Pipe bridge hanging system

A pipeline bridge and saddle technology, applied in bridges, bridge parts, bridge applications, etc., can solve the problems of long cycle, high strength and specification requirements of steel cables, large space for temporary towers and temporary ground anchors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

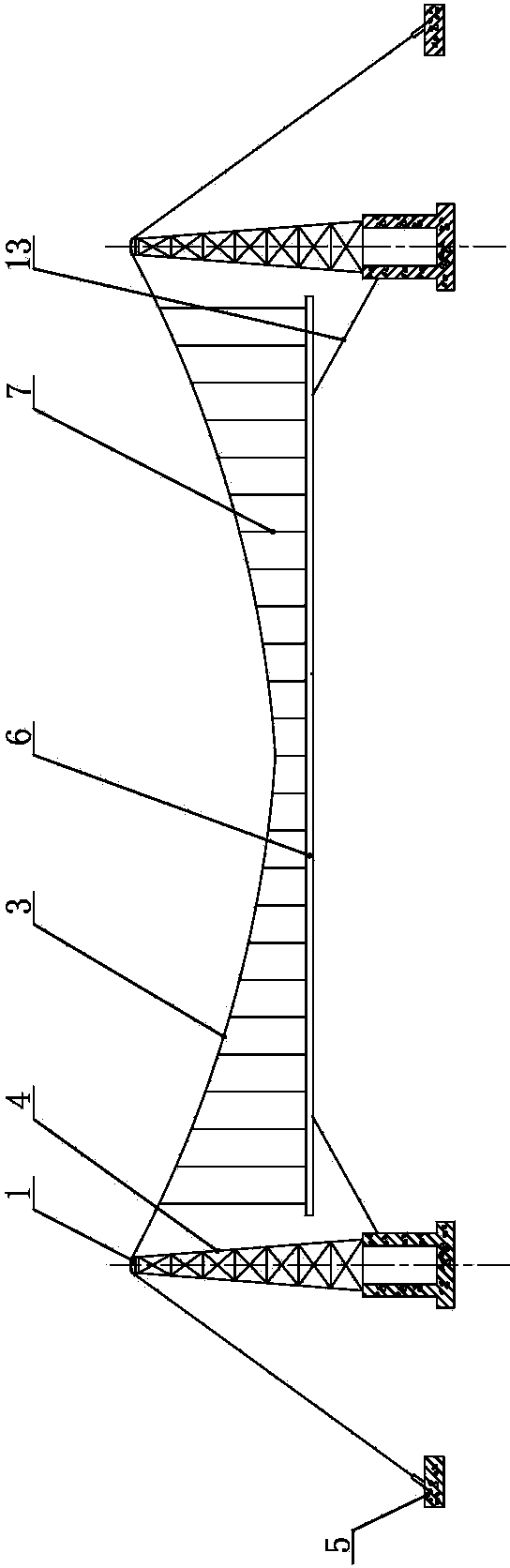

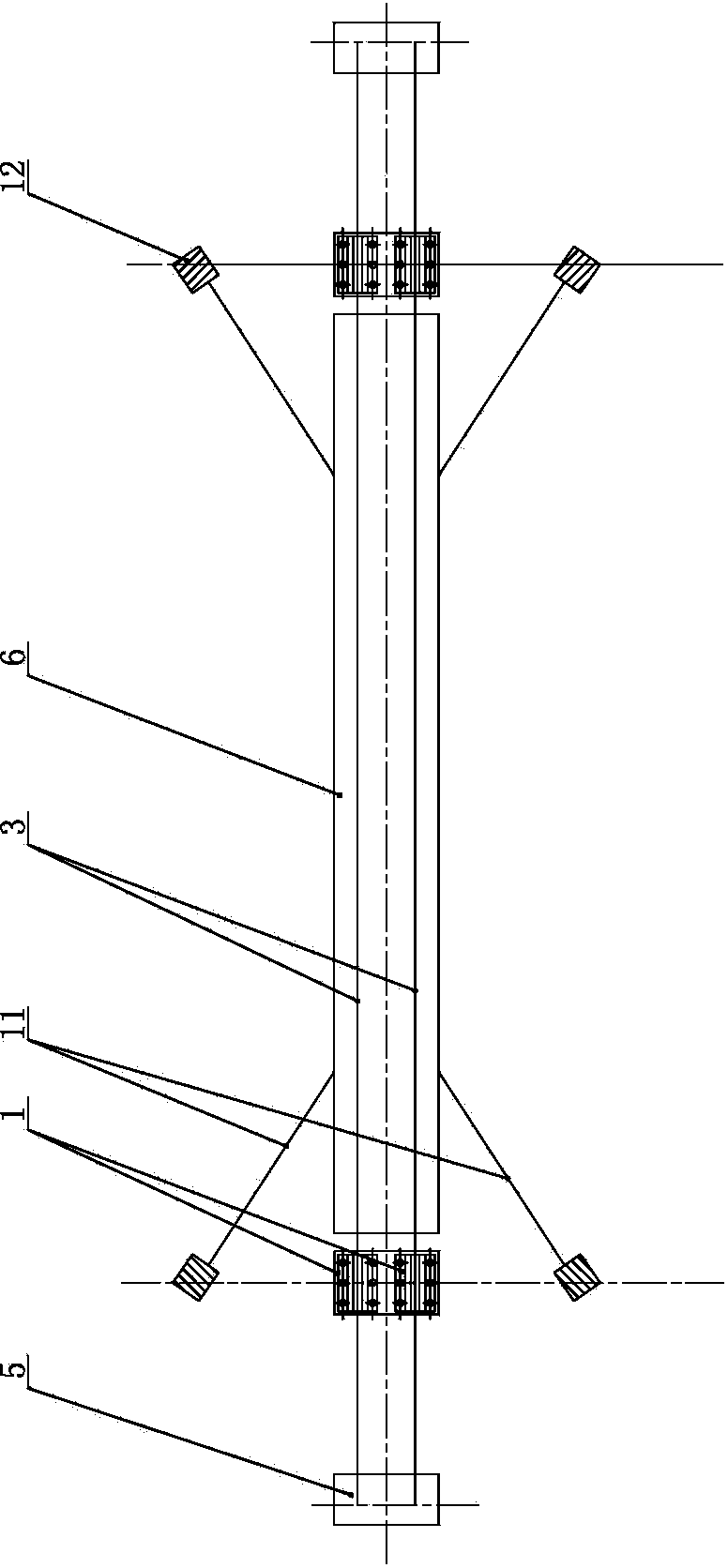

[0031] Such as figure 1 , figure 2 As shown, the suspension system of the pipeline bridge of the present invention comprises a tower 4 positioned on both banks of the river and a pipeline bridge 6 between the two towers. It includes two ground anchor screw rods 5a, the two ground anchor screw rods 5a are parallel to each