Combined type environment-friendly device using MVR-bipolar electrolysis-biological enhancement technology

A technology of environmental protection equipment and bio-enhancement, applied in the fields of biological water/sewage treatment, water pollutants, chemical instruments and methods, etc., to achieve the effects of easy management, simple operation, and reduced land occupation and investment costs

Active Publication Date: 2014-01-22

TIANJIN UNITED ENVIRONMENTAL ENG DESIGN

View PDF11 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the traditional biological method is almost impossible t

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

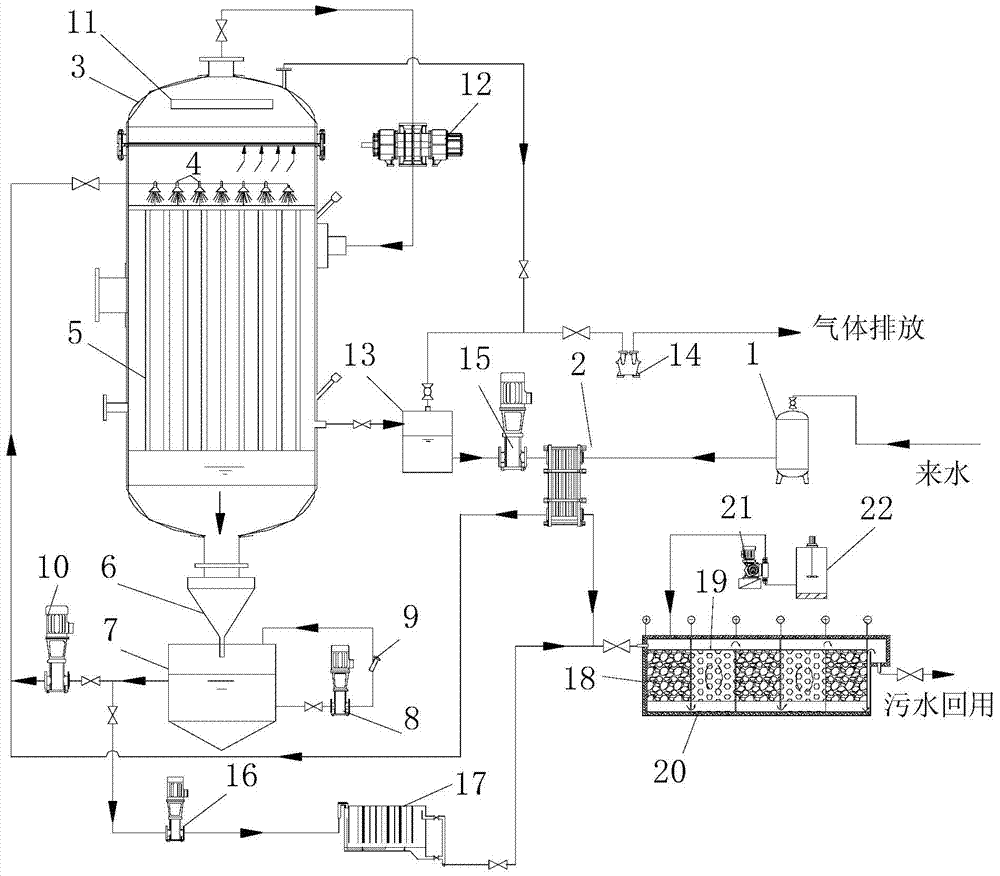

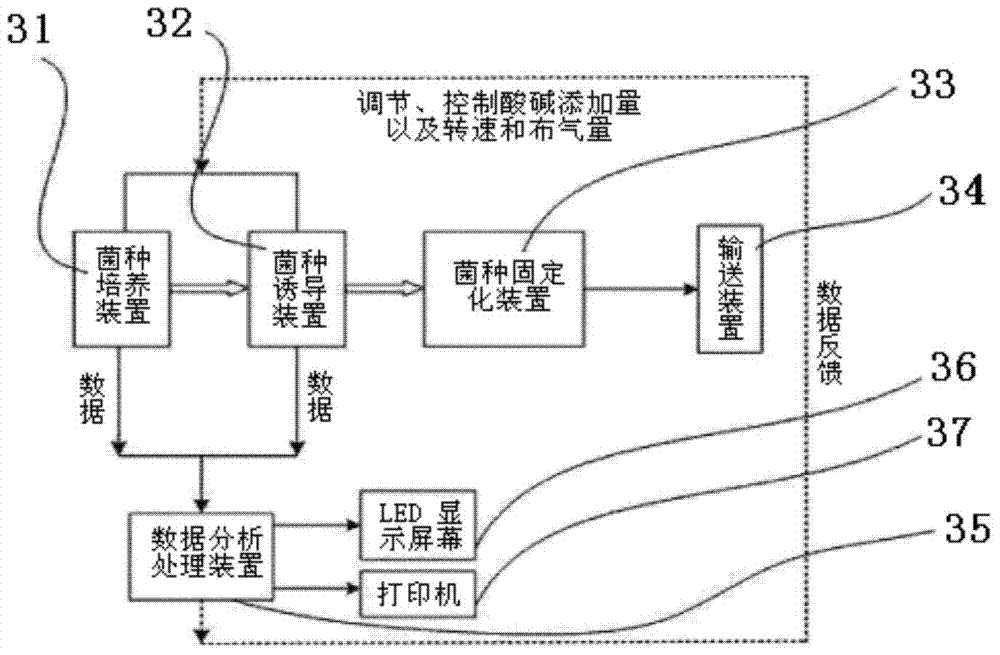

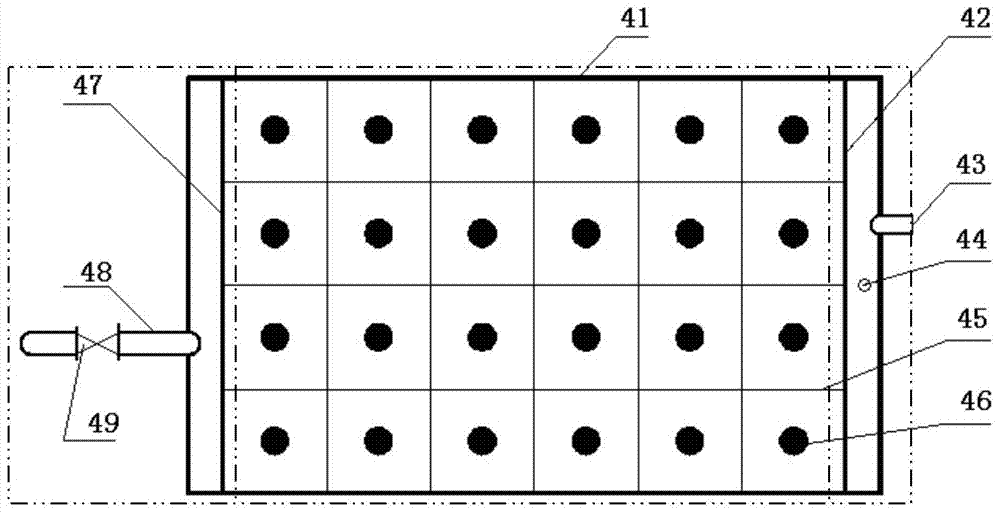

The invention discloses a combined type environment-friendly device using the MVR-bipolar electrolysis-biological enhancement technology. The combined type environment-friendly device comprises a preprocessing unit, an evaporating and concentrating unit, a biochemistry unit and a bipolar electrolysis processing unit, wherein the preprocessing unit, the evaporating and concentrating unit, the biochemistry unit and the bipolar electrolysis processing unit are connected with one another through a pipeline. An MVR unit conducts proper concentration on industrial waste water through the steam recompression technology, distilled water can be recycled or discharged according to the standard, and a concentrated solution enters the bipolar electrolysis processing unit. The mesh-shaped unit type structural design is adopted for the units, the water flow short circuit can be avoided, the mass transfer effect is improved, the oxidoreduction efficiency is ensured, and therefore pollutants are thoroughly removed. An on-line bacterium throwing