Sheet material edge cutter and sheet material processing method

A processing method and edge trimming machine technology, applied in metal processing, manufacturing tools, and other manufacturing equipment/tools, etc., can solve problems such as low production efficiency, complicated procedures, and inability to ensure consistency of steel doors, and achieve high production efficiency , The processing procedure is simple, the effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

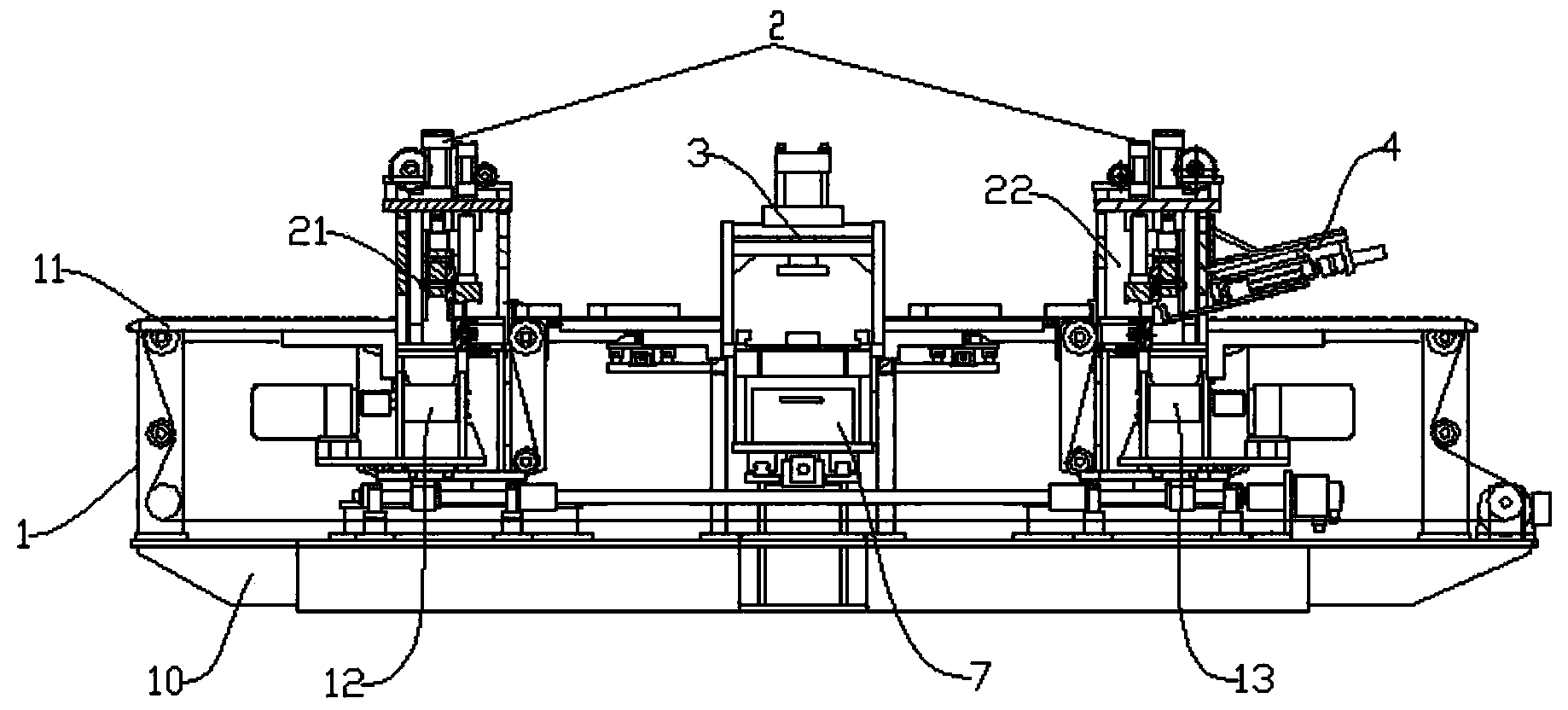

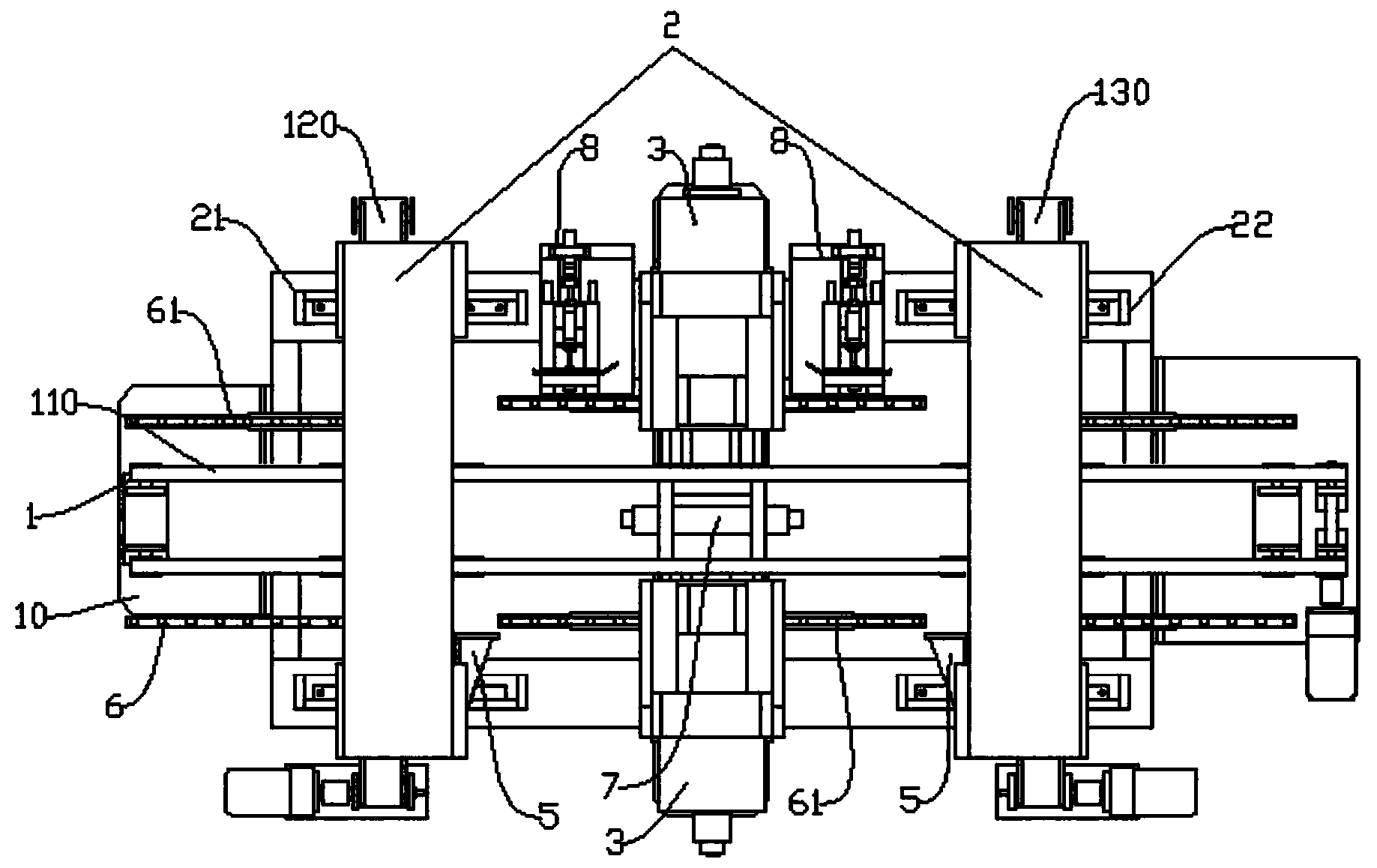

[0031] Such as figure 1 As shown, a kind of panel trimming machine of the present invention comprises: conveying device 1 and shearing unit 2, and shearing unit 2 is arranged on the conveying line of conveying device 1, is used for compacting sheet material and to the sheet material Multiple sides are cut at the same time; the edge cutting machine also includes a punching mechanism 3, which is arranged on the conveying line of the conveying device 1, and is used for punching on the sheet while cutting the sheet. hole. When using the sheet material trimming machine of the present invention to process the sheet material during steel door production, first start the conveying device 1 to transport the sheet material to the shearing unit 2, and then st...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap