Biomedical machinery and equipment clean system safety valve

A mechanical equipment, biomedical technology, applied in the direction of mechanical equipment, safety valves, valve details, etc., can solve the problems of reduced sensitivity, unsmooth movement, increased energy consumption, etc., meet high hygiene requirements, rigorous and novel design, Turn on pressure for accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

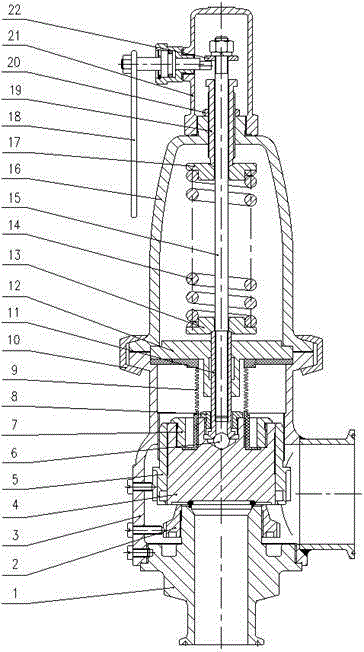

[0018] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0019] according to figure 1 As shown, the safety valve of the biomedical mechanical equipment cleaning system includes a valve body 3, a valve cover 16, and a valve stem 15, and the valve stem is arranged inside the valve cavity formed by the fastening of the valve body and the valve cover; The lower end is connected to the valve disc 4 through the guide sleeve 11, and the bottom of the valve disc 4 abuts against the top of the valve seat 1 connected with the valve body 3 at the same time; the outer circumference of the valve stem is covered with a spring 14, and the upper end of the spring passes through the The spring seat 17 abuts against the bottom of the adjusting screw sleeve 19 which is also set on the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com