Double-color injection molding machine with rotating shaft and rotary disc functions

A two-color injection and rotating shaft technology, which is applied in the field of two-color injection machines with turntable functions, can solve problems such as waste of cost, time-consuming construction, and complex structure, and achieve the effects of reducing production costs, reducing mechanism wear, and reducing assembly timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

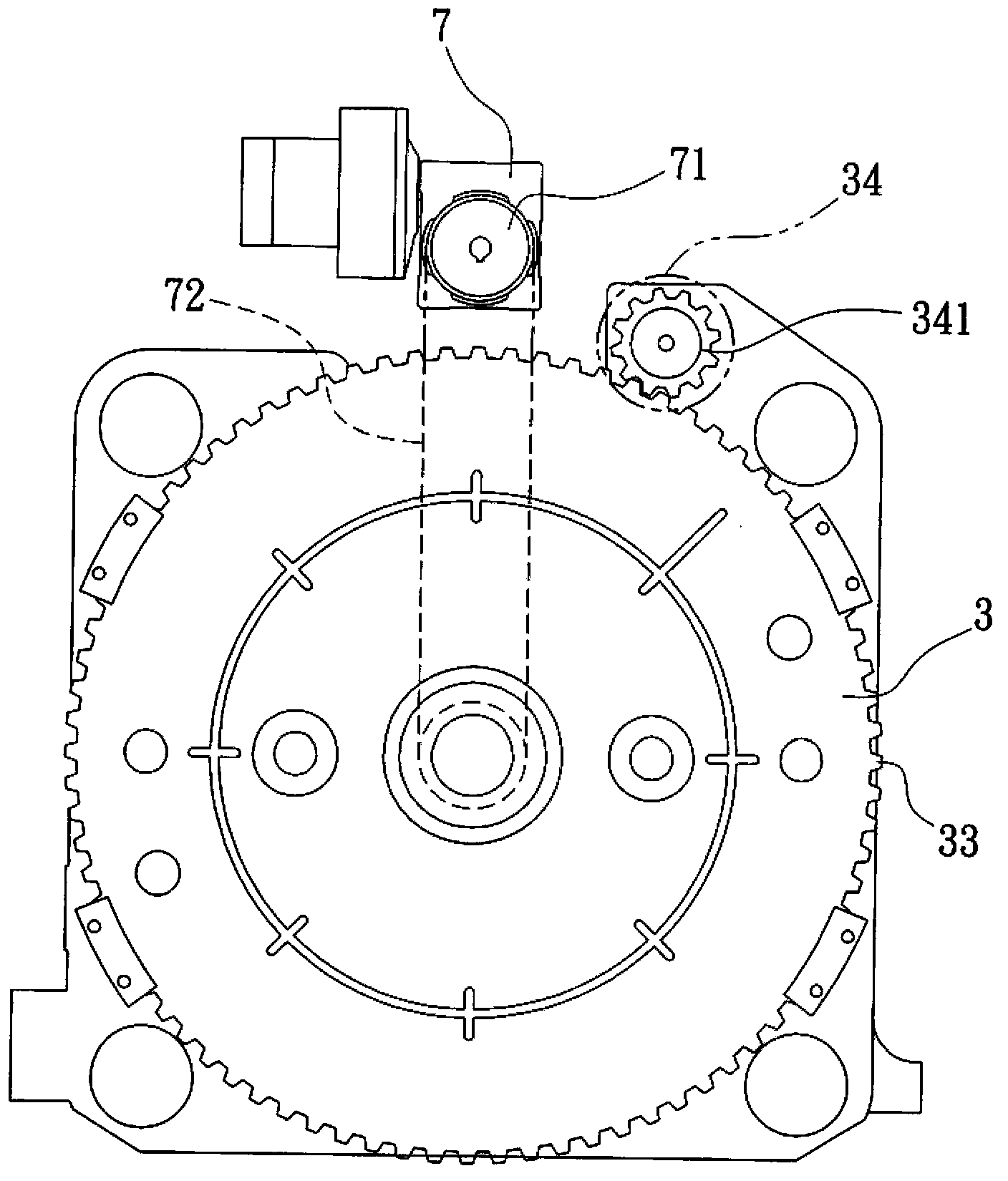

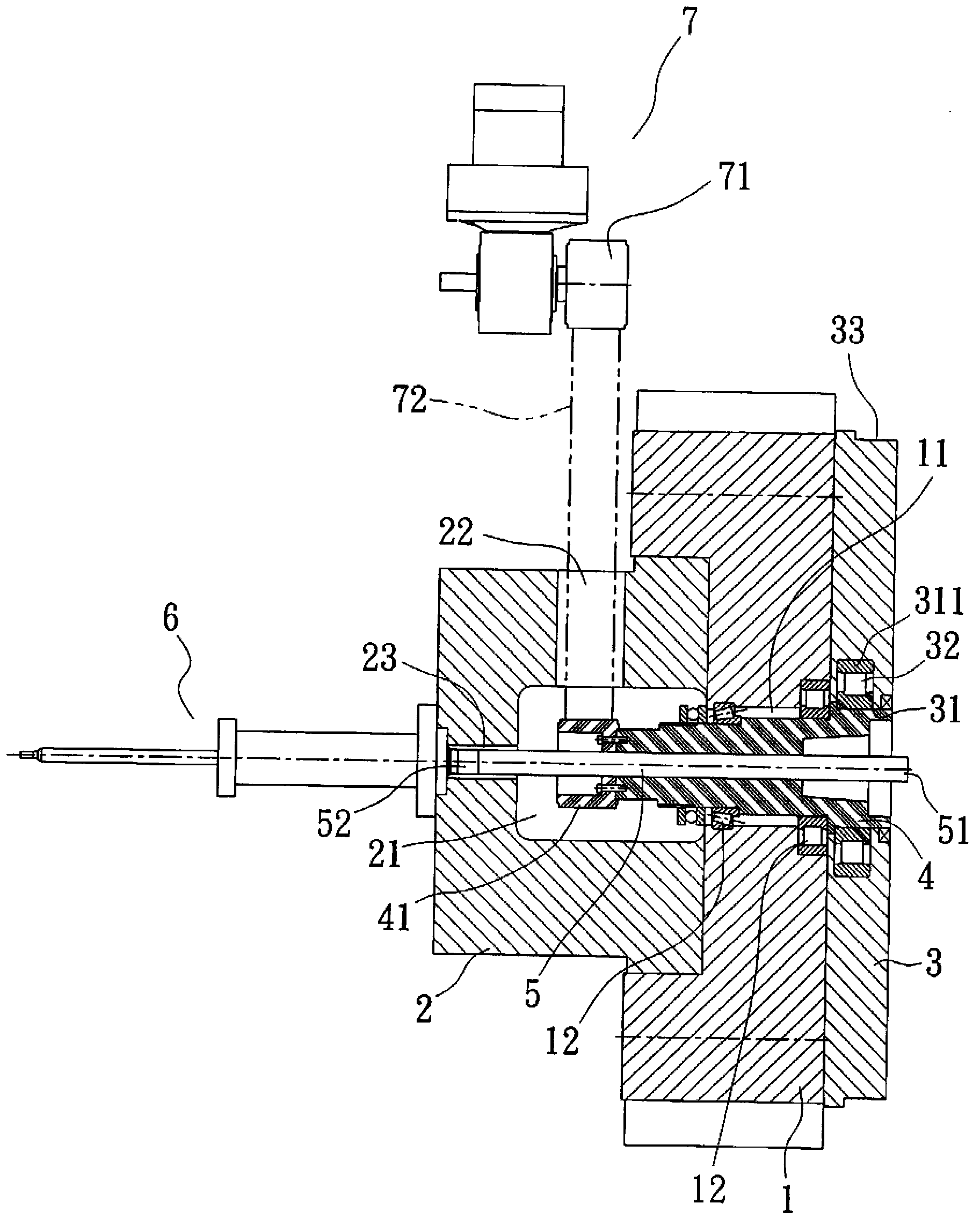

