Testing device for detecting impact friction abrasion of workpiece

A technology of impact friction and test device, which is applied in the direction of testing wear resistance, etc., can solve the problem of single test device, and achieve the effect of simple and reliable operation, compact structure and saving abrasives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

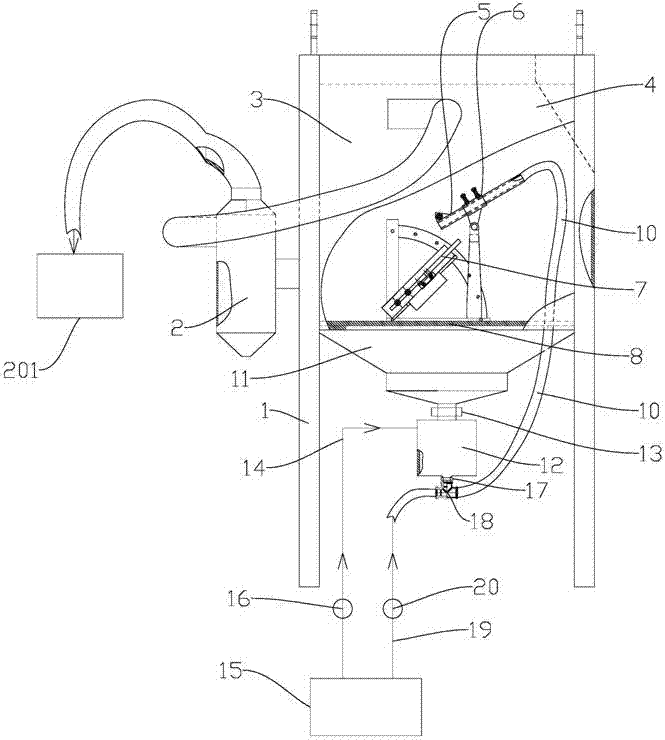

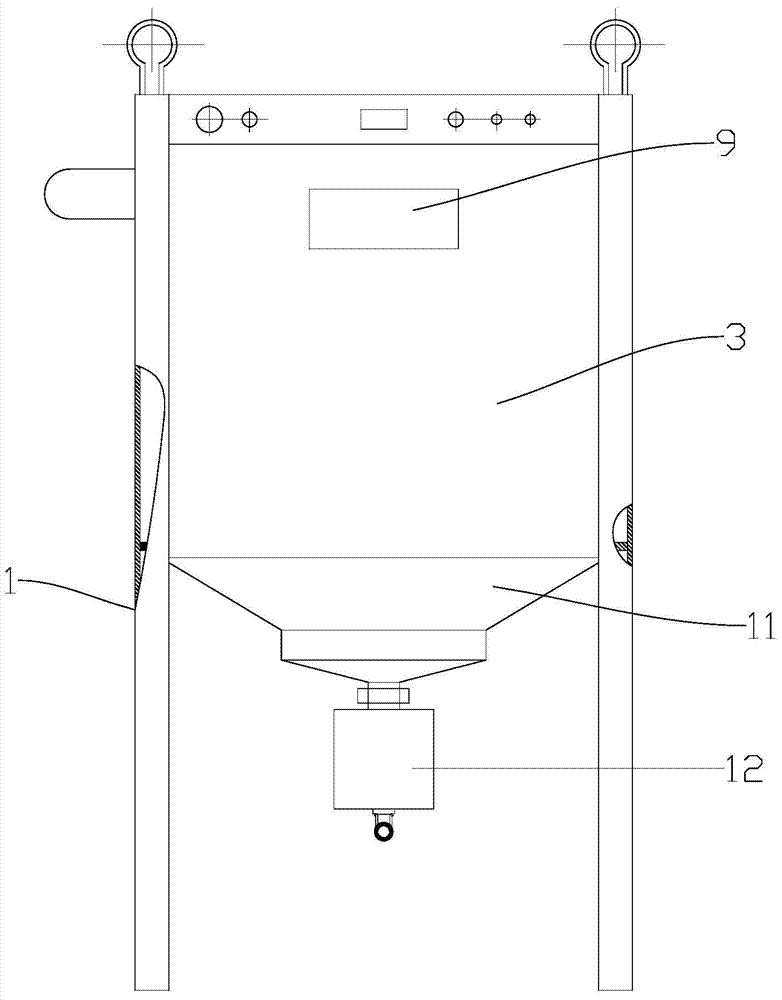

[0054] like figure 1 , 2 As shown, the test device for detecting the impact, friction and wear of workpieces mainly includes a frame 1, a working chamber 3, and a dust collector 2.