type membrane biological fixing system is adopted for a biological unit. PVA floating fillers where special efficient bacterium strains are attached are fixed in a biochemical pool, and the organic matter removing effect is enhanced through a timed on-line bacterium throwing system. The combined type environment-friendly device is an integrated device, and the wastewater treatment efficiency and the standard reaching effect are greatly improved when the MVR-bipolar electrolysis-biological enhancement technology is combined with a traditional wastewater treatment technology.

Description

technical field [0001] The invention relates to a system for treating industrial waste water containing refractory organic matter, in particular to a system for treating industrial waste water with a combination of processes. Background technique [0002] With the rapid development of my country's industry, the discharge of high-concentration refractory industrial wastewater has increased dramatically, and the resulting water pollution has become a major problem of environmental pollution in our country. In the national "Eleventh Five-Year Plan" and every subsequent year's environmental planning, the treatment of refractory industrial wastewater has been established as one of the key areas of national policy. [0003] Refractory organic matter refers to organic matter that cannot be degraded by microorganisms or cannot be degraded fast enough to prevent it from accumulating in the environment under any environmental conditions. The so-called refractory (refractory biodegrada...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F9/14C02F1/04C02F1/461C02F3/34C02F101/30

Inventor 余海晨郑先强段云霞彭玲石宇亭曾猛张金鸿孙凯侯霙李立春高玮吕晶华宋薇薇许丹宇石岩邱传勇陈福周

Owner TIANJIN UNITED ENVIRONMENTAL ENG DESIGN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com