Rotatable worktable structure for comprehensive assembly work

A technology for rotating workbenches and work, which is applied to workbenches, manufacturing tools, hand-held tools, etc. It can solve the problems of inconvenient access to tools, affecting operations, and difficult fixing of parts, and achieves the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

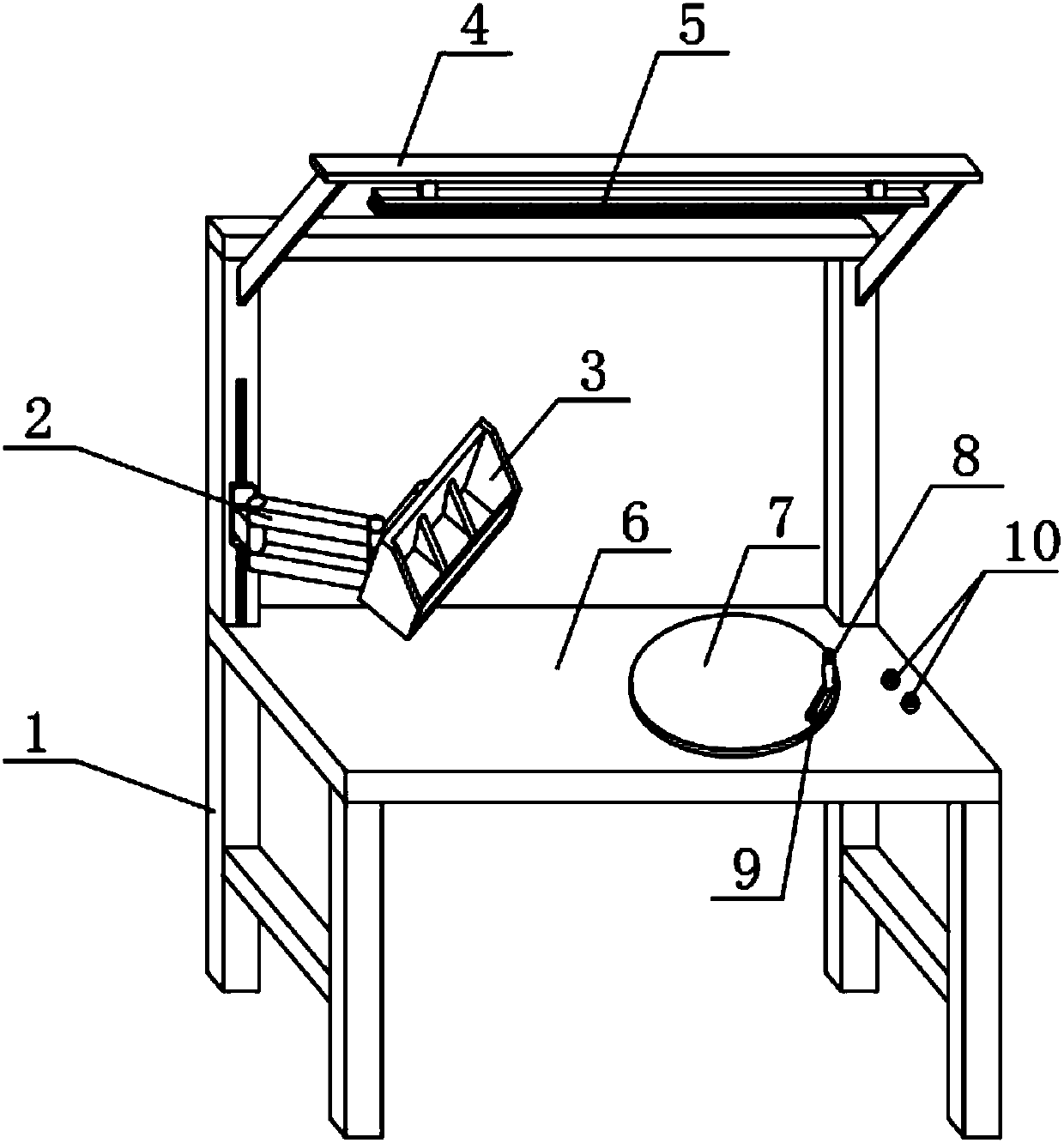

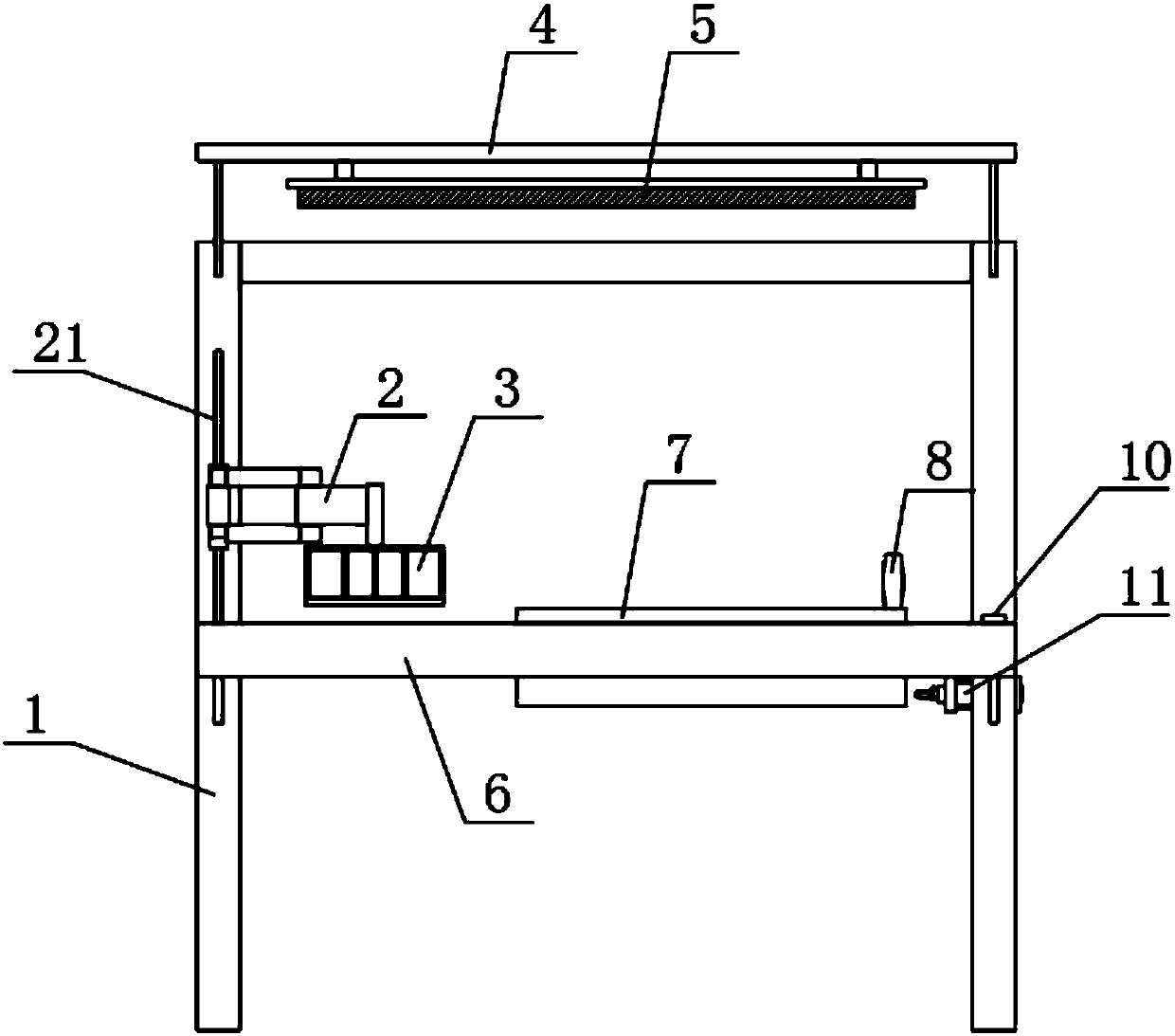

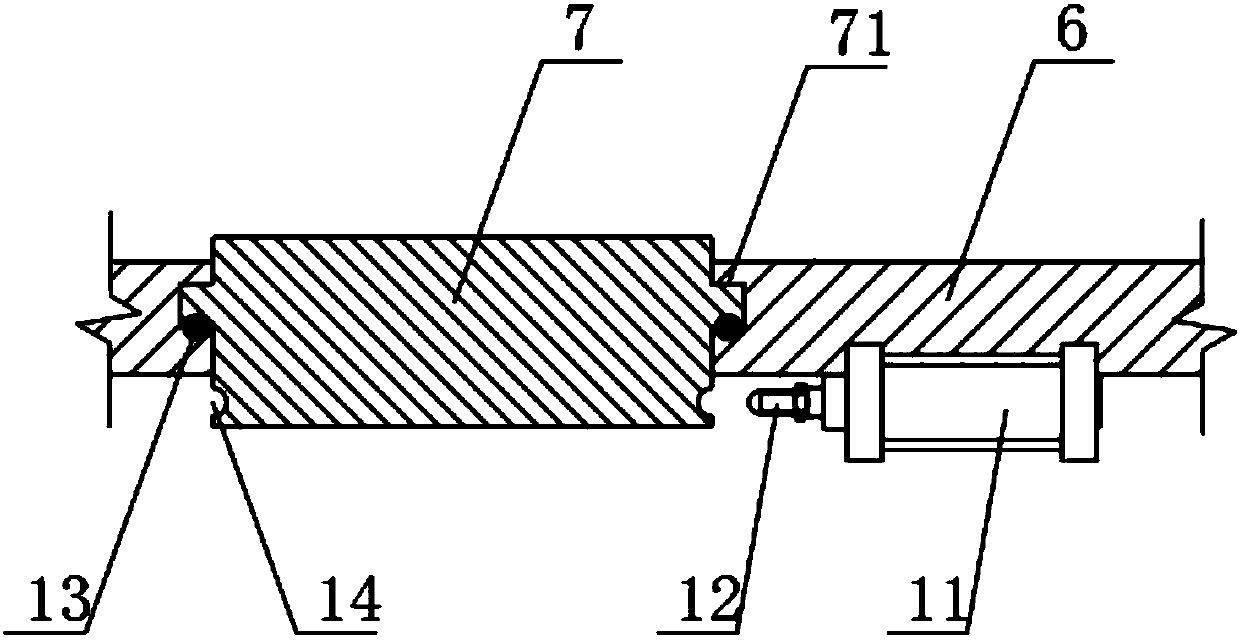

[0022] as attached figure 1 to attach image 3 Shown:

[0023] The invention provides a rotatable workbench structure for comprehensive assembly work, comprising a stand 1, a material frame support 2, a chute 21, a material frame 3, a lighting lamp frame 4, a lighting lamp 5, a table top 6, a turntable 7, a convex Table 71, handle 8, dark groove 9, control button 10, cylinder 11, push rod 12, ball 13 and arc groove 14; Described material frame support 2 is fixedly installed on the column of platform 1; Described material frame 3 Installed on the end of the material frame support 2; the illuminating lamp 5 is installed on the top of the stand 1 through the illuminating lamp holder 4; the turntable 7 is arranged on the right side part of the table top 6; A boss 71 larger than the surface diameter of the turntable 7, and a ball 13 is provided at the bottom of the boss 71; the table top 6 is provided with a rolling groove corresponding to the ball 13, and the turntable 7 is embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com