Improved structure of full-automatic mesh printing machine

A fully automatic, printing machine technology, used in screen printing machines, printing machines, rotary printing machines, etc., can solve the problem that the desired effect cannot be achieved, the safety of the network transformer cannot be guaranteed, and the safe position of the printing plate cannot be guaranteed, etc. problems, to achieve the effect of eliminating the manual handling process and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

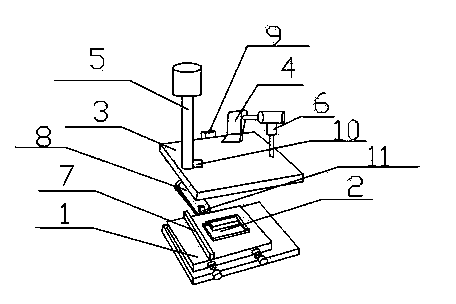

[0018] Such as figure 1 As shown, the present invention includes a worktable 1, a placement table 2, a printing plate 3, a brush 4, a conveyor belt 8 and a displacement sensor 10, the placement table 2 is located at the center of the workbench 1, and a limit position is also installed on the workbench 1. The plate 7 and the limiting plate 7 are parallel to the placing table 2 . The printing plate 3 of this embodiment is located directly above the workbench 1 , the top of the printing plate 3 is connected to the elevating rod 5 , the displacement sensor 10 is located at the bottom of the elevating rod 5 , and a dryer 9 is installed on the side of the printing plate 3 . The brush 4 of this embodiment is connected on the push-pull device 6 of the printing plate 3 . The driving end of the conveyor belt 8 of this embodiment is close to the edge of the workbench 1, and the conveyor belt 8 is provided with a groove, and a matching box 11 is clamped in the groove, and the conveyor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com