Membrane type automobile clutch

A clutch and diaphragm type technology, which is applied in the field of auto parts, can solve the problems of easy rupture of the inner support ring, troublesome and laborious prying of the tongue, and large disassembly workload, so as to improve the safety and reliability, and achieve a simple structure. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

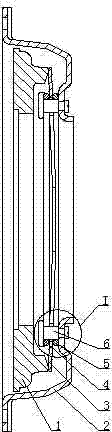

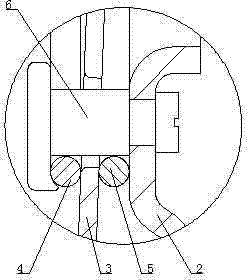

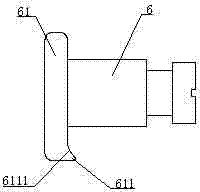

[0009] see Figure 1 to Figure 3 , the present invention includes a pressure plate 1, a clutch cover 2, a diaphragm 3, an inner support ring 4 and an outer support ring 5, and also includes several diaphragm rivets 6 uniformly distributed in the circumferential direction, and the left end of the diaphragm rivet 6 is provided with a shoulder 61. On the right end surface of the shoulder 61, there is a pointed protrusion 611 with tooth tip facing right. The pointed protrusion 611 is provided with a concave arc surface 6111. The diaphragm rivet 6 is sequentially arranged from left to Right connect the inner supporting ring 4 , the diaphragm 3 , the outer supporting ring 5 and the clutch cover 2 , and make the concave arc surface 6111 on the diaphragm rivet 6 closely adhere to the inner supporting ring 4 . The radius of the concave arc surface 6111 on the diaphragm rivet 6 is slightly larger than the radius of the steel wire of the inner supporting ring 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com