Electroacoustic transducer

a transducer and electroacoustic technology, applied in piezoelectric/electrostrictive transducers, generators/motors, instruments, etc., can solve the problems of large number of parts, large complex assembly, etc., and achieve the reduction of the overall size, the number of required parts, and the effect of simple structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

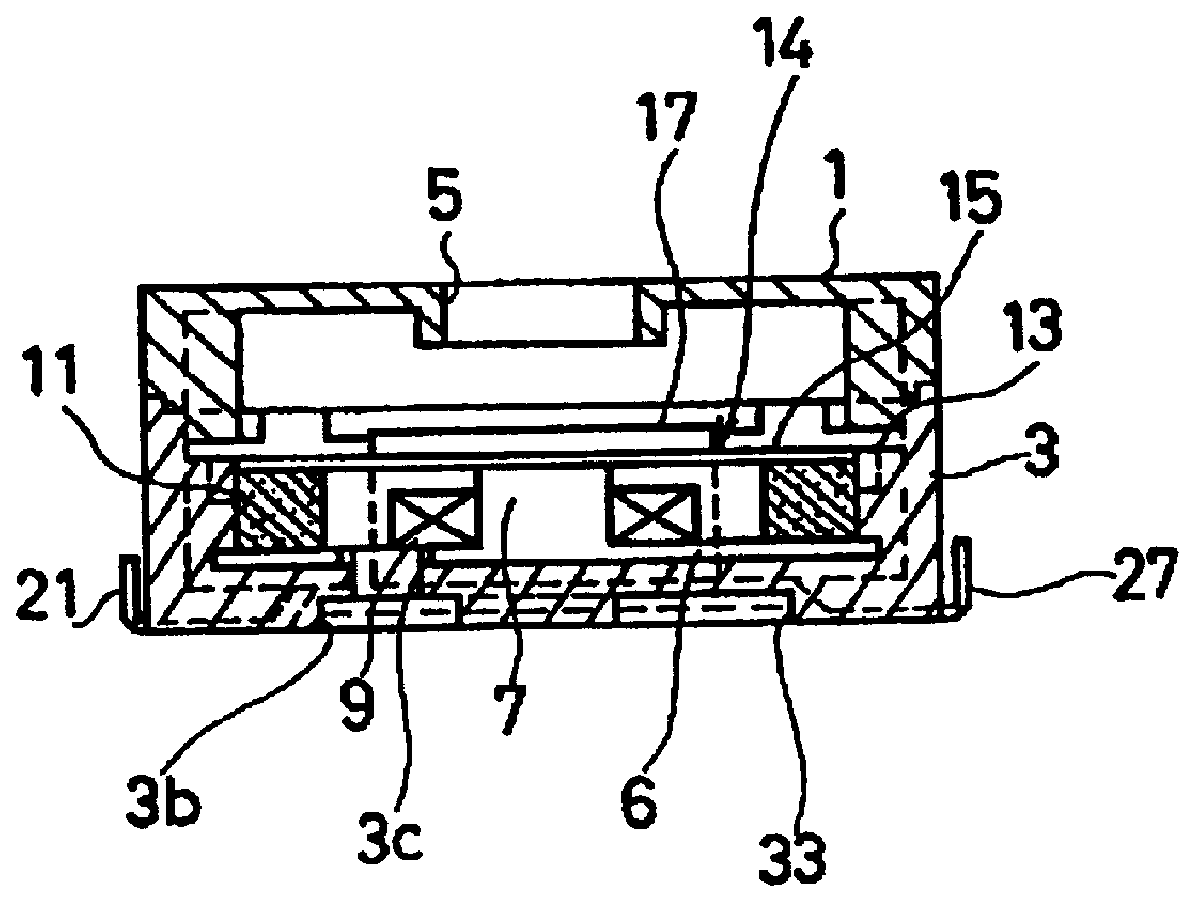

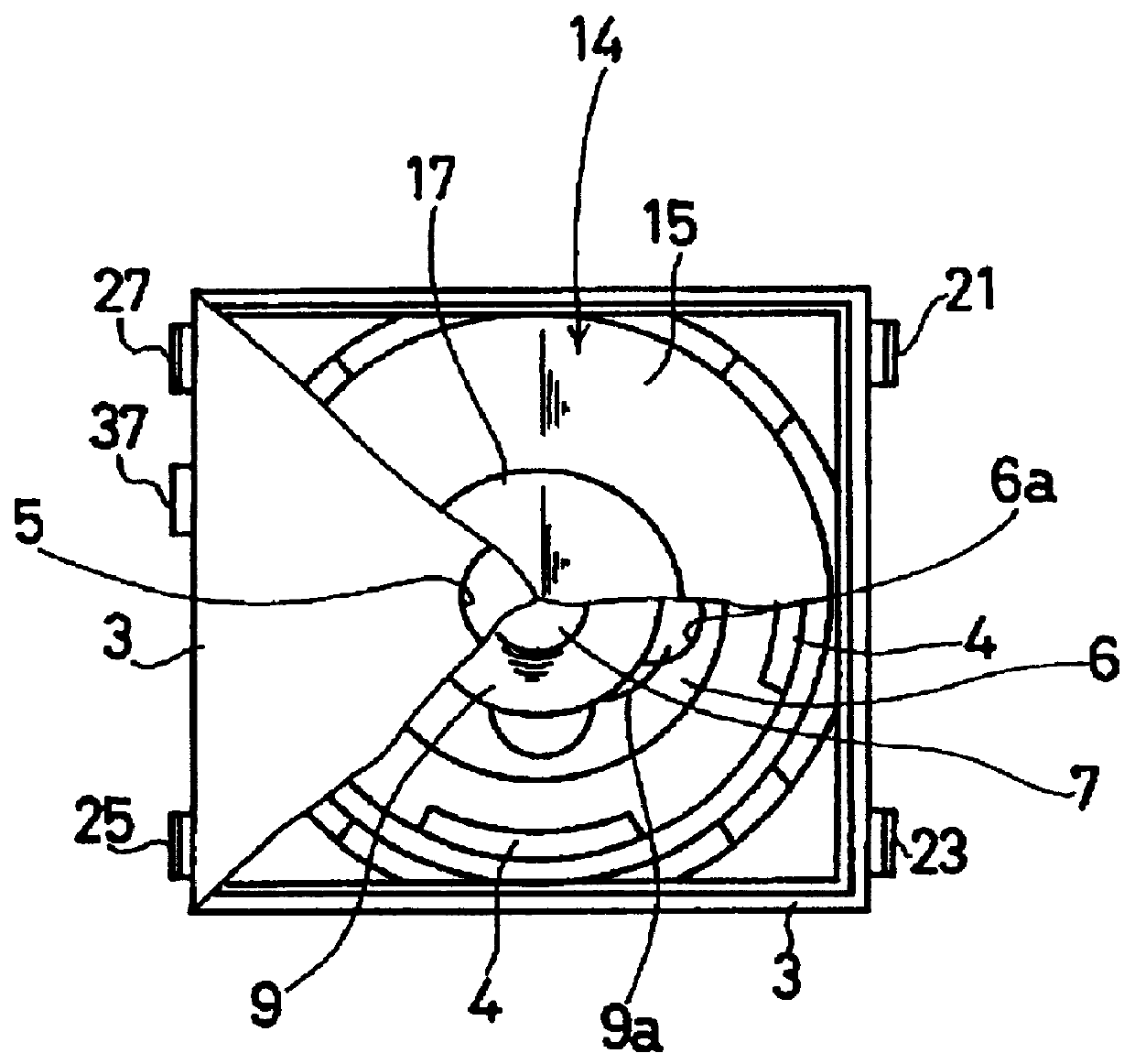

The first embodiment of the present invention will now be described with reference to FIGS. 1 through 7. To begin with, the structure of an electromagnetic type electroacoustic transducer according to this embodiment will be discussed referring to FIGS. 1 to 4. As shown in FIGS. 2 and 3, there are an upper case 1 and a lower case 3, with a circular sound port 5 formed in the center of the top face of the upper case 1 in FIG. 2. A base 6 and a core 7 are arranged at the center portion in the lower case 3 in a securely integrated manner, and a coil 9 is wound around the core 7. A magnet 11 is placed around the coil 9 at the inner wall of the lower case 3. As shown in FIG. 3, the magnet 11 is supported at its outer periphery by four support portions 4 (see FIG. 3) protrusively provided on the inner wall of the lower case 3. Formed on the inner wall of the lower case 3 is a step portion 13 at which a diaphragm 14 is provided, as shown in FIGS. 2 and 3. This diaphragm 14 comprises an ela...