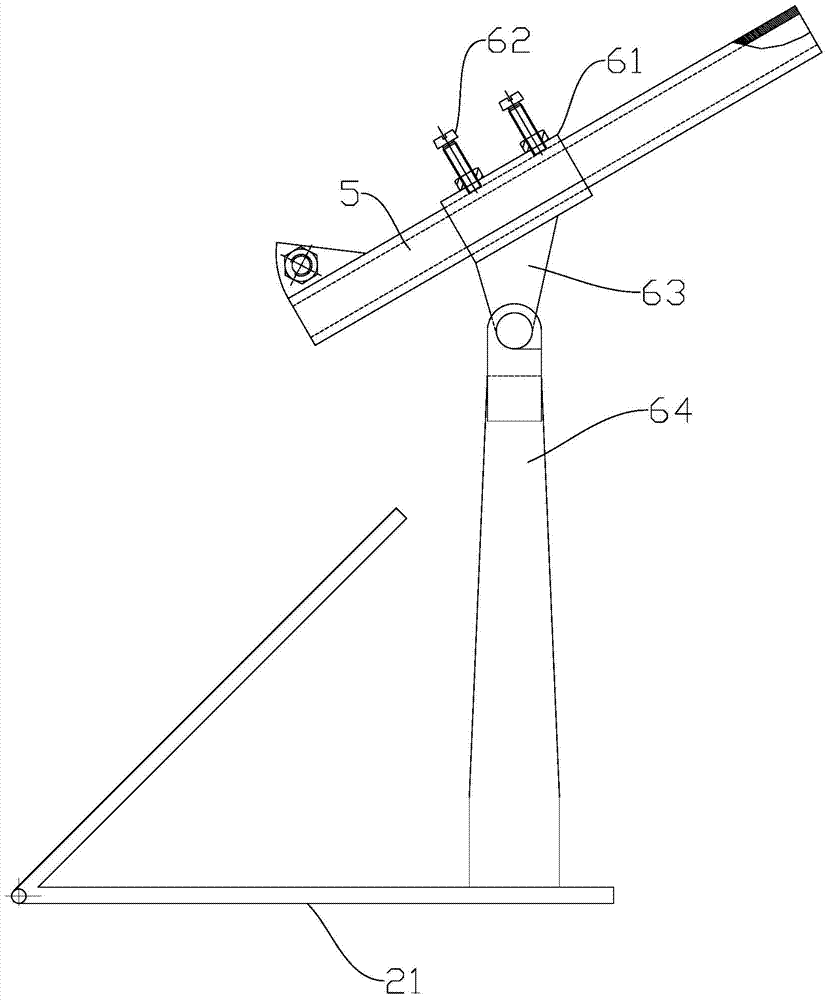

[0055] The working room 3 is installed on the frame 1 . The working room 3 includes a box body 4 , an abrasive output nozzle 5 , an abrasive output nozzle fixture 6 , and a sample fixture 7 .

[0056] The box body 4 is provided with a door that can be locked and sealed. The casing 4 of the working room is provided with a window 9, and a transparent plate is sealed and installed on the window.

[0057] The bottom surface of the box body 4 is provided with a sand drain plate 8 for abrasive recovery, and the sand drain plate 8 is provided with several sand drain holes for draining the abrasive material.

[0058] The abrasive output nozzle 5 is a hard pipe, the front end is a discharge port 51, and the rear end is connected with the feeding pipe 10; the feeding pipe 10 extends to the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com