Storage device of chemical materials for manufacturing automotive interiors

A technology for chemical raw materials and automotive interiors, which can be used in tank trucks, packaging, transportation of passenger cars, etc., and can solve the problems of high cost, increased personnel expenses, and frequent transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

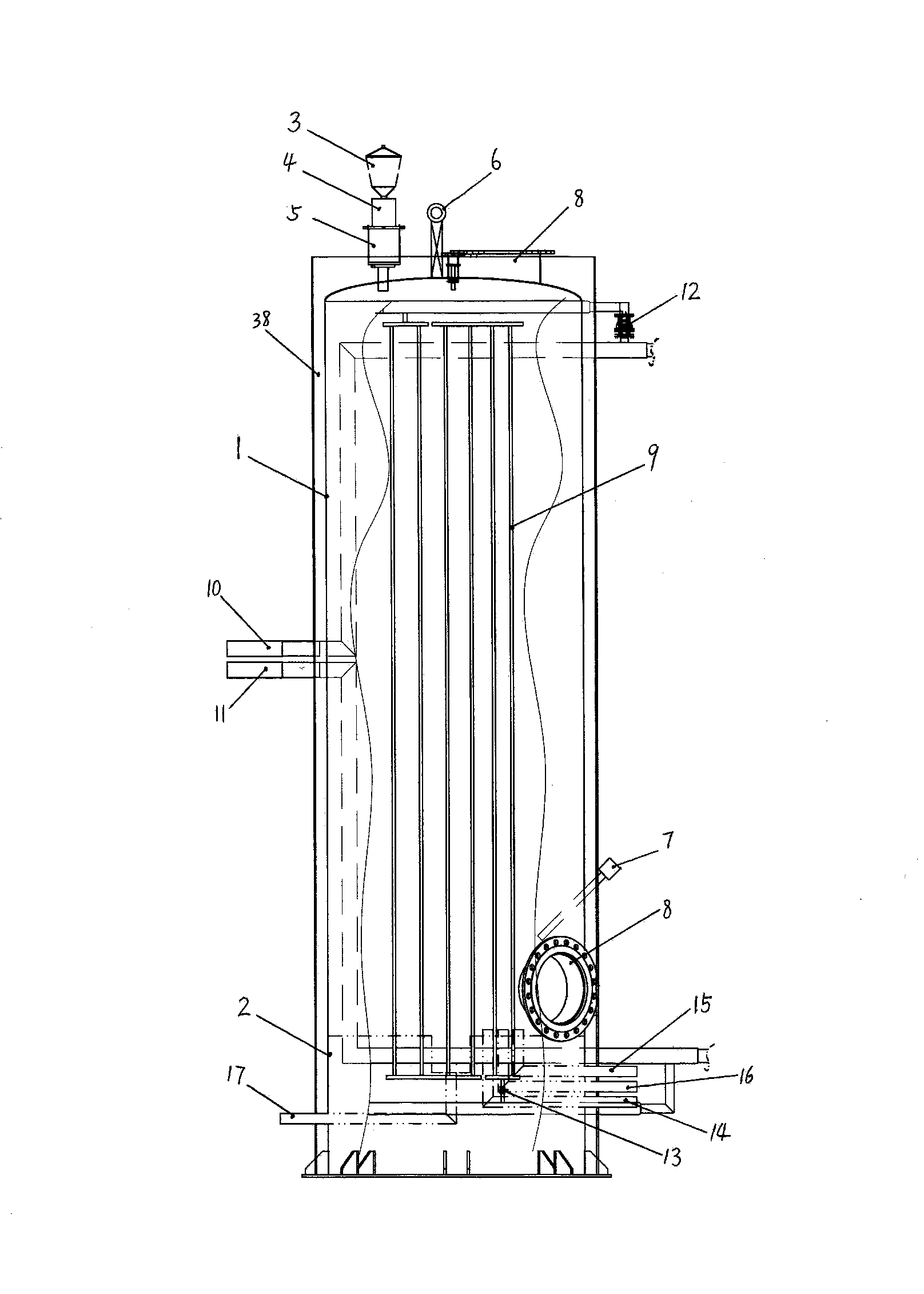

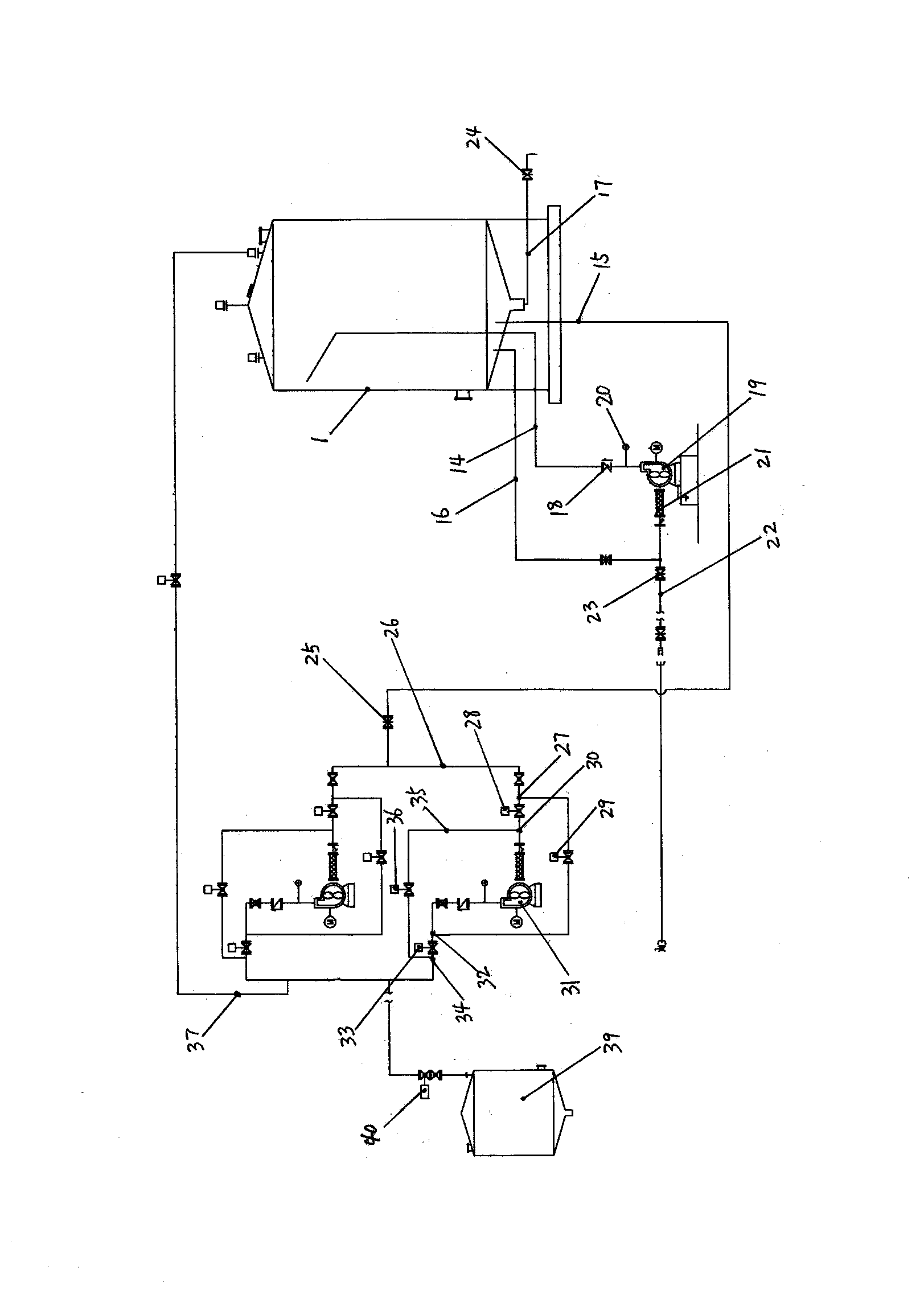

[0019] refer to figure 1 , 2 , which includes the tank body 1 and skirt 2 of the storage tank, the top of the tank body is equipped with a vent valve 3, a drying tank 5, a flame arrester 4, a liquid level controller and a liquid level sensor 6, and a temperature sensor 7 at the bottom of the tank body. There are also manholes 8 on the tank body, and several groups of heating pipes 9 are surrounded around the tank body. The hot water inlet and cold water outlet of each group of heating pipes are respectively connected with the hot water pipe 10 of incoming water and the cold water pipe 11 of return water. There are gate valves 12 on the hot water inlets of the heating pipes of each group, and ball valves 13 are arranged on the cold water outlets of each group of heating pipes; an insulation layer 38 is wrapped around the tank body, and a feed pipe 14 and a discharge pipe 15 are connected on the tank body , circulation pipe 16 and blowdown pipe 17, blowdown gate valve 24 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com