case 3

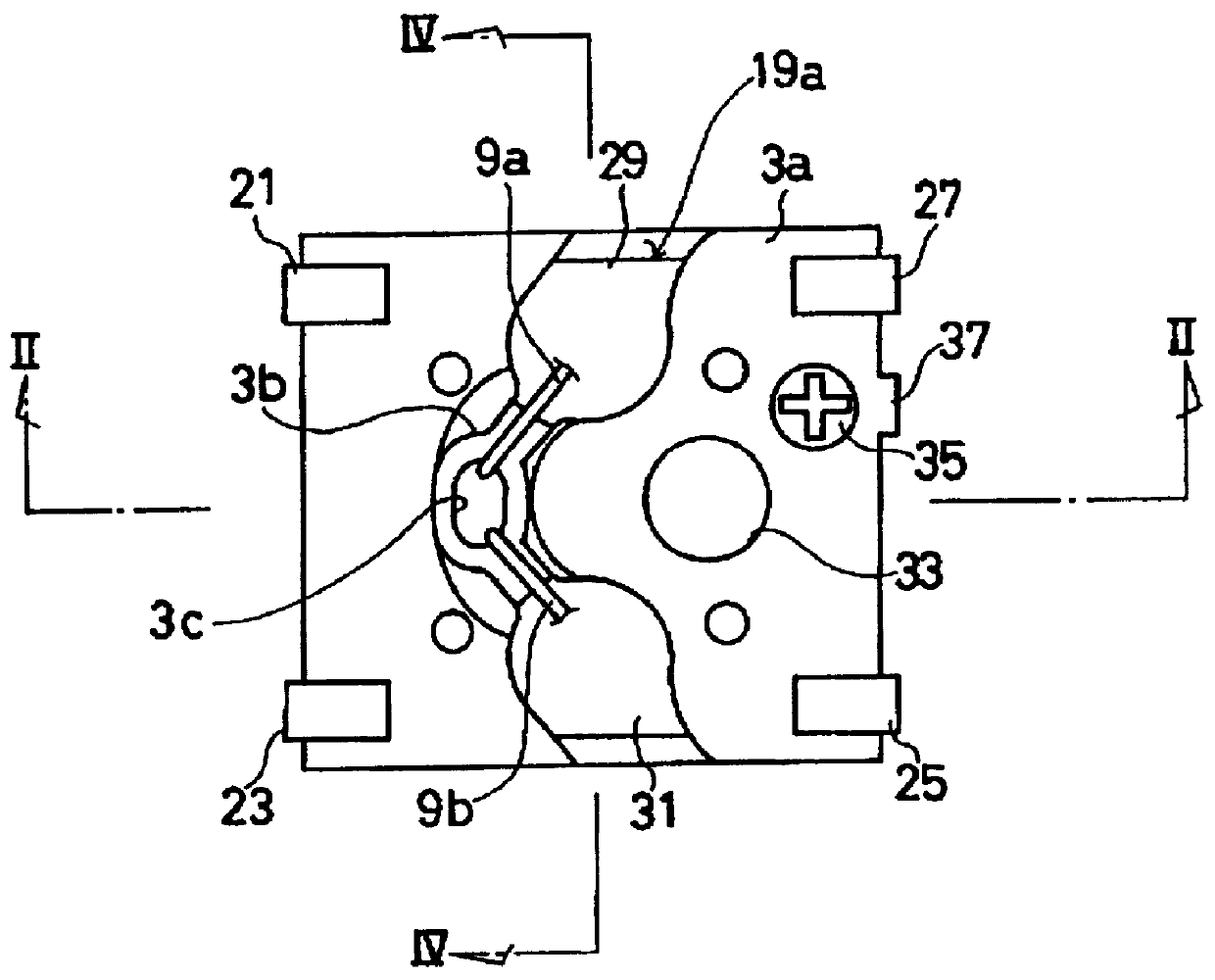

The lower case 3 has the bottom structure as shown in FIG. 1 as seen from the bottom side. The lower case 3 has a bottom wall 3a in which a groove 3b is formed. An opening 3c is formed in the center portion of this groove 3b.

An opening 6a (shown in FIG. 3) is likewise formed in the base 6 located on the inner side of the bottom wall 3a, and the opening 3c is formed at the position matching with the opening 6a.

The groove 3b obliquely extends nearly symmetrically in the up-and-down direction with the opening 3c at the center in FIG. 1. A part of a lead frame element 19a of a lead frame 19 shown in FIG. 5 is integrally buried in the bottom wall 3a by insertion. The four corner portions of the lead frame element 19a are exposed on the lower case 3 as external connection terminals 21, 23, 25 and 27. Some other parts of the lead frame element 19a are exposed in the groove 3b as lands 29 and 31.

Both coil terminals 9a and 9b of the coil 9 accommodated in the lower case 3 are led out to the ...

second embodiment

Referring to FIG. 8, the second embodiment of this invention will be described below. Although the terminal disposal section of a coil is located at the back of the lower case 3 in the first embodiment, the position is not particularly limited to this location. In the second embodiment, the opening 3c is formed in one side wall of the lower case 3 and a pair of lands 29 and 31 of the lead frame element 19a are exposed with the opening 3c in between.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com