Movable truck mounted crane system with power

A mobile, truck-mounted crane technology, applied in the direction of vehicles with cranes, etc., can solve the problem that the mechanized loading and unloading of materials cannot be realized, and achieve the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

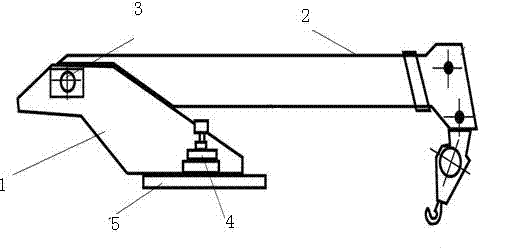

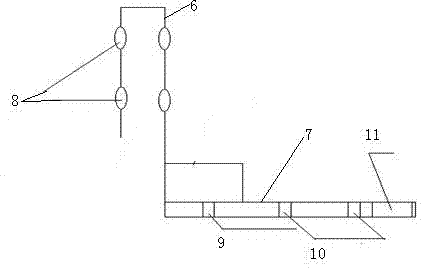

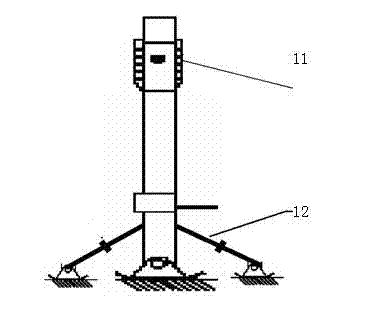

[0019] Such as Figure 1-5 As shown, the system includes a boom mechanism module, a hydraulic support module, a power servo module and a limit locking module; the boom mechanism module includes a rotating arm 1 and a telescopic boom 2, and the telescopic boom consists of a boom casing and a The inner telescopic boom is composed of the rotating arm and the telescopic boom are movably connected through the connecting shaft 3, and the bottom end of the rotating arm is movably connected with the boom chassis 5 through the rotating shaft 4; It consists of four outriggers 12 of hydraulically retractable and foldable support arms, and the outrigger limit plates are fixed on both sides of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap