A nitriding method

A technology of nitriding and nitrogen atmosphere, applied in coating, metal material coating process, solid-state diffusion coating, etc., to achieve obvious nitriding effect, reduce co-infiltration temperature, easy composition and phase structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

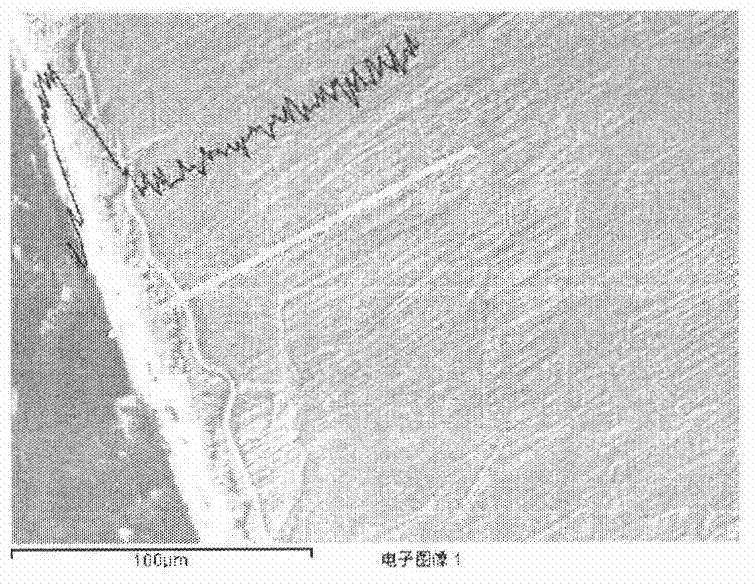

[0041] The catalyst provided by the invention is used for gas nitriding of 316 stainless steel under pure nitrogen atmosphere.

[0042] Catalyst is RT x m y , select 12 kinds of alloys whose atomic ratio of R and T is about 1:13~1:2, the specific chemical composition is: (1) LaFe 11 Si 2 ; (2) CeFe 11 Ti; (3)PrFe 4 Al 8 ; (4) NdFe 9 Cr 2 ; (5) YFe 4 co 5 Si; (6)YFe 8 ; (7) SmFe 8 N 3 ; (8) NdFe 7 BH 3 ; (9) YFe 4 ;(10)SmFe 2 Ni 2 B; (11) YFe 3 ;(12)YFe 2 .

[0043] According to the above chemical formula, after mixing pure metal or intermediate alloy blocks with a purity higher than 99%, alloy ingots are obtained by argon-protected arc melting, and alloy powder slurry is obtained after ethanol-protected ball milling. The average particle size of the powder is 2.3~ 13.6 μm. The alloy containing H or N is treated in pure hydrogen or pure nitrogen atmosphere at 300-600°C for 1-5 hours.

[0044] Add an appropriate amount of polyethylene glycol and ethanol to ...

Embodiment 2

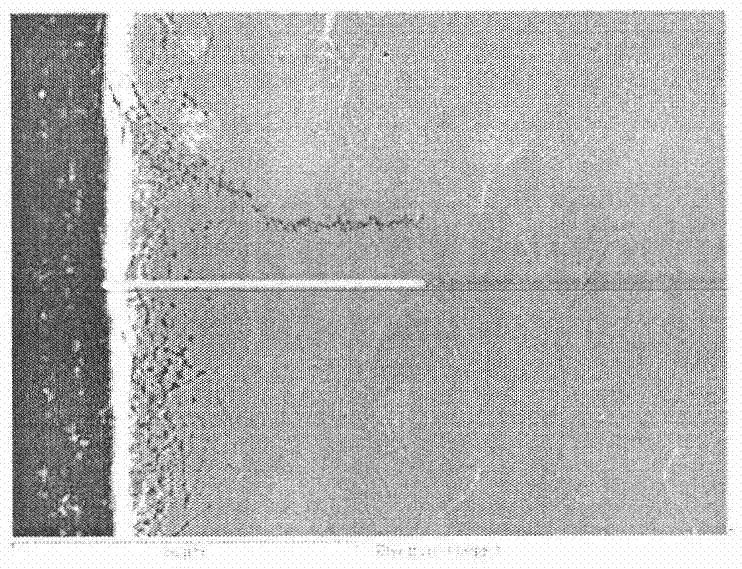

[0054] The catalyst provided by the invention is used for gas nitriding of 316 stainless steel under pure ammonia atmosphere.

[0055] Catalyst is RT x m y , select 12 alloys whose atomic ratio of R and T is about 1:13~1:2, and the specific chemical composition is close to the following ratio: (1) LaFe 11 Si 2 ; (2) CeFe 11 Ti; (3)PrFe 4 Al 8 ; (4) NdFe 9 Cr 2 ; (5) YFe 4 co 5 Si; (6)YFe 8 ; (7) SmFe 8 N 3 ; (8) NdFe 7 BH 3 ; (9) YFe 4 ;(10)SmFe 2 Ni 2 B; (11) YFe 3 ;(12)YFe 2 .

[0056] According to the above chemical formula, after mixing pure metal or intermediate alloy blocks with a purity higher than 99%, alloy ingots are obtained by argon-protected arc melting, and alloy powder slurry is obtained after ethanol-protected ball milling. The average particle size of the powder is 2.3~ 13.6 μm. The alloy containing H or N is treated in pure hydrogen or pure nitrogen atmosphere at 300-600°C for 1-5 hours.

[0057] Add an appropriate amount of polyethylene...

Embodiment 3

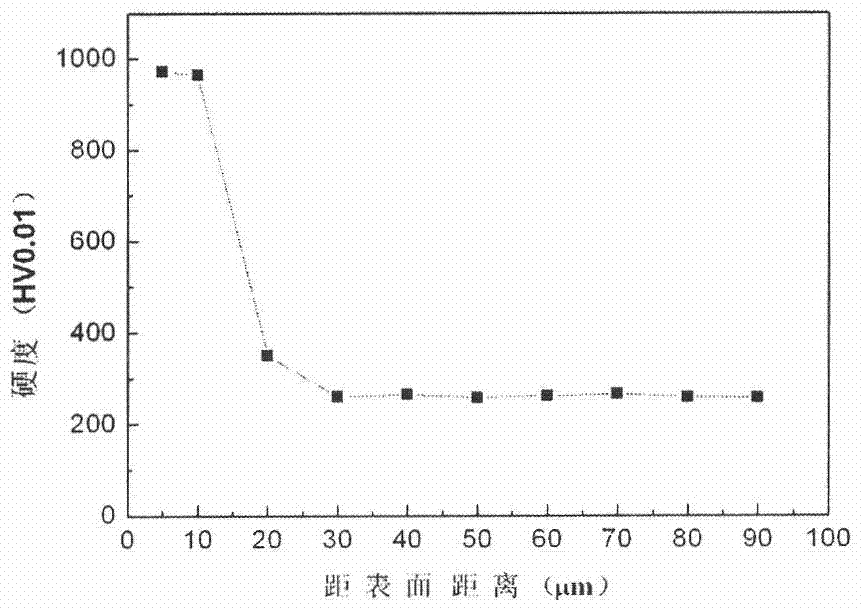

[0067] The catalyst provided by the invention is used for gas nitriding of 316 stainless steel at different temperatures under pure nitrogen atmosphere.

[0068] The selected catalyst is YFe 8 , prepare the alloy powder slurry according to the method described in Example 1, and apply it on the surface of 316 stainless steel.

[0069] Use a tube furnace for nitriding treatment, pre-evacuate to below 0.1Pa, fill with nitrogen with a purity of 99.995%, and the air pressure is 0.1-0.15MPa, hold at 300°C, 500°C, and 700°C for 10 hours, then cool with the furnace .

[0070] According to the method described in Example 1, the thickness of the nitriding layer, microhardness and corrosion weight loss rate of 316 stainless steel after nitrogen nitriding at different temperatures were measured, and the results are shown in Table 3. It can be seen that as the nitriding temperature increases, the thickness of the nitriding layer increases significantly, and the microhardness and corrosio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com