other and the upper ends point to the saddle device, and the middle parts of the two ground anchor screw rods 5a are jointly screwed with a cable-anchor connecting block 5b.

[0032]A saddle device is respectively fixed on the top platform of each tower frame 4, and a plurality of suspenders 7 are respectively connected to both sides of the pipeline bridge 6 in the width direction, and the upper parts of each suspender 7 are respectively fixedly connected with corresponding steel cables, and the two steel cables are in the The upper part of the river is in the shape of a suspension cable with a low middle and high ends.

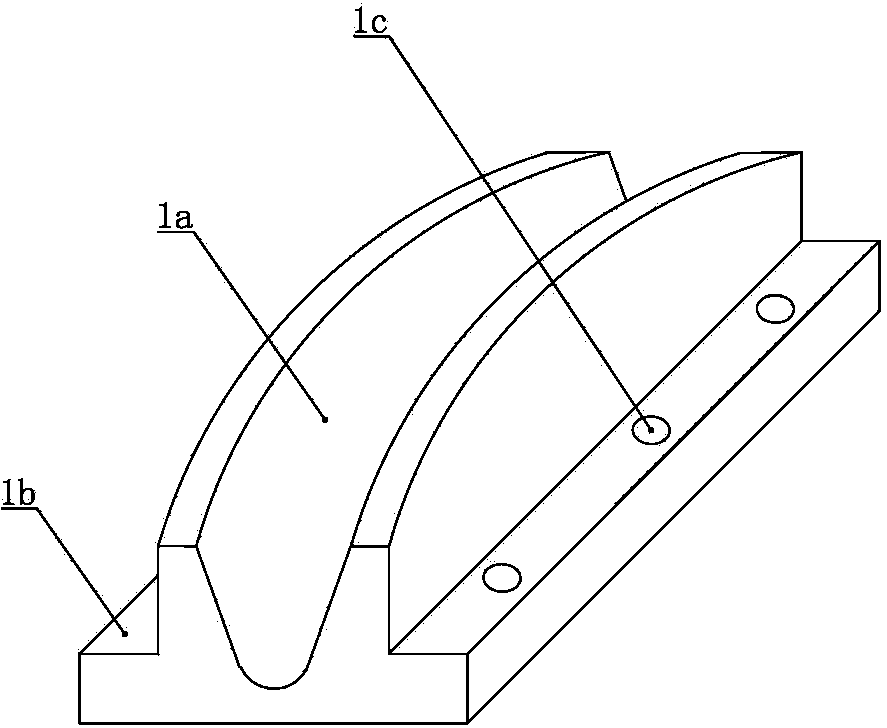

[0033] The saddle device includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com