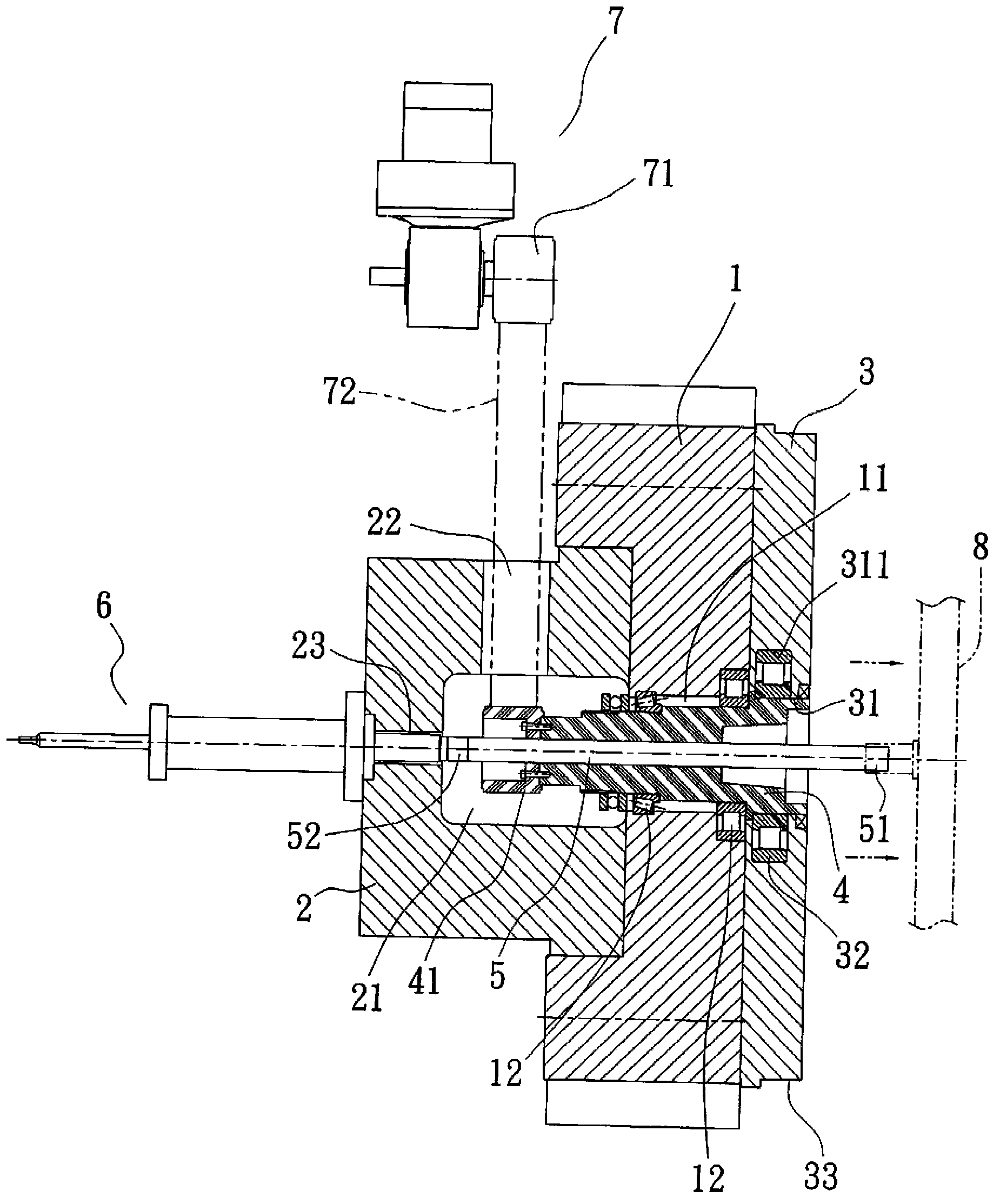

[0043] First, see figure 1 and 2 As shown, it is a front view and a cross-sectional schematic view of the two-color injection machine with the functions of the rotating shaft and the turntable of the present invention, which includes:

[0044] A body 1, which is provided with a shaft hole 11, and a second bearing 12 is provided at the front and rear ends of the shaft hole 11;

[0045] A base 2 is positioned at one end of the main body 1 for corresponding combination, and an accommodation groove 21 is provided inside the base 2, and a through hole 22 and an erection hole 23 are respectively provided on the periphery to communicate with the accommodation groove 21;

[0046] A turntable 3 is provided with a slotted hole 31 in its center, and a bearing groove 311 is set in the slotted hole 31 and a first bearing 32 is assembled. 341 meshes, and drives the turntable 3 to rotate through the power motor 34;

[0047] A rotating shaft sleeve 4 is correspondingly installed in the sha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap