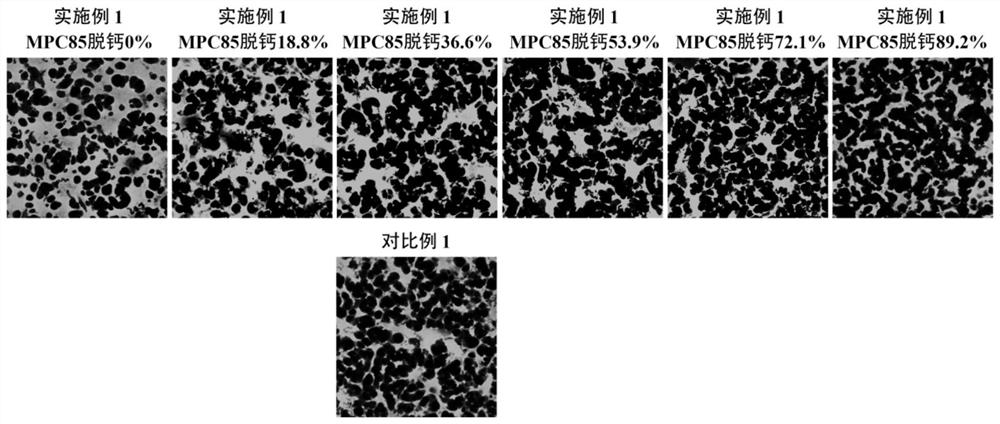

[0068] Example 1 Preparation of high protein yogurt by redissolving decalcified MPC85 powder in skim milk before fermentation: the effect of decalcification rate of MPC85 powder in the decalcification treatment alone

[0069] A method for preparing concentrated high-protein yogurt before fermentation, comprising the steps of:

[0070] Preparation of decalcified MPC85 powder: take MPC85 concentrate (the dry basis percentage of protein is 85.2%), add water to dilute to the total protein content of 5.80%, in which the mass ratio of casein and whey protein is 4:1, the casein The content is 4.64%; the ion exchange resin Amberlite SR1L Na is added to the diluent, and the addition amount is 0, 1.09, 2.14, 3.34, 5.36 or 9.53g resin / 100g diluent, and the corresponding ratio of resin to casein is 0, 23.5, 46.1, 72.0, 115.5 or 205.4g resin / 100g casein, kept at 300rpm for 3h, and then filtered with a 200-mesh filter bag to remove the resin; the filtrate was spray-dried, and the inlet and ...

Embodiment 2

[0091] Example 2 Preparation of high-protein yogurt by redissolving MPC85 powder in skim milk before fermentation: the effect of base decalcification in decalcification alone

[0092] A method for preparing high-protein yogurt, comprising the steps of:

[0093] High-protein base material preparation: take MPC85 powder (the dry basis percentage of protein is 85.2%), redissolve it in skim milk, so that the total protein content in the reconstituted solution is 9.0%, stir and dissolve for 30min, and then circulate at 25mPa. The protein content of the skim milk itself was 3.2%, the mass ratio of the protein brought by the skim milk and MPC85 powder in the reconstituted solution was 3.2:5.8, and the casein and whey protein in the reconstituted solution The mass ratio is 4:1, and the content of casein is 7.20%;

[0094] Decalcification treatment of high-protein base material: Add ion exchange resin Amberlite SR1L Na to the high-protein base material in an amount of 0, 1.05, 2.07, 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com