Swallow-shaped vortex fin

A swallow-shaped and finned technology, which is applied in the field of aviation airborne equipment reliability, can solve the problems of reduced aircraft performance, high oil temperature, poor heat dissipation, etc., to improve the heat transfer efficiency of the shell, increase the heat transfer, Create a convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the drawings and specific embodiments.

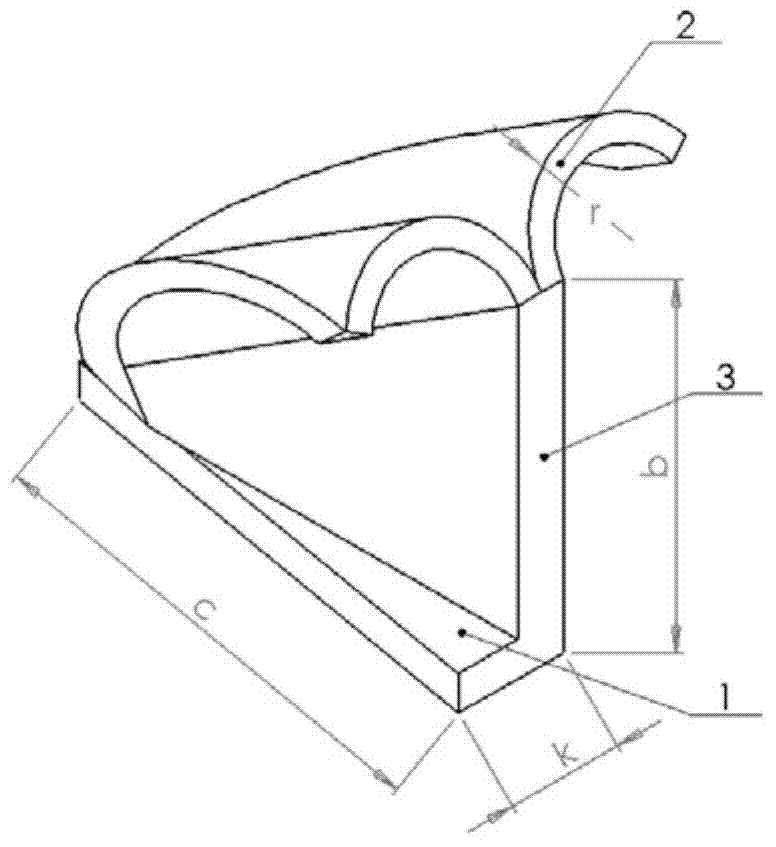

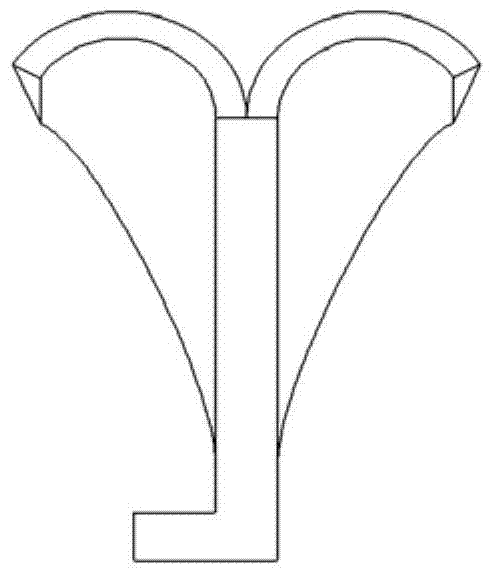

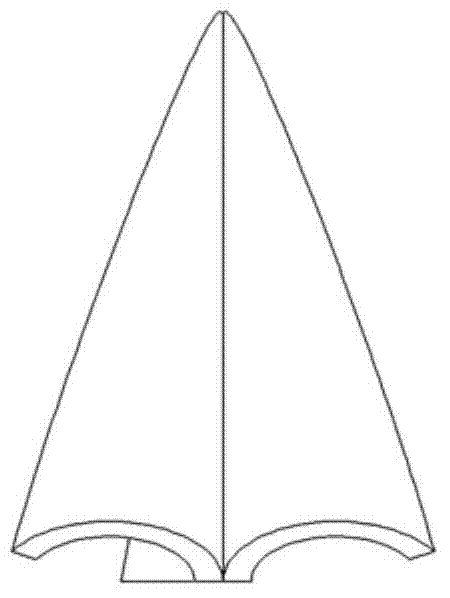

[0017] The structure of the embodiment of the present invention is as figure 1 And Figure 2 (a), Figure 2 (b), Figure 2 (c) shown. Distributed symmetrically on both sides, it is composed of a triangular base 1, a swallow-shaped wing 2 and a triangular rib 3, which are connected to each other. The triangular rib 3 is a triangular structural member, the bottom side of which is vertically connected with the triangular base 1 and the hypotenuse is connected with the bottom of the dove-shaped wing 2 and supports the dove-shaped wing 2 on the triangular base 1. The swallow-shaped wings 2 are two arc-shaped connecting pieces with a radius r, which induce laminar air into turbulent flow. The triangular base 1 is a triangular structural member, which only serves to fix the dove-shaped vortex fins. In order to reduce the quality of the fins, the size and weight